4. Install the No. 1 injection pipe and tighten to

specified torque.

Do not overtighten the delivery valve holder. It will

distort the injection pump body shape and adversery

affect control rack operation.

Injection pipe nut torque (kgƒUm)

3¡›3.5

(21.7~25.3 lb¡⁄ft)

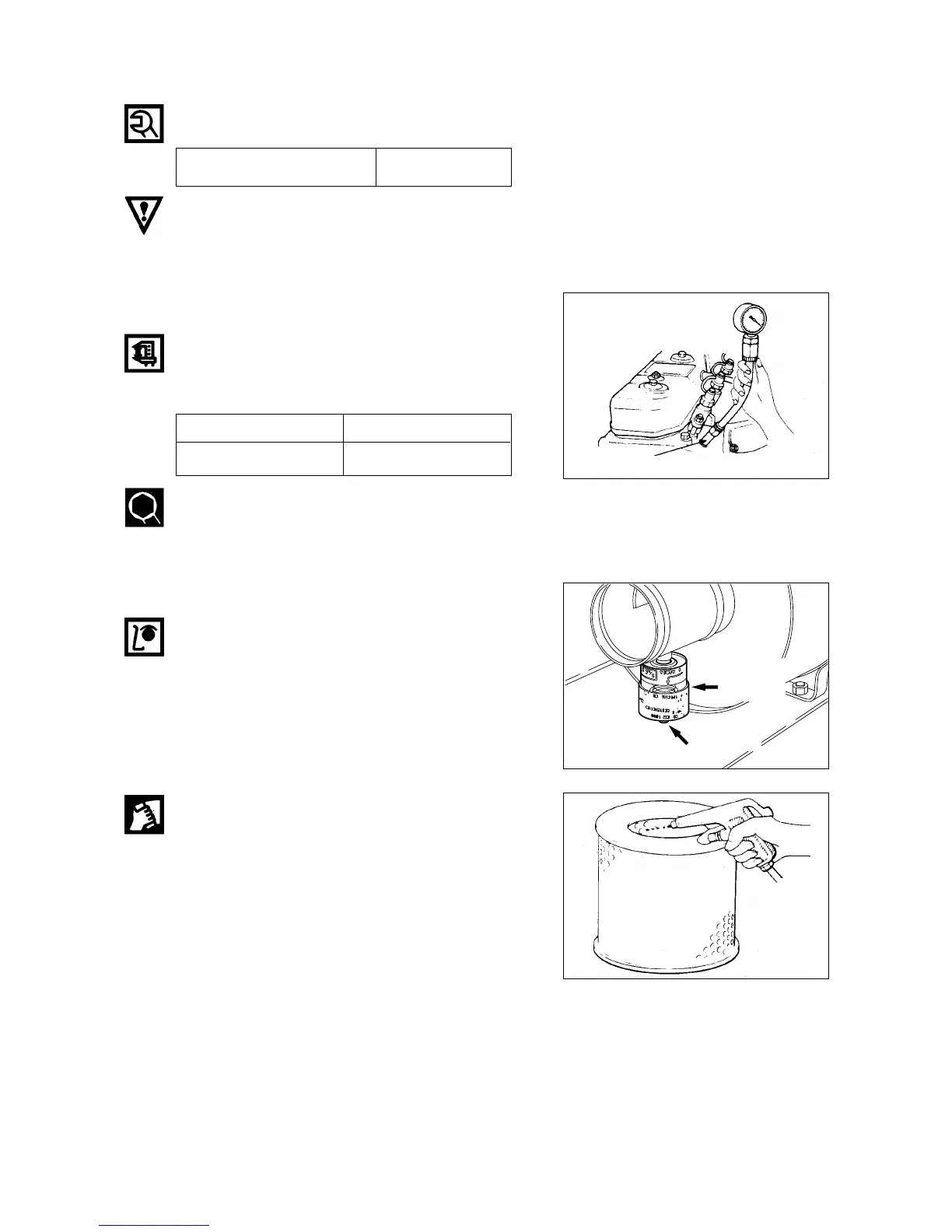

1.6.4. Compression Pressure

Remove the glow plugs from all cylinders, then check

the compression pressure in each cylinder with a

compression gauge by engaging starter.

(kg/cm

2

, 200 rpm)

Compression gauge adapter

Standard

30

Limit

22¡›23

(312~327 psi)

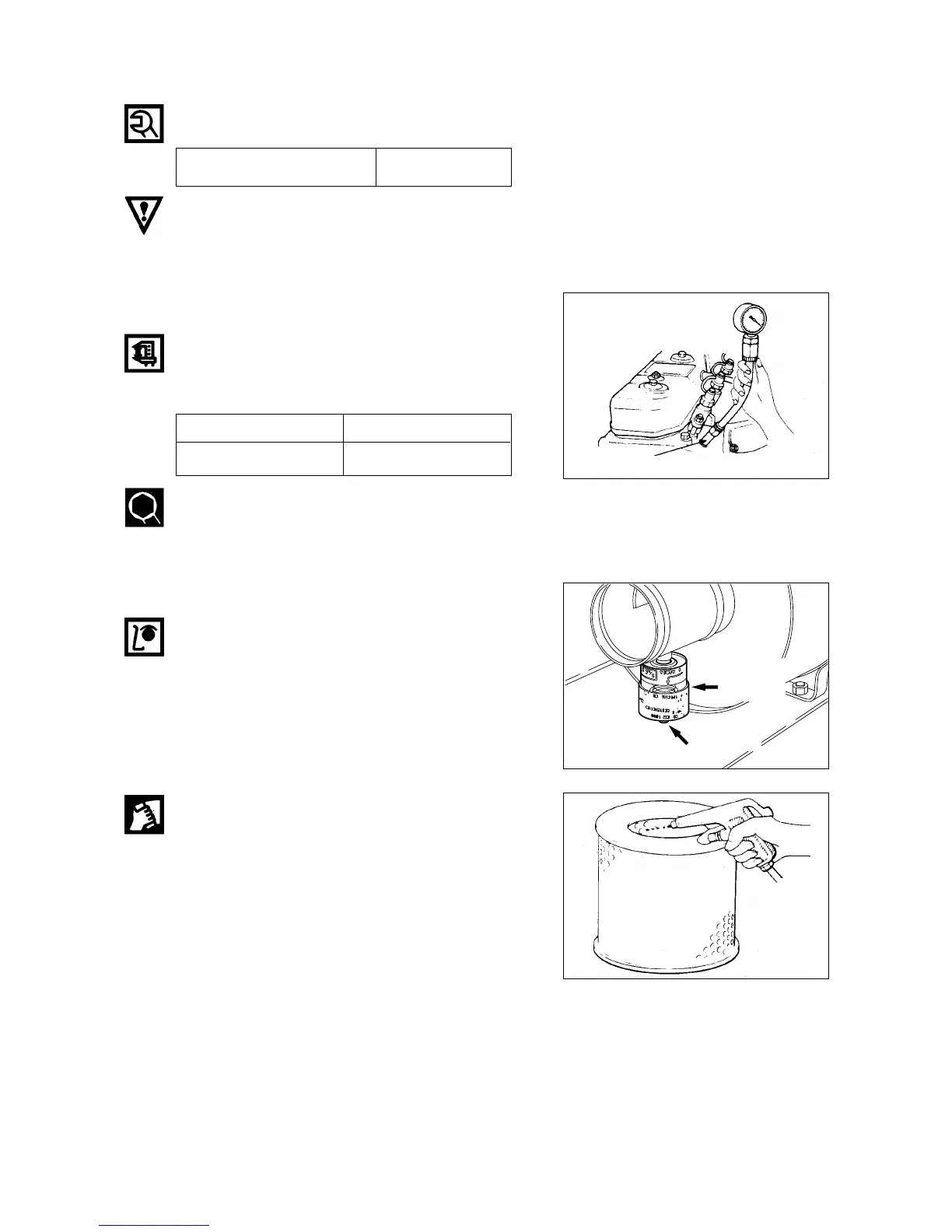

1.6.5. Air Cleaner

Dry type air cleaner

¡

Observe the air cleaner service indicator

¡

Clean the air cleaner element and dust pan when the

RED band in the service indicator looks in the visible

position.

Cleaning primary filter element

¡

Direct air inside of the element and blow out dusts

from the pleats completely.

(Maximum air pressure does not excess 2.1kg /cm

2

)

¡

Always replace the secondary element.

Do not attempt to reuse it by cleaning.

Compression gauge adapter

Loading...

Loading...