39

Bushing replacement

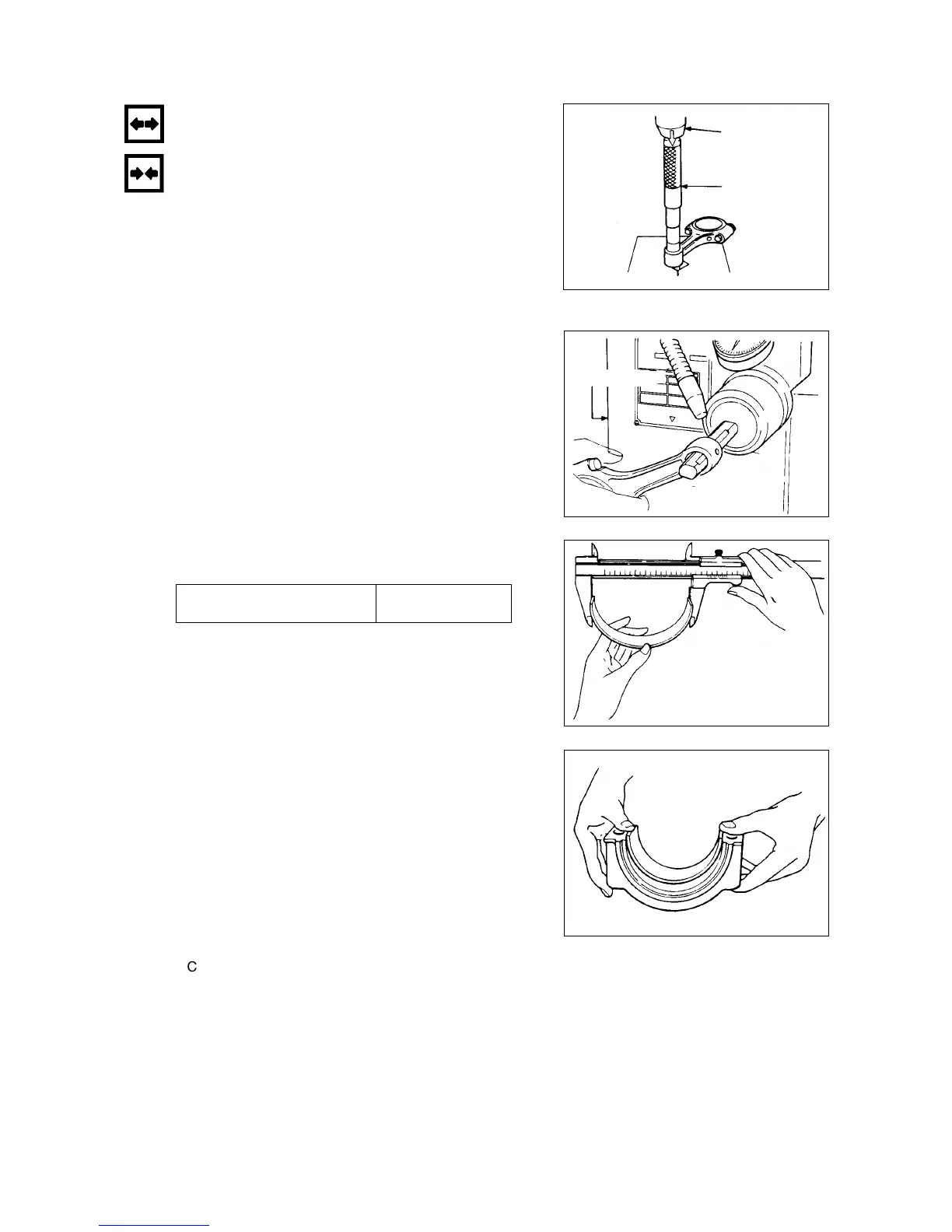

Removal : Use a brass bar and a bench press

Installation : Use a brass bar and a bench press. The

connecting rod busing oil port must be

aligned with the connecting rod oil port.

After new bushing installation, ream the bushing

inside diameter with a pin hole grinder or a reamer to

fit the piston pin.

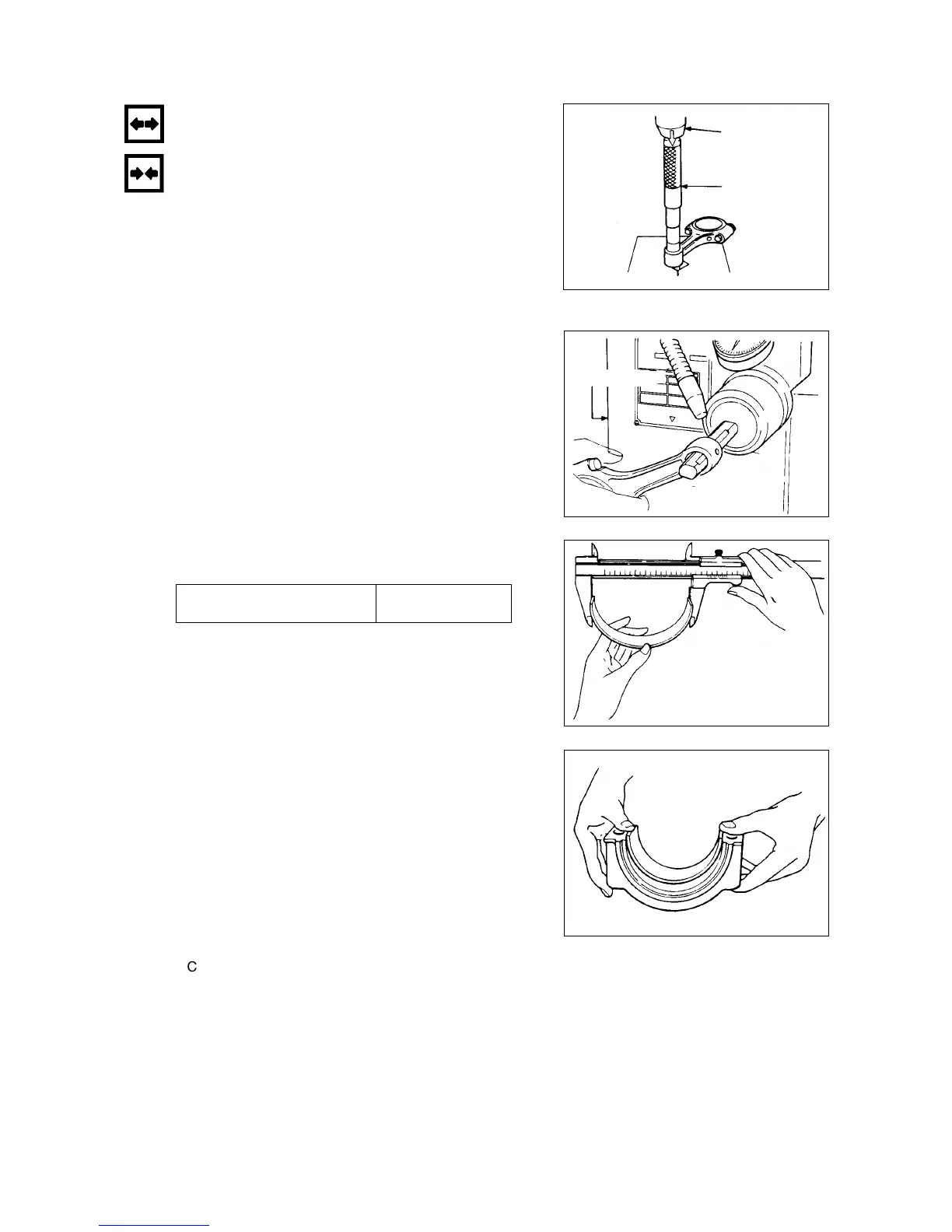

Connecting rod bearing

Bearing spread

Bearing tension

1. Fit the connecting rod bearing lower half into the

connecting rod bearing cap.

2. Check the connecting rod bearing lower half

tension.

If the tension is insufficient, the bearing must be

replaced.

3. Reassemble the connecting rod and bearing cap.

Reamer

Pin hole grinder

2.3.12. Crankshaft and Bearing

¡¡

‹

Crankshaft and bearing inspection

1. Inspect the crankshaft journal and pin surfaces for

excessive wear and damage.

2. Inspect the oil seal fitting surfaces of the crankshaft

front and rear ends for excessive wear and damage.

3. Replace or repair the crankshaft if any excessive

wear or damage is found.

4. Inspect the crankshaft oil ports for obstructions.

5. Use high pressure air to clean the oil ports if necessary.

Bench press

Brass bar

Standard (mm)

68.00¡›68.01

(2.677~2.678 in)

Loading...

Loading...