English

English: 9

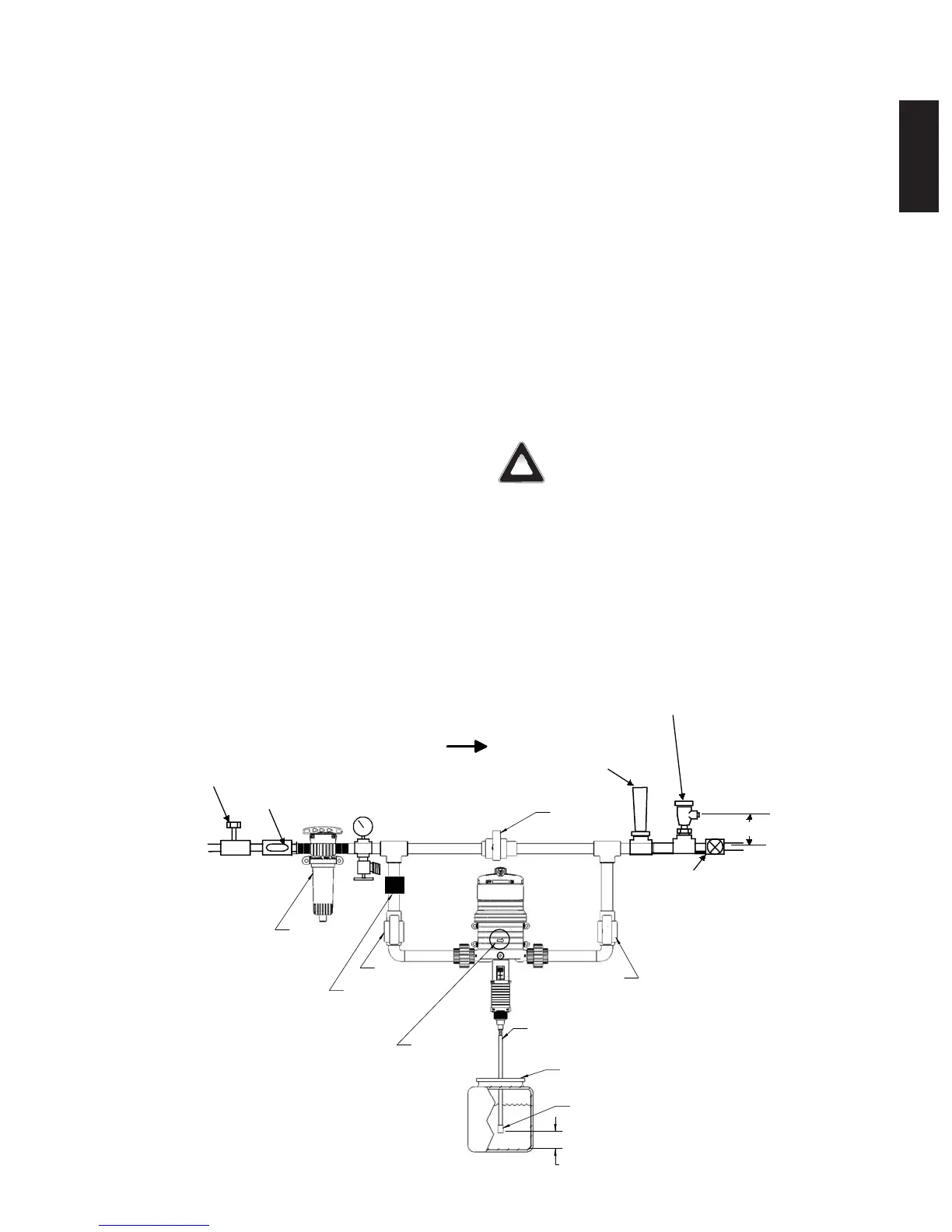

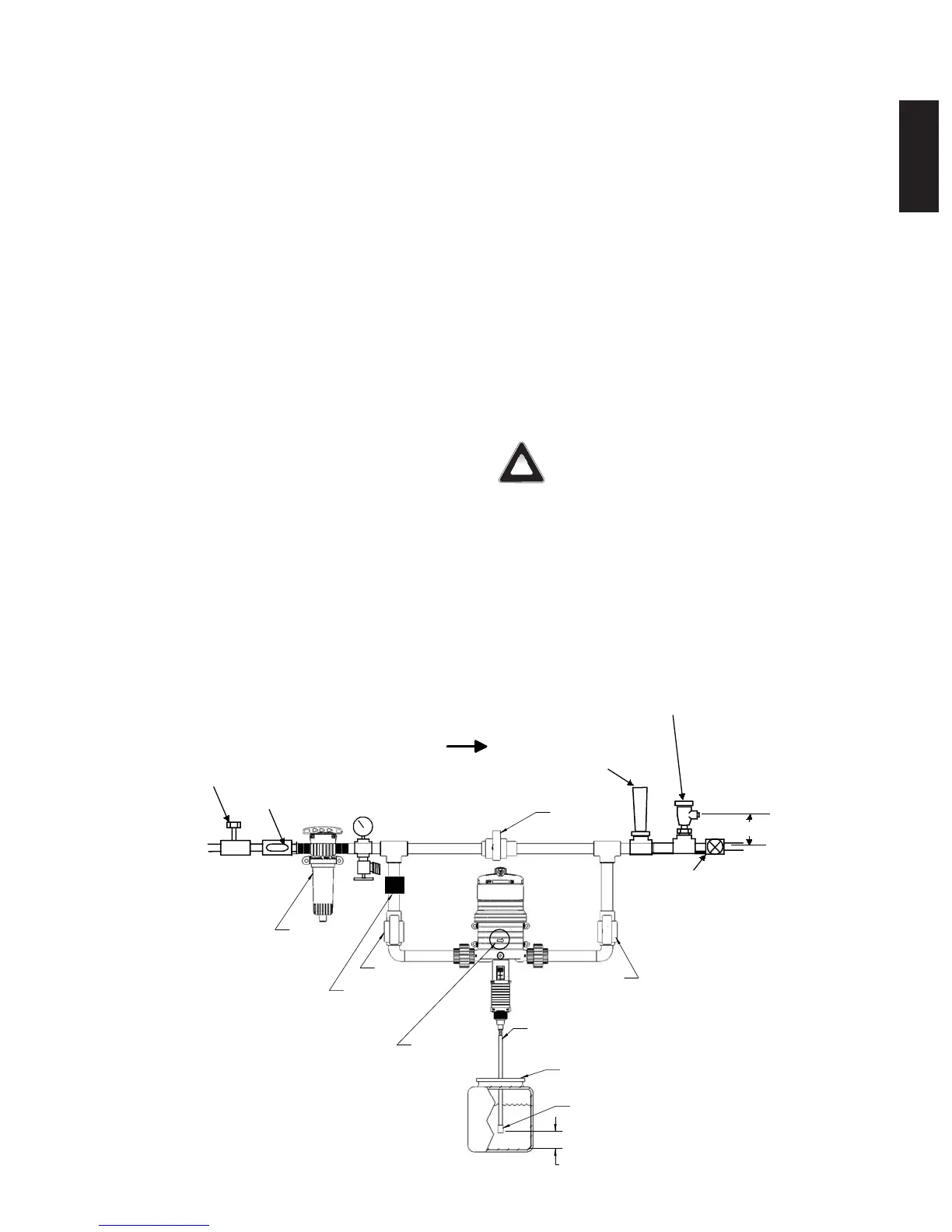

Fluid Filter (Required)

Install a fi lter of 140 mesh (104 micron) or fi ner depending

on your fl uid quality to prolong the working life of the injector

and for the warranty to be valid.

Dosmatic recommends a Twist II

Clean

®

fi lter that can be ordered with your injector.

Mounting Injector

Securely fasten your injector to a solid object such as a wall or in

a cold fl uid line. Note arrow on injector indicates fl uid fl ow.

Backfl ow Preventor (Recommended)

Install one that meets local code requirements.

Pressure Safety Release Device (Recommended)

Prevents pressure from exceeding specifi cations of the unit.

Bypass Valve Set-up (Recommended)

Allows the injector to be taken off-line for maintenance

or storage when not in use.

Fluid-Hammer Arrester (Recommended)

Prevents fl uid-hammer damage to the injector when operating

quick closing solenoid, pneumatic or hand-operated ball valves

on the fl uid system.

Anti-Siphon Valve (Optional)

To prevent solution from being siphoned out (from the solution

container) into the feed lines when the upstream valve is shut off.

The anti-siphon valve must be installed on the downstream outlet.

Additional Siphoning Prevention

Place solution container on a level below the injector suction tube

fi tting. Using the inlet side as a shut-off valve could cause full

strength solution to siphon into the feed line.

Solution Container

Use any size container. A lid or cover is recommended. To connect

your solution container, gently push the end of the suction tube

onto the bottom of the suction tube fi tting assembly.

Place the fi lter into the solution container at least 2" (5cm) from

the bottom and fi ll with at least 2" (5cm) of chemical solution.

Never Use Petroleum Based Lubricants

The injector is shipped with a thin coat of silicone around the

seals for ease-of-assembly. Petroleum based lubricants such

as Vaseline©, baby oil, WD40©, or motor oil on the O-rings or

any part of the injector should never be used as this can cause

particles to adhere and clog or damage the injector.

Check System for Leaks and Start-Up Procedures

Open the bypass valve (A), close inlet valve (B) and outlet

valve (C) to prevent fl uid fl ow into the injector. SLOWLY turn on

the main fl uid line. Run fl uid fl ows between 5 -12 gpm (11-45

l/m) through the plumbing system. Open all of the valves located

downstream from your injector to release trapped air. SLOWLY

open the inlet valve (B). Open the outlet valve (C) and close valve

(A). As fl uid travels through the injector, you will hear a “clicking”

sound. Check for leaks and correct if necessary.

COVERED CONTAINER

INLET FILTER

INLET VALVE

(RECOMMENDED)

BYPASS VALVE

(RECOMMENDED)

OUTLET VALVE

(RECOMMENDED)

SUCTION TUBE

SOLUTION FILTER

50 MM

2" REQUIRED

(A)

(B)

(C)

FLOW INDICATOR

BACK FLOW

PREVENTOR

BYPASS

DIRECTION OF FLOW

140 MESH / 104 MICRON

(MINIMUM REQUIRED)

FLOW CONTROL

VALVE @ OUTLET

ANTI-SIPHON

VALVE

(OPTIONAL)

(OPTIONAL)

FLUID HAMMER

ARRESTER

PRESSURE

REGULATOR

(RECOMMENDED)

(RECOMMENDED)

PRESSURE

GAUGE

(OPTIONAL)

(OPTIONAL)

FILL

VALVE

(OPTIONAL)

6" minimum

152.4 mm

PRESSURE SAFETY

DEVICE

(RECOMMENDED)

Installation and Start-up

Fig. 5

Refer to Fig. 4 and Fig. 5

Suggested Installation Diagram

!

Loading...

Loading...