Calibration

Dräger Polytron 8000 15

5 Calibration

Repeat the calibration of the device at regular intervals as

specified in the respective sensor data sheet.

5.1 Calibrating the device

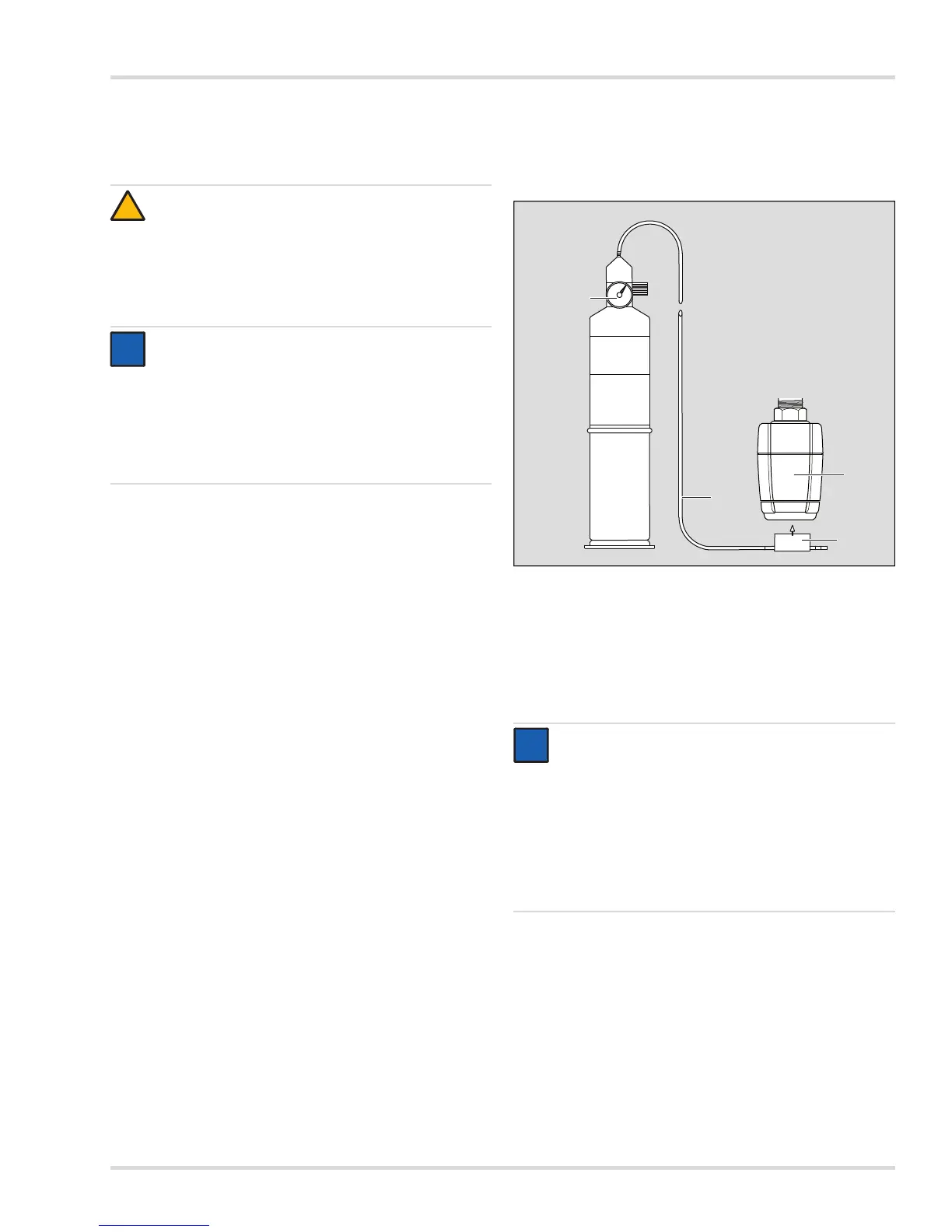

1. Connect the pressure regulator to the test gas cylinder.

2. Attach the calibration adapter to the sensor.

3. The gas flow should be approx. 0.5 L/min.

4. Connect the tube to the calibration adapter.

1 Pressure regulator

2 EC sensing head

3 Calibration adapter

4Tube

5 Test gas cylinder

5.1.1 Zero point calibration

1. Select Calibration > Zero Calibration and confirm.

The Maintenance signal is transmitted.

The message Apply zero gas appears.

2. Apply zero gas (synthetic air or nitrogen) to the sensor.

3. Select Next and confirm.

The current measured value is displayed.

CAUTION

Danger to health! Do not inhale the test gas.

Observe the hazard information in the corresponding

safety data sheets. Provide venting into a fume hood

or outside the building.

Always calibrate the zero point first before the sensitivity.

Otherwise the calibration will be faulty!

NOTICE

Calibration is not possible if the date and time are not

set (see chapter 8.2.3 on page 20).

Dräger recommends calibrating devices with target gas.

This method of target gas calibration is more accurate

than a surrogate gas calibration. A surrogate gas

calibration may only be performed as an alternative if

a target gas calibration is not possible.

NOTICE

Ambient air can also be used instead of nitrogen or

synthetic air to zero the sensor, provided it is insured

that the ambient air contains no target gas or any other

gas for which the sensor may be cross-sensitive to

(see the details in the sensor data sheet). In this case,

neither a test gas cylinder nor a calibration adapter is

required for the zero point calibration.

The zero point cannot be calibrated for the O

2

sensor

and exclusively Nitrogen must be used for testing.

Loading...

Loading...