9 | Maintenance

D-LX 201/721

91

9.4 Maintenance work

● Check the purge air unit, including the purge air hoses, for damage.

● Check the hose connections for leak-tightness and secure fitting.

● Check the lens of the flame monitor for contamination.

Remove any deposits using oil-free compressed air or a soft, lint-free cloth (lens cloth

or microfibre cloth), moistened with water and alcohol if necessary. Adjust the purge

air volume if contamination is regularly found on the outside of the lens.

NOTICE

The flame monitors (including the Ex versions and all associated components) are

devices with type approvals.

Any changes to to devices with type approvals will lead to the loss of the approval.

Repairs must only be performed by the manufacturer or persons that it has authorised

to do so. This is the only way of ensuring responsible compliance with the

specifications for the type approval of the certifying body.

9.5 Fault

If a fault is detected in the safety-relevant software and hardware components during

the internal self-monitoring of the flame monitor, an error shutdown with internal fault

locking will be triggered. The relays for the flame notification and the ready for opera-

tion notification will be deactivated, and the red fault LED on the back of the housing

will light up permanently. The yellow "Power" LED starts to flash.

The number of times that the yellow LED flashes allows the commissioning engineer/

operator to perform a more accurate analysis of the cause of the fault. The following

fault causes are signalled:

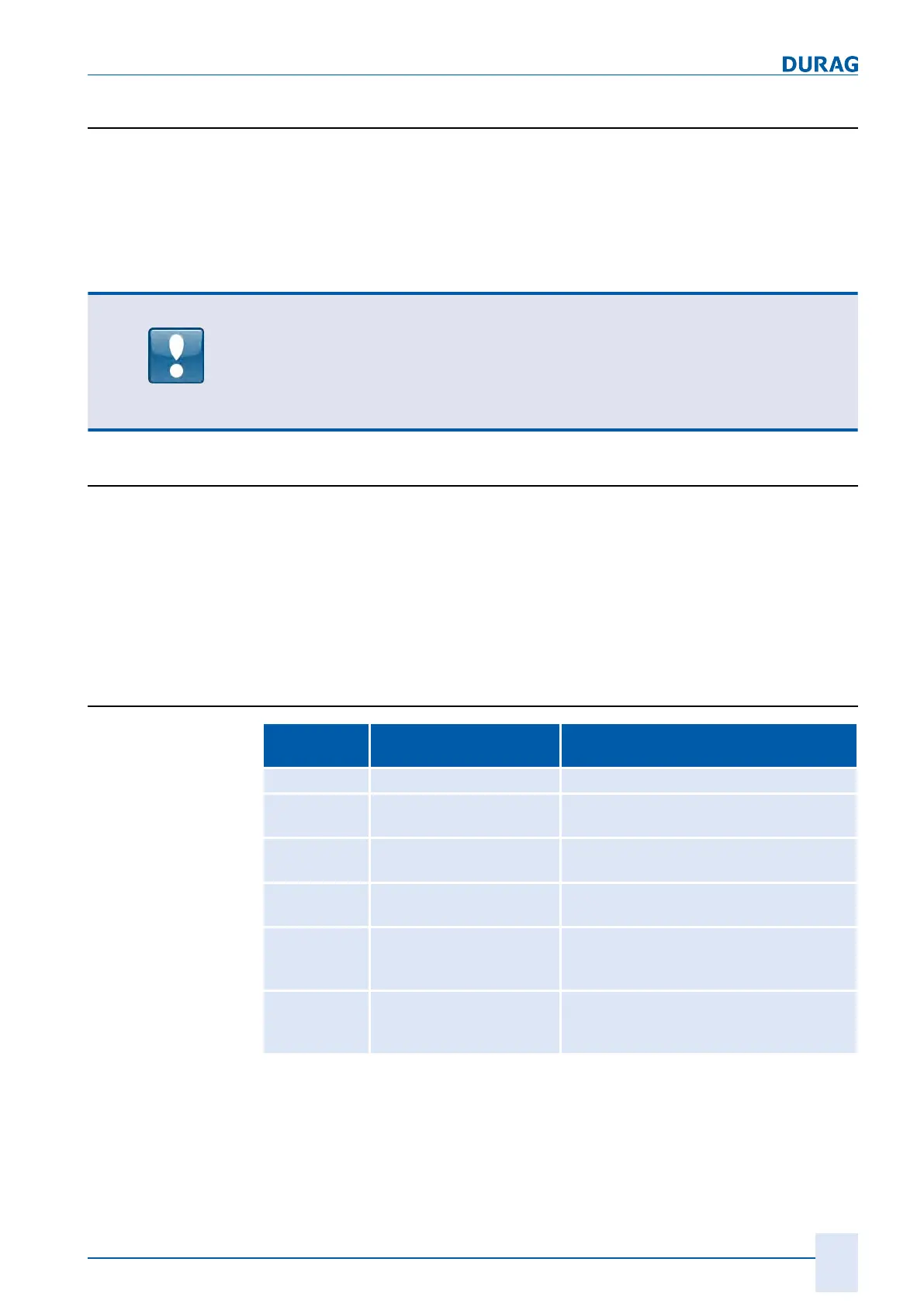

9.5.1 Fault messages

Yellow LED

flashing

Cause Possible action

1 x Synchronisation

2 x DIP switch difference Check the switch settings; correct if differ-

ent

3 x Switch difference of rotary

switch for range A

Check the switch settings; correct if differ-

ent

4 x Switch difference of rotary

switch for range B

Check the switch settings; correct if differ-

ent

5, 6, 7 x Fault in the analogue sec-

tion or extremely turbulent

flame

Check the flame quality and correct the

burner settings if necessary

8 x or more internal fault Make a note of the number of flashes;

contact DURAG Service; on-site repair

probably not possible.

Table9.1: Fault messages

Pressing the reset button on the back of the front panel acknowledges a device fault

and usually allows the flame monitor function to continue following a restart. When the

reset button is pressed, all LEDs will go out. A reset can also be performed by briefly

Loading...

Loading...