Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

Model 360/361 Control Valves

P-360M1019A

14

Operation, Parts, and Instruction Manual

LAPPING (Continued)

Special Tools Required:

• Soft felt marker

• Two wrenches that will slide over the valve stem (Key 5)

• 400 – 600 grit (fi ne grit) Loctite® Clover® compound (Key D)

Lapping Procedure

1 Install the used seat ring gasket (Key 12) into the valve

body (Key 1).

2 Install the seat ring (Key 15). Mark the position of seat

ring using the marker.

3 Install the cage (Key 19). Mark the position of cage using

the marker.

4 Do not install any plug seals into the valve plug (Key 3).

Apply fi ne grit Clover® compound to the seating surface of

the valve plug. Install the valve plug / stem assembly

(Keys 3, 4, 5) into the valve. Mark the position of the

plug / stem assembly using the marker.

5 Install used bonnet gaskets (Keys 20, 21, & 22).

6 Carefully lift the bonnet (Key 26) into place and secure the

bonnet using half of the bonnet nuts (Key 28). Mark the

position of the valve plug (Key 3) on the bonnet (Key 26)

using the marker.

7 Install the packing follower (Key 35).

8 Install the jam nut (Key 42) on to the valve stem (Key 5)

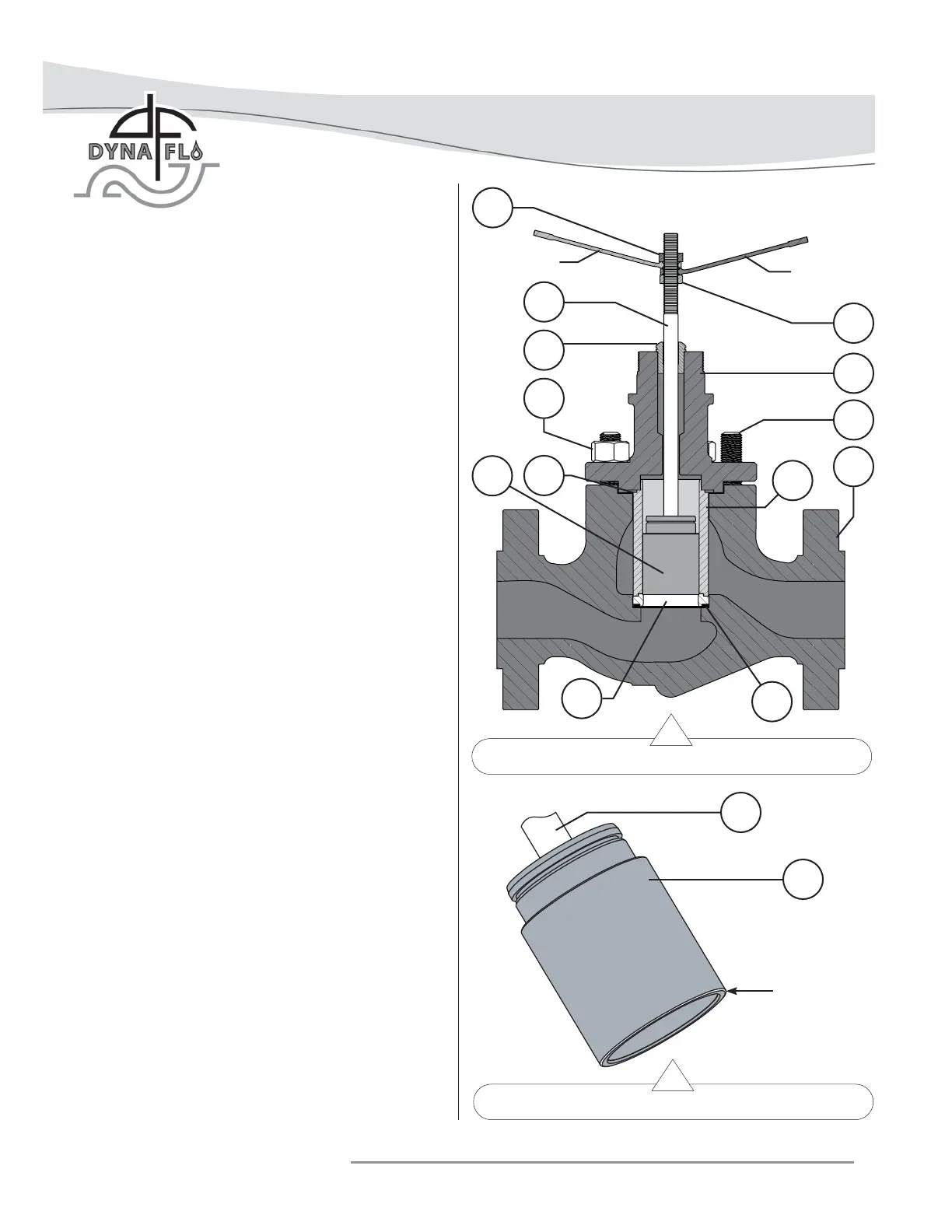

and build a handle as shown in Figure 14 and 16

using the two wrenches and the hex nut (Key 43).

9 Rotate the valve plug (Key 3) back and forth about

a quarter of a full rotation (only a small amount of

movement is required, do not make full rotations)

over the seat ring (Key 15) using the wrench handles.

10 If a seat leak test is to be performed after lapping to test

valve shut off, disassemble the lapping setup after a few

cycles of back and forth plug movement. Replace the used

gaskets (Keys 12, 20, 21, & 22) with new gaskets and

reassemble the valve for testing. NOTE: Another set of

new gaskets will need to be used for the fi nal valve

assembly if the lapping procedure needs to be repeated

after seat leak testing.

Figure 14 Lapping Procedure Setup (Steps 1 - 8)

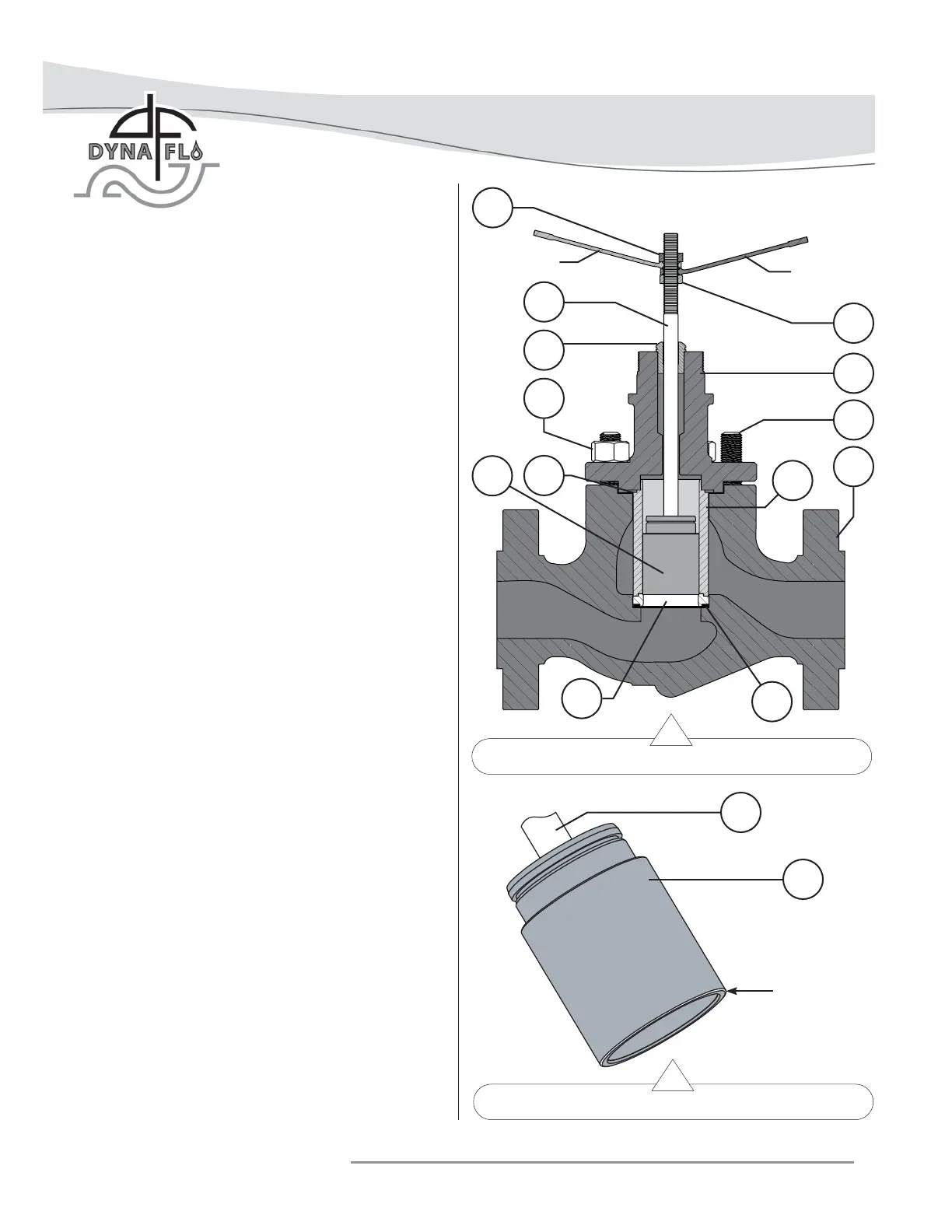

Figure 15 Lapping Compound Application

42

35

26

5

43

28

2

1

20

19

3

12

15

WRENCH

WRENCH

5

3

APPLY FINE

GRIT CLOVER®

COMPOUND

(KEY D) TO

THE SEATING

SURFACE OF

THE PLUG

Loading...

Loading...