Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

Model 360/361 Control Valves

P-360M1019A

20

Operation, Parts, and Instruction Manual

ASSEMBLY (Continued)

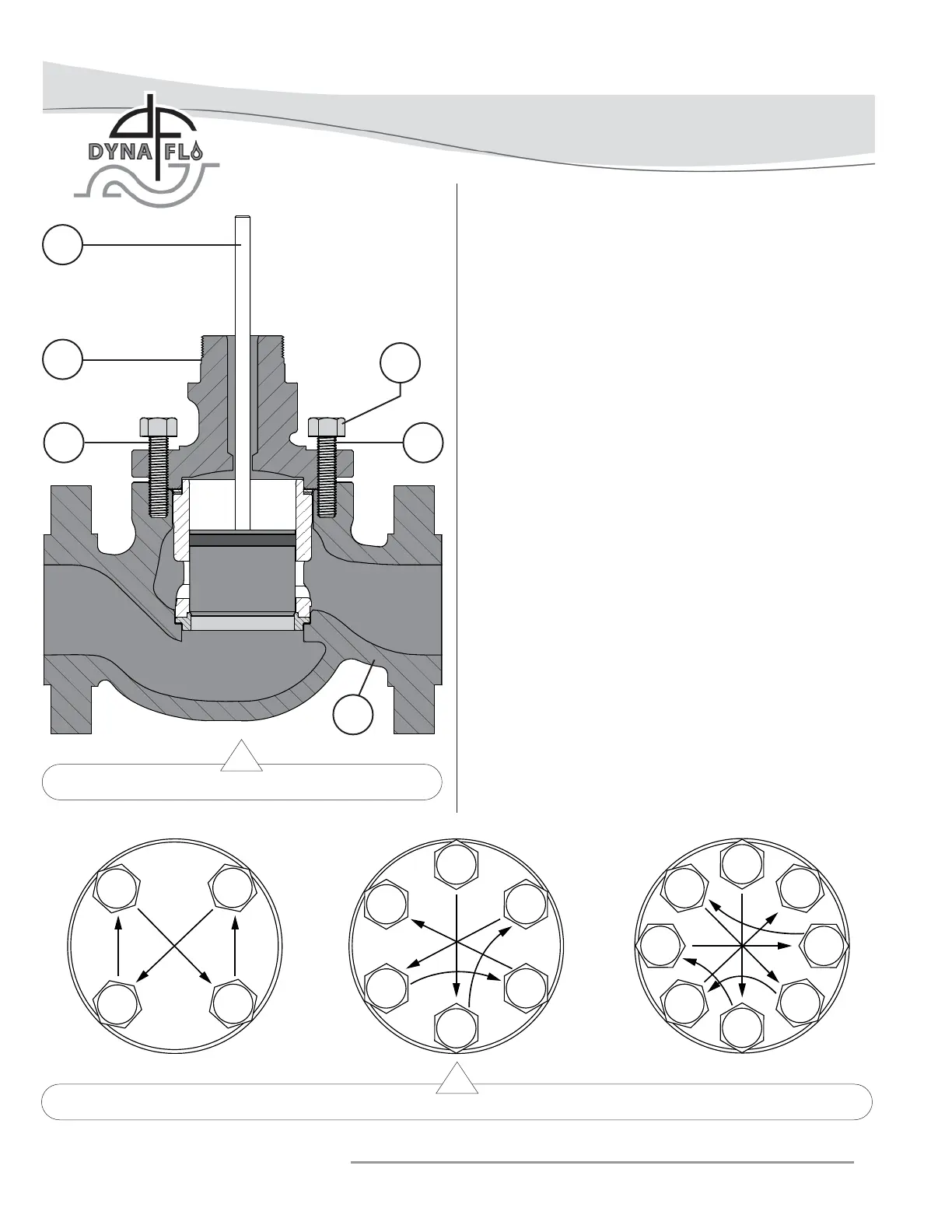

BONNET INSTALLATION (Continued)

1 Apply nickel anti-seize (Key A) to the gasket sealing

surface of the valve bonnet (Key 26).

2 Lift and lower the valve bonnet (Key 26) into place over

the valve stem (Key 5). Be careful not to damage either

the stem, bonnet, or valve body (Key 1).

3 Apply nickel anti-seize (Key A) to the threads of the

bonnet studs (Key 2). Thread the bonnet nuts (Key 28)

onto the bonnet studs until hand tight.

4 Stroke the valve a few times to center the valve trim.

5 It may help to install the packing follower (Key 22) during

bonnet installation to act as a visual cue to indicate areas

of over or under tightening. If the packing follower begins

to bind or appear lop-sided, this is an indication that

torquing procedures in Steps 6 & 7 need to be altered to

correct areas that need more tightening or less. The

packing follower should remain centered during the

torquing process.

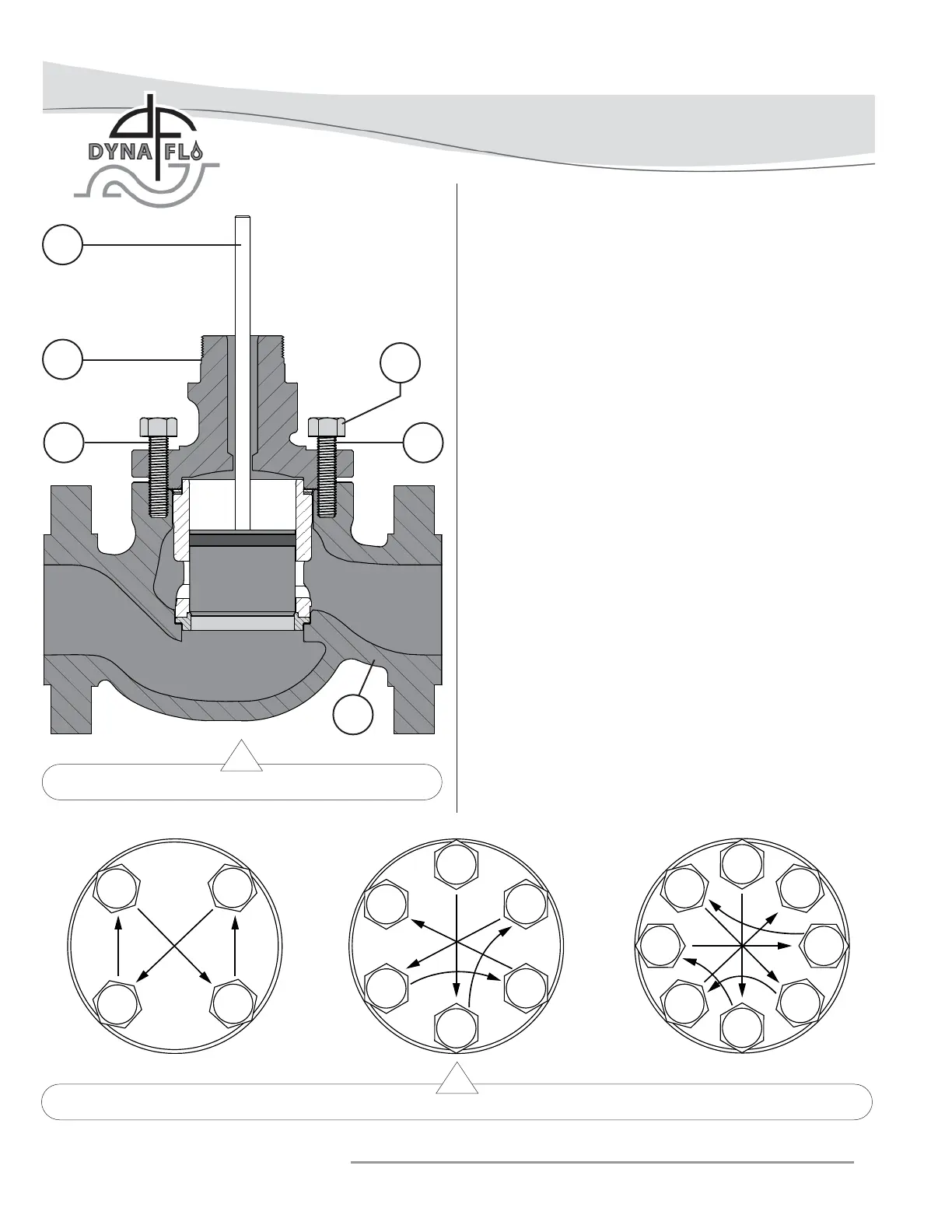

6 Follow proper body-to-bonnet bolting procedures. Begin to

torque the bonnet nuts (Key 28) ¼ (25%) of the torque

value listed in Table 5, torque the nuts in a crisscross

pattern as shown in Figure 25. Hot torquing the valve nuts

is not recommended.

7 Continue tightening the bonnet nuts (Key 28), increasing

the torque by ¼ (25%) of the fi nal torque specifi cation

each round of tightening while repeating the crisscross

pattern until the fi nal torque specifi cation is reached.

8 Double check the tightness of all nuts by torquing the

nuts to the fi nal torque specifi cation one more time after

the fi nal torque value was reached.

Figure 24 Bonnet Installation

1

2

3

4

1

2

3

4

5

6

1

2

34

5

6

7

8

Figure 25 Bolt Tightening Pattern Diagram

SAMPLE BOLT CONFIGURATION

2 A

5

28

26

1

Loading...

Loading...