Model 360/361 Control Valves

Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

P-360M1019A

13

Operation, Parts, and Instruction Manual

DISASSEMBLY (Continued)

PLUG SEAL REMOVAL (Continued)

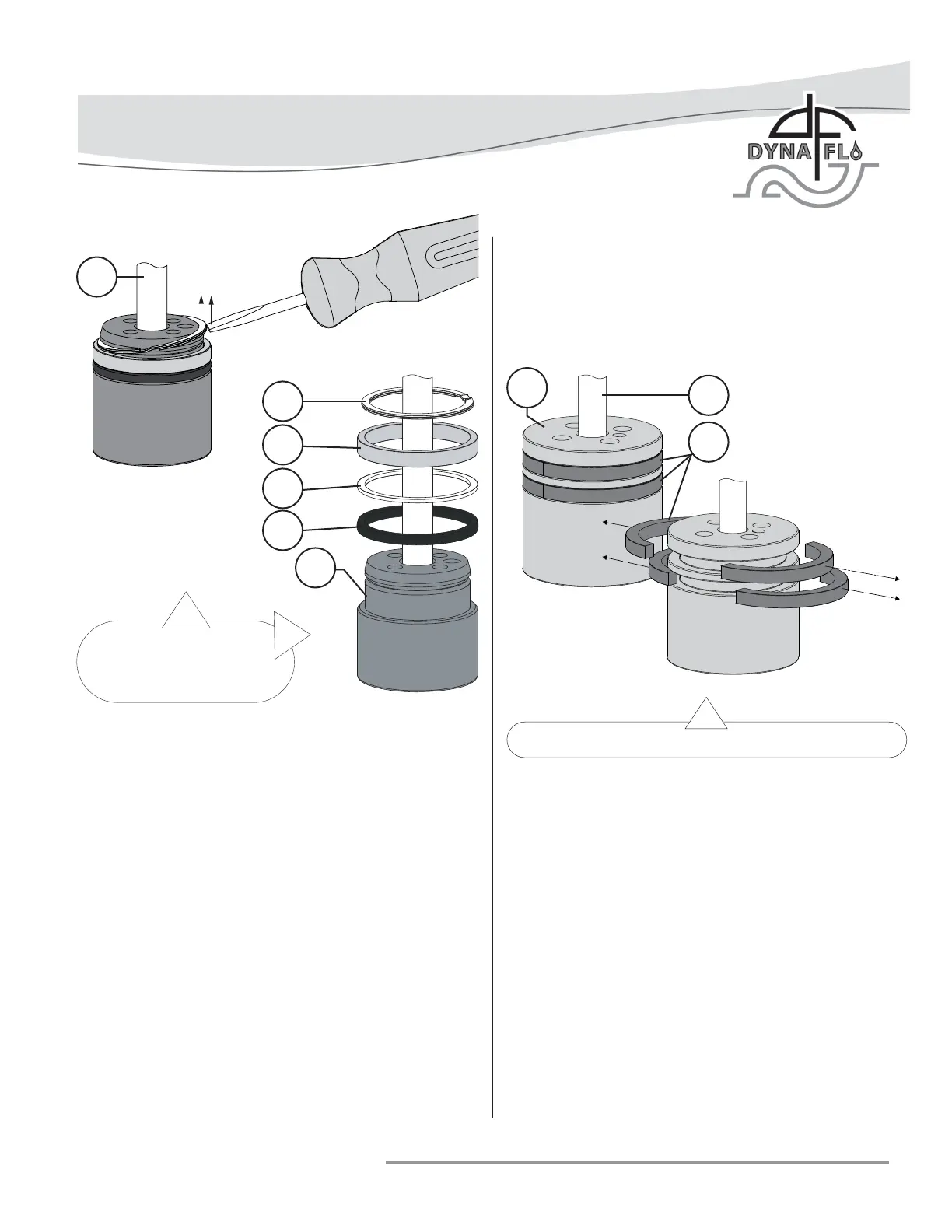

For Model 360 Three-Piece Plug Seal Ring Assemblies

with Anti-Extrusion Rings:

1 Carefully remove the retaining ring (Key 10) from the plug,

a pick set or fl at screw driver may be required to pry the

spiral rings of the retaining ring apart to assist removal.

Refer to Figure 12.

2 Remove the backup ring (Key 9).

3 Remove the anti-extrusion ring (Key 11). The anti-

extrusion ring is only included in valve assemblies rated

for over 450°F (232°C).

4 Remove the seal ring (Key 8).

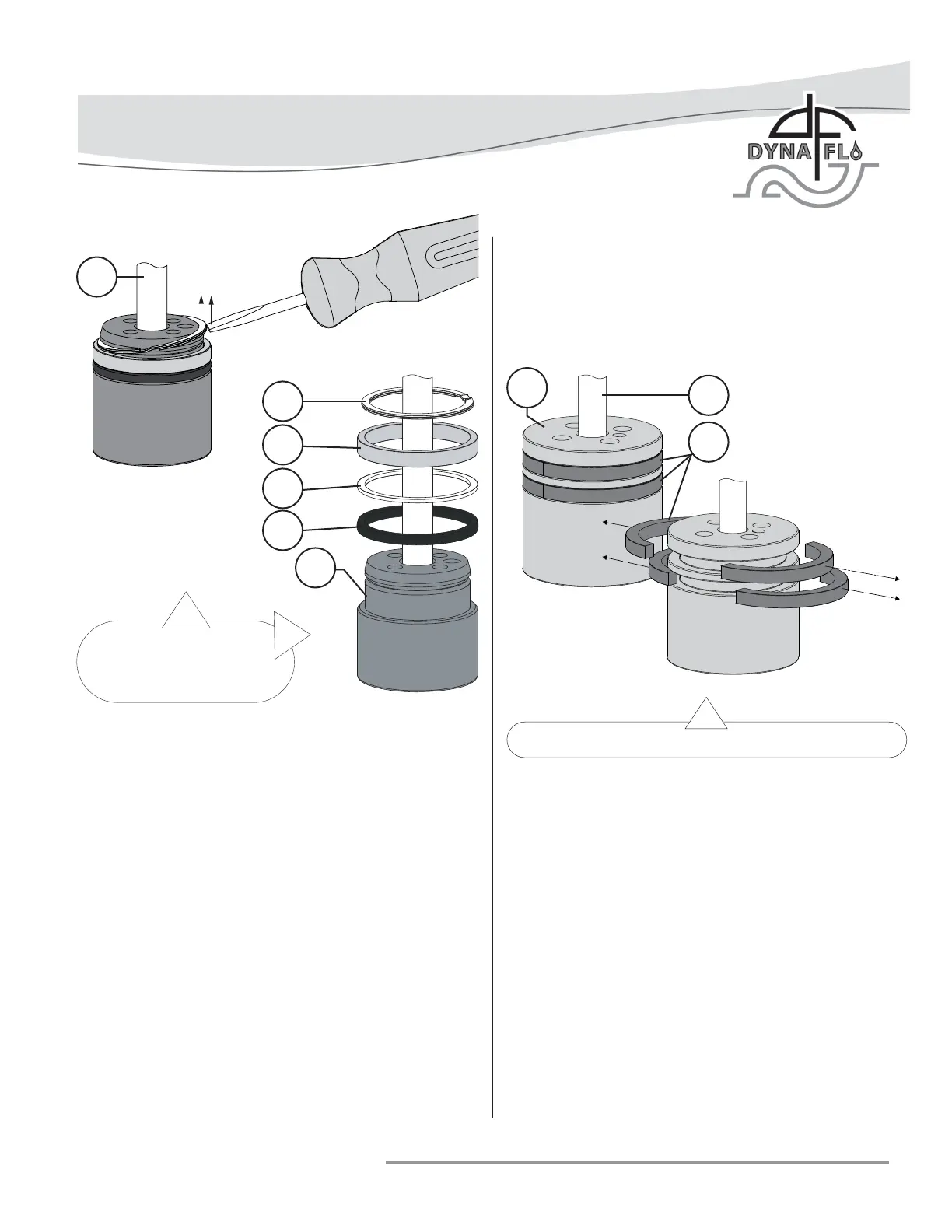

For Model 361 Valves (Refer to Figure 13):

1 Remove the piston rings (Key 48). NOTE: Piston rings are

broken in half and can be easily pulled apart.

Figure 12

Three-Piece Plug Seal

Removal (Model 360 Only)

For All Models:

Clean and inspect all parts for damage, especially the stem

(Key 5) and plug (Key 3) surfaces. Minor scratches can be

buffed or lapped out, major scratches (scratches that will stop

a fi nger nail) will need to be machined or replaced. Replace all

damaged parts and soft parts with new parts.

Figure 13 Model 361 Piston Ring Removal

LAPPING

Expect a certain amount of leakage in valves with metal

seats. In some cases where leakage has become excessive,

lapping can improve sealing performance. Before performing

the lapping process, insure all trim parts have been thoroughly

cleaned and are free of debris. Do not lap soft seat valves.

NOTE: Spiral wound gaskets (Key 20) make their seal by being

crushed and cannot be reused, this includes gaskets required to

be used during the lapping process. It may be desirable to use

an already crushed gasket in the lapping process to be replaced

with new gaskets during reassembly.

CAUTION: Once lapping has been performed with a previously

crushed gasket, it is important to mark the position and

alignment of all trim parts (Keys 3, 15, and 19) before

removal and reassembly. If trim parts are reassembled out of

their lapped alignment excessive leakage may result.

10

9

8

3

5

11*

*Only included in valve

assemblies rated over

450°F (232°C).

5

48

3

Loading...

Loading...