Model 360/361 Control Valves

Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

P-360M1019A

5

Operation, Parts, and Instruction Manual

UNPACKING VALVE FROM SHIPPING

CONTAINER

Special Tools Required:

• Properly Rated Lifting Straps (2 – 4 Straps) refer to Table 4

for actuator weights.

• Lifting Device (Example: Crane)

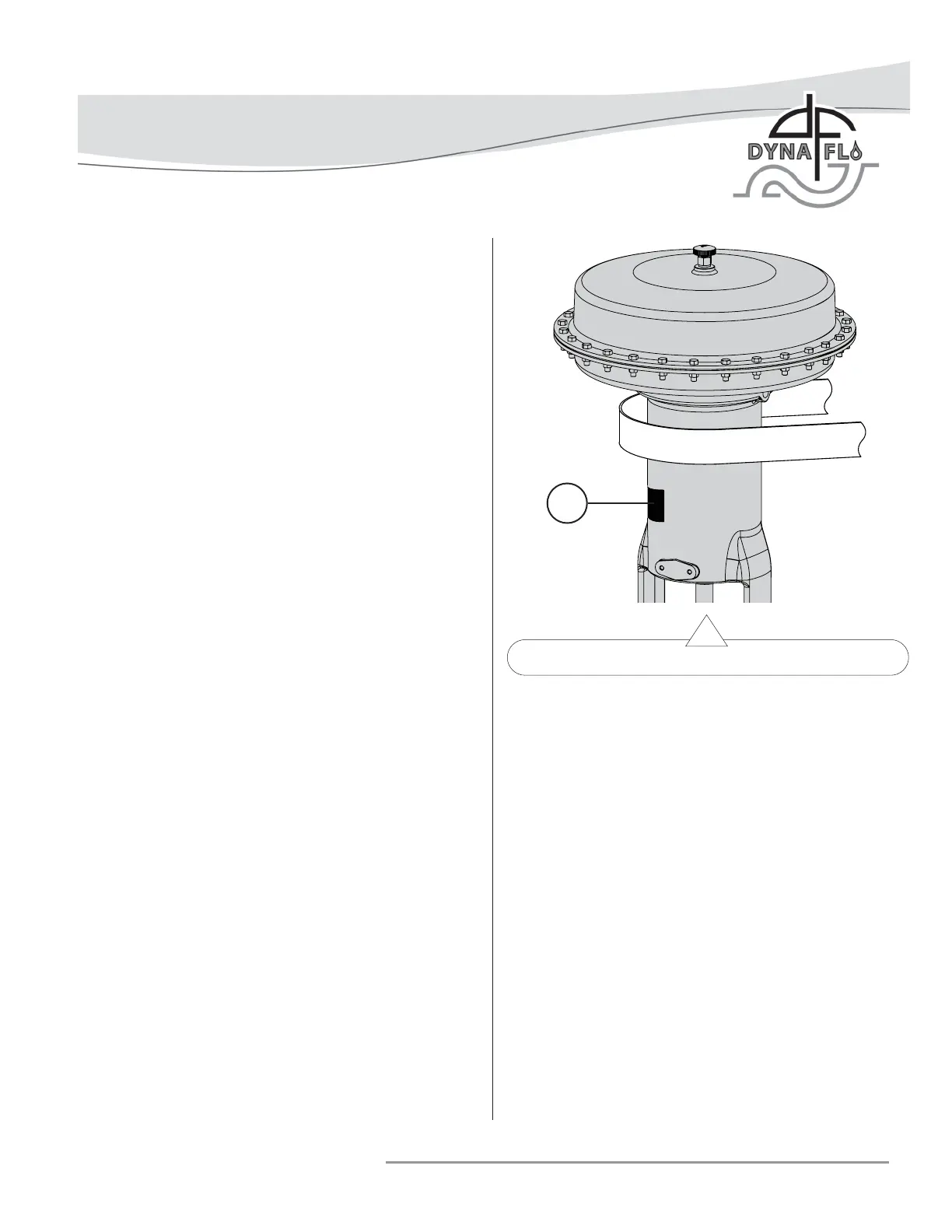

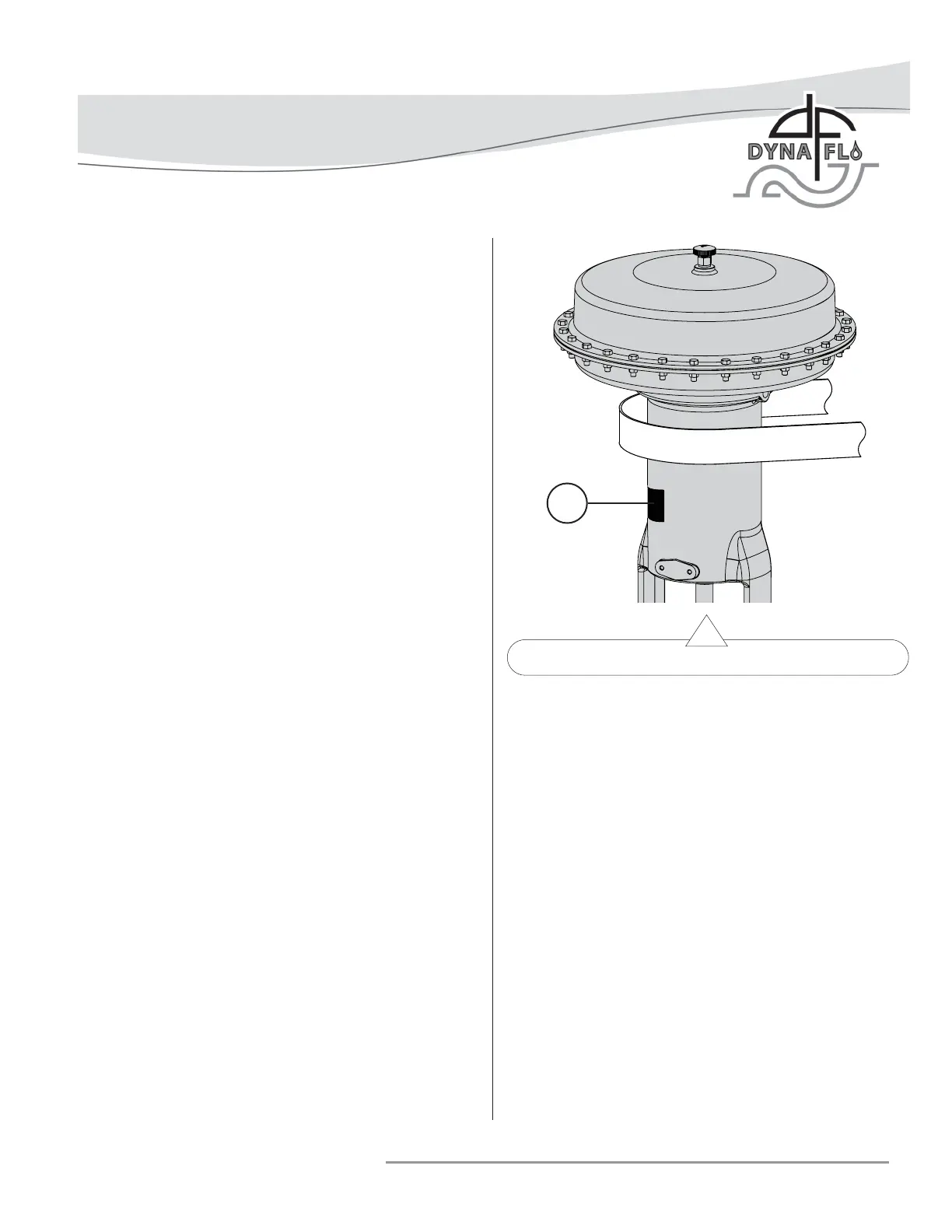

Check the packing list, verify that the list includes all the

materials in the shipping container before unpacking. Valve

information can be found on the nameplate (Key 47). Refer to

Figure 2 for nameplate location.

When lifting the valve from shipping container, place properly

rated lifting straps securely around the neck of the actuator,

refer to Figure 2 for strap placement. Straps should be placed

to avoid damage to tubing and other mounted accessories.

For valve assemblies without an attached actuator, use caution

when lifting or positioning straps so as not to damage the valve

stem.

Lift the valve/actuator assembly using proper lifting techniques.

INSTALLATION

Before You Begin:

• Read the General and Scope section of this manual (Page 2).

• Read Safety Caution (Page 2).

• Sudden movement of actuator can cause damage or injury.

It helps to have the actuator de-energized.

• Use safe work practices and lock out procedures before

placing valve in-line.

NOTE: For butt weld valve bodies, depending on the body

material, post-weld heat treatment might be required. Soft

parts, seals, some metal trim, threading and shrink-fi t parts

can be damaged by post-weld heat treatment. If post-weld heat

treatment is required, it is recommended that all internal valve

parts be removed from the valve body. Contact Dyna-Flo for

more information.

Parts Required:

• Appropriate Line Flange Nuts and Bolts

• Appropriate Line Flange Gaskets

• If the valve has small internal fl ow passages such as

Anti-Cavitation or Low-Noise trim, the installation of an

upstream strainer should be considered to prevent clogging

of these small passages.

Figure 2 Actuator Lifting Suggestions

Installation Steps:

1 Check the packing box bolting (Key 38) for proper

tightness. Refer to Packing Installation on Page 20 for

proper packing tightening instructions.

2 The valve assembly may be installed in any position

unless limited by vibration considerations, it is however

recommended that the valve be installed with the valve

stem (Key 5) perpendicular to the ground. NOTE: For

some non-vertical orientations, the valve actuator may

need to be supported.

3 Install the valve with fl ow through the valve in the

direction shown by the fl ow arrow on the valve body.

4 Install the appropriate line fl ange gaskets.

5 Apply Permatex

® Nickel Anti-Seize to the threads of the

fl ange studs and install.

6 When possible, before tightening the line bolting, stroke

the valve and check for smooth operation through the full

stroke. Unsteady valve stem movement could be an

indication of an internal problem.

7 Tighten the line fl ange bolting in even increments in a

crisscross pattern until the correct line bolt torque

specifi cation is reached.

LIFTING STRAP

47

Loading...

Loading...