Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

Model 360/361 Control Valves

P-360M1019A

4

Operation, Parts, and Instruction Manual

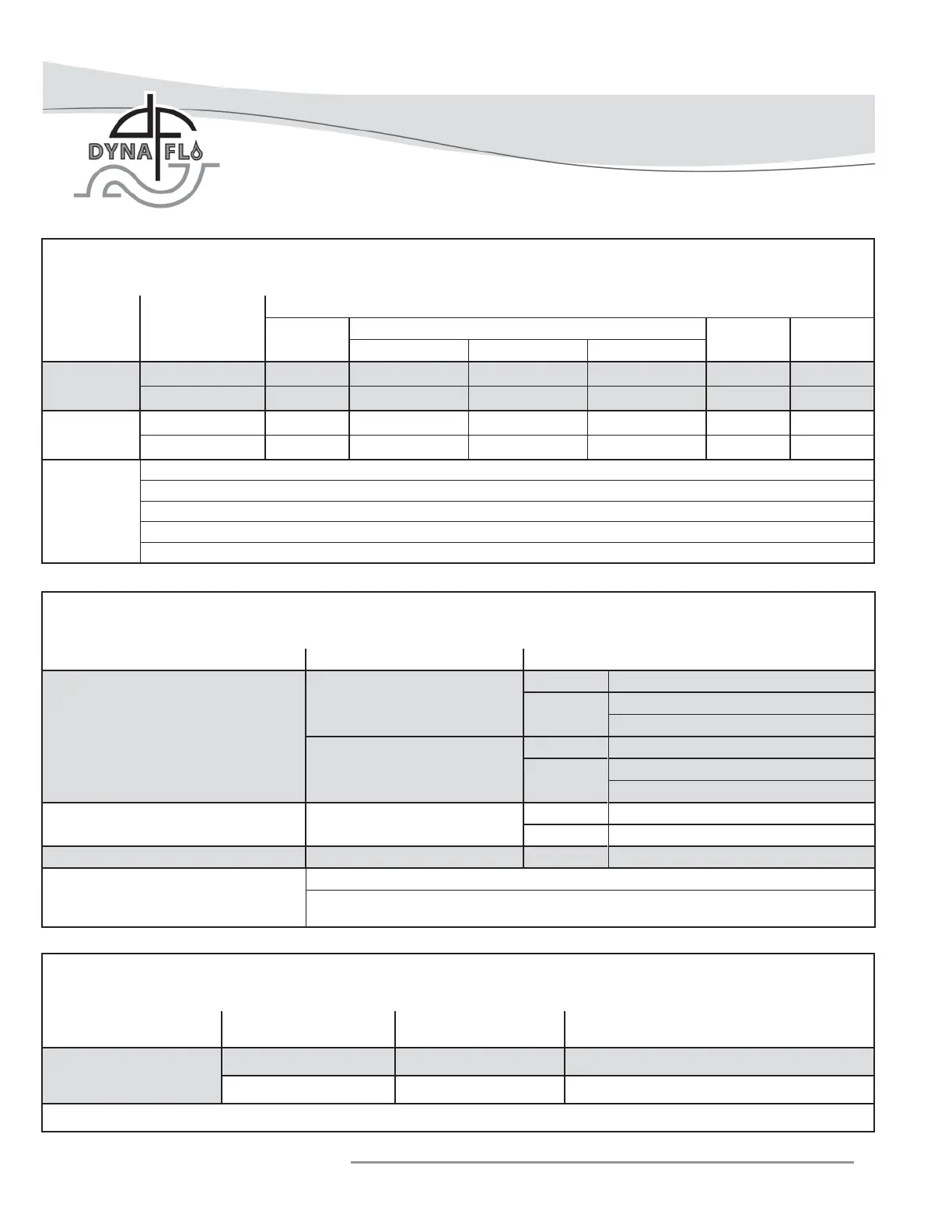

Table 2

Standard Shut-Off Classifi cations (in accordance with ANSI/FCI 70.2 and IEC 60534-4)

Valve Trim Seat Option Shut-Off Class

All

(Except Anti-Cavitation)

PTFE (Soft Seated)

Standard Class V (Air Test)

Optional

Class V

Class VI

(1)

Metal

Standard Class IV

Optional

Class V

(2)

Class VI

(1)

Anti-Cavitation 1 Stage Metal

Standard Class IV

Optional Class V

Anti-Cavitation 2 Stage Metal Standard Class V

Notes:

1 - Refer to Table 3.

2 - Class V shut-off requires a spring-loaded seal ring, radius-seat plug, and wide-bevel

seat ring. Not available with 8 inch port quick opening cages.

Table 1

Available Valve Confi gurations

Valve Model

Valve Size

Inch

End Connection

NPT

(1)

RF

(2)

and RTJ

(3)

(Flanged)

BWE

(4)

SWE

(5)

ASME Class 150 ASME Class 300 ASME Class 600

360

1 / 1-1/2 / 2

3 / 4 / 6 / 8

360A

1 & 2

3 / 4 / 6

Notes:

1 - NPT = Screwed.

2 - RF = Raised Face.

3 - RTJ = Ring Type Joint.

4 - BWE = Butt Weld (ASME Class 600 Only).

5 - SWE = Socket Weld (ASME Class 600 Only).

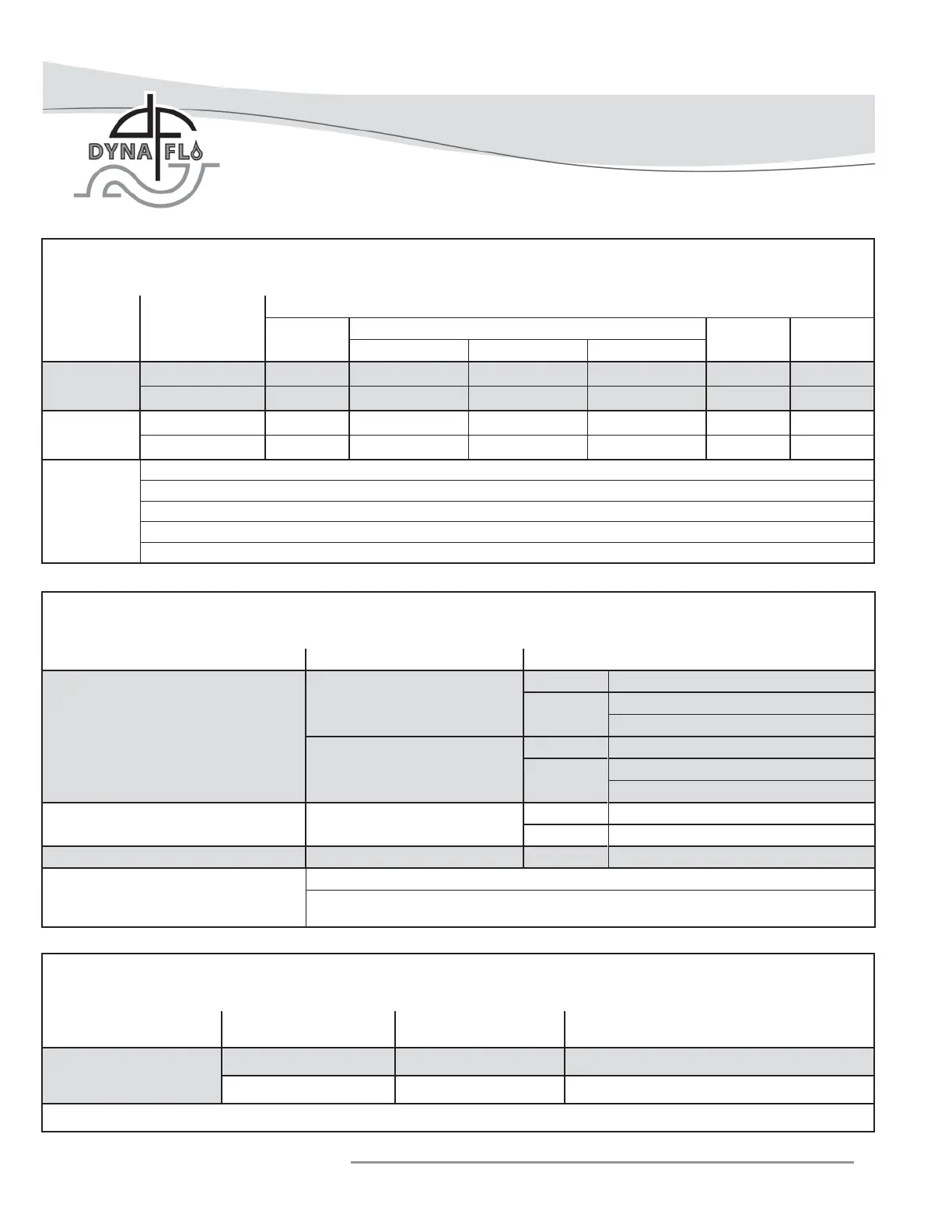

Table 3

Available Valve Confi gurations for Class VI Shut-Off (in accordance with ANSI/FCI 70.2 and IEC 60534-4)

Valve Model

Port Size

Inch

Valve Seat Minimum Seat Load

360

Refer to Table 23 for Trim

≥3.4375≤7 Metal

(1)

300 lbs./lineal inch

≥3.4375≤7 PTFE Consult Dyna-Flo

Note: 1 - Class VI shut-off requires a spring-loaded seal ring, radius-seat plug, and wide-bevel seat ring.

Loading...

Loading...