Dyna-Flo Control Valve Services Ltd.

Phone: 780 • 469 • 4000 Toll Free: 1 • 866 • 396 • 2356 Fax: 780 • 469 • 4035 Website: www.dynafl o.com

Model 360/361 Control Valves

P-360M1019A

8

Operation, Parts, and Instruction Manual

MAINTENANCE

Note: Seals, soft parts, and packing (including live loaded

packing) should all be inspected frequently for leaks, wear and

damage. Maintenance to the valve can be performed while the

valve is still in-line, the actuator must be removed to replace

packing (Refer to Page 6 for Actuator Removal instructions).

Before you begin:

• Read Safety Caution (Page 2).

• Determine if valve has standard or live loaded packing (Refer

to Figures 27, 29, 30 & 31).

• Follow Steps 1 – 6 of Before You Begin from PERIODIC

INSPECTION (Page 7).

Packing Maintenance

If the packing is leaking, proper tightening of the packing may

correct the leak. If re-tightening the packing to the proper

specifi cations does not stop the leakage it is possible that the

stem or wall of the packing box is damaged. Replace or repair

parts as necessary. For instructions on packing removal only,

refer to the Disassembly, Packing Removal section on Page 9.

1 Determine the type of packing installed in the valve. Refer

to Figures 27, 29, 30, and 31 for packing styles.

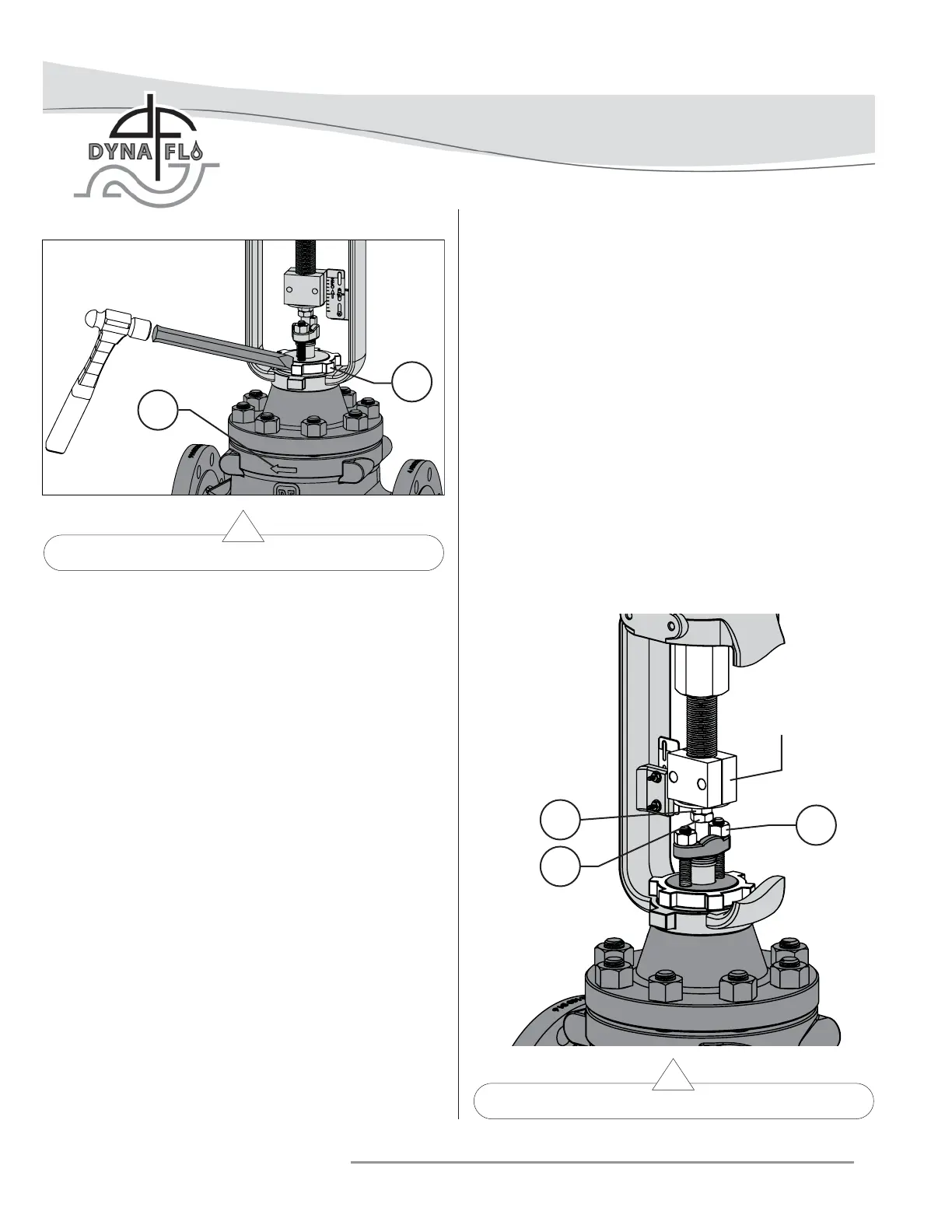

Figure 4 Yoke Nut being loosened with a Chisel

For Single PTFE V-Ring Packing (Spring-Loaded):

Tighten the packing nuts (Key 38) evenly in an alternating

pattern until the shoulder of the packing follower (Key 35)

makes contact with the top face of the bonnet (Key 26).

Proceed to tighten the packing nuts to the torque specifi cation

listed in Table 6. Refer to Figure 27.

For Double PTFE V-Ring and Graphite Packing:

Tighten the packing nuts (Key 38) evenly in an alternating

pattern to the minimum recommended torque specifi cations

listed in Table 6 on Page 30, continue tightening until

leakage stops or the maximum torque specifi cation is reached.

If leakage continues after reaching the maximum

recommended torque the packing will need to be replaced,

do not tighten the packing past the maximum recommended

torque as this will cause excessive packing friction.

For Live-Loaded Packing:

Refer to the Sliding Stem Live-Loaded Packing Manual (P-LLPS)

for proper maintenance procedures.

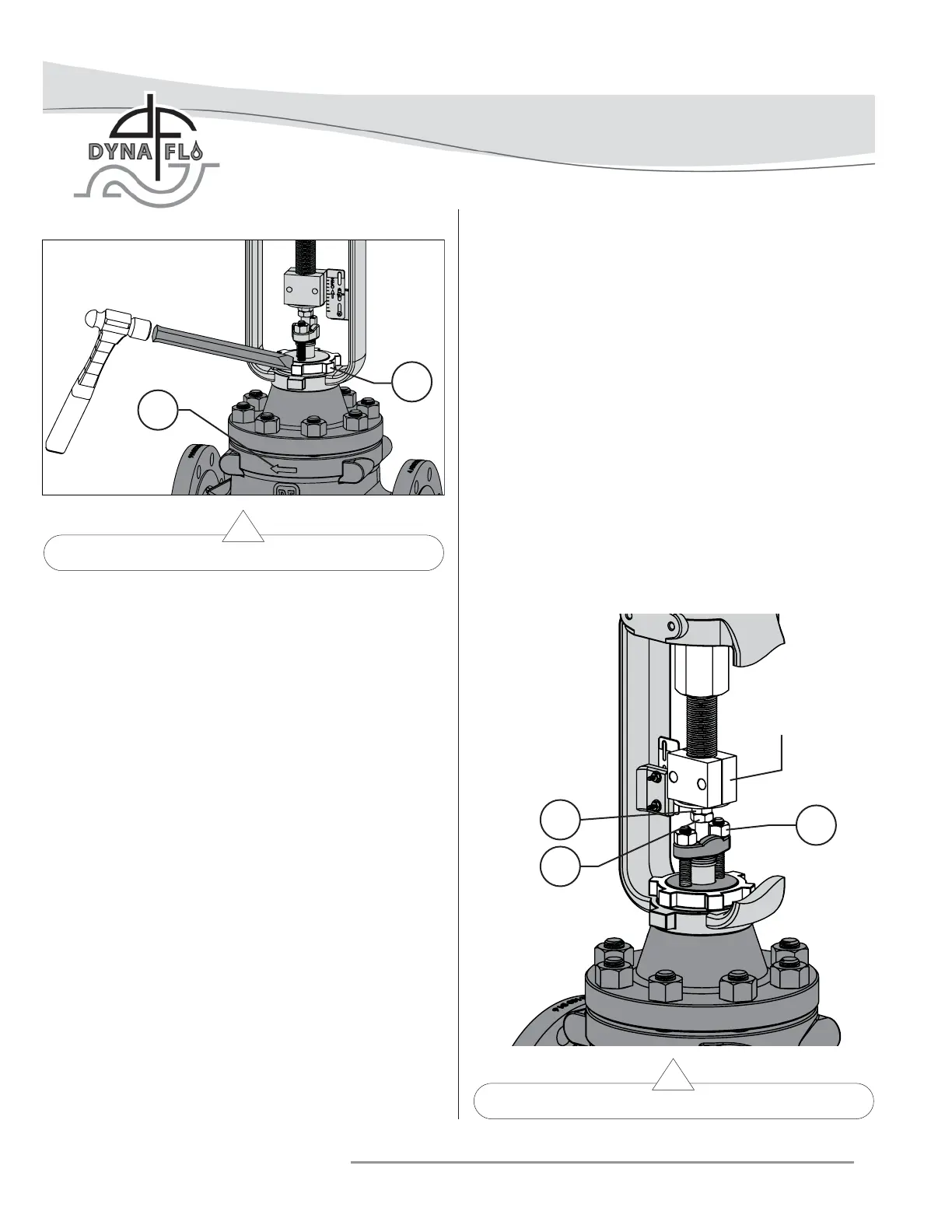

Figure 5 Packing Nut and Stem Connector Detail

44

45

38

STEM

CONNECTOR

42

43

Loading...

Loading...