During operation the various parameters of the sample analysis are shown on

the liquid crystal display, and all the stages of the process are indicated by the

L.E.D. illumination or audible warning. The principles of the operation are as

follows:-

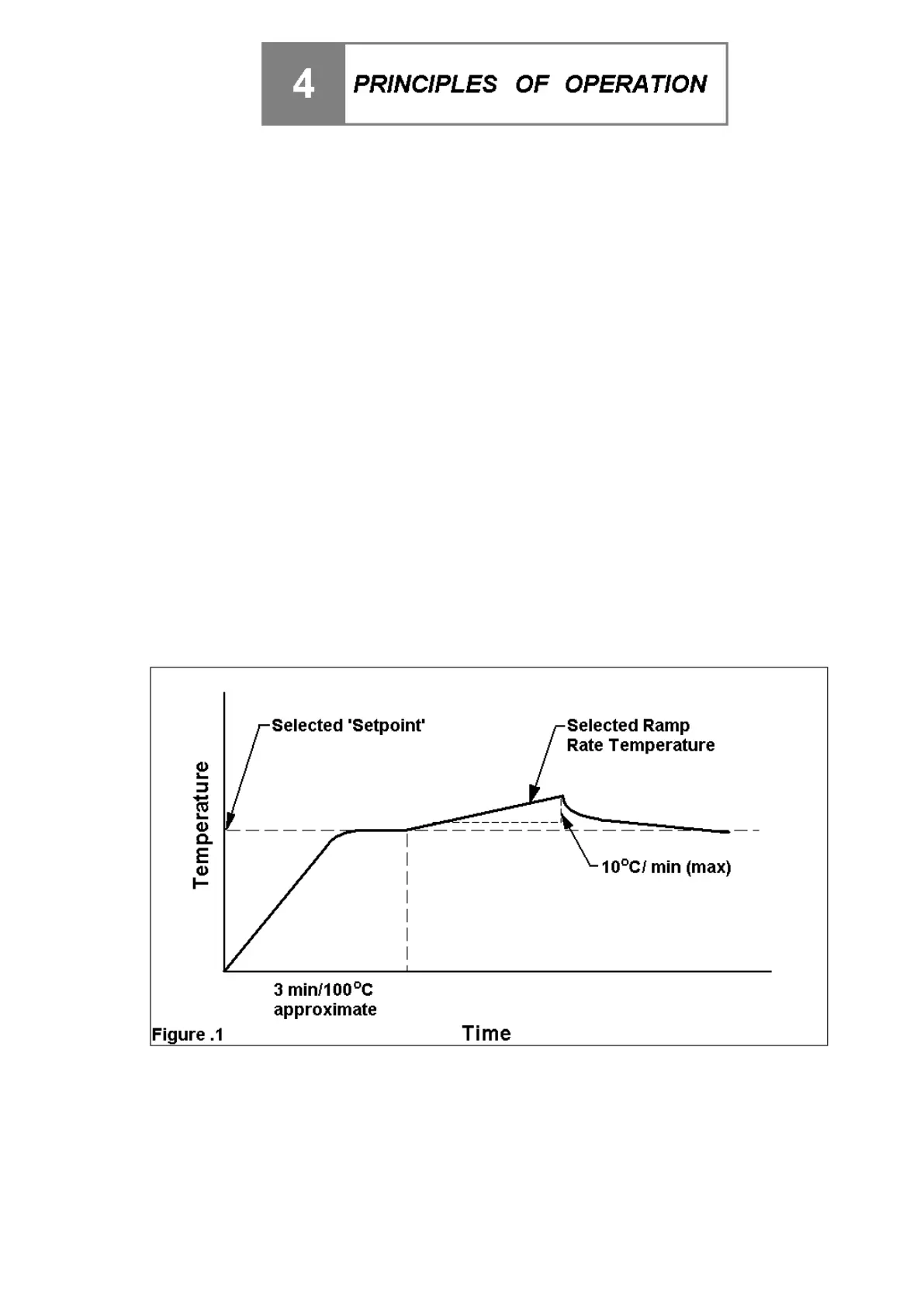

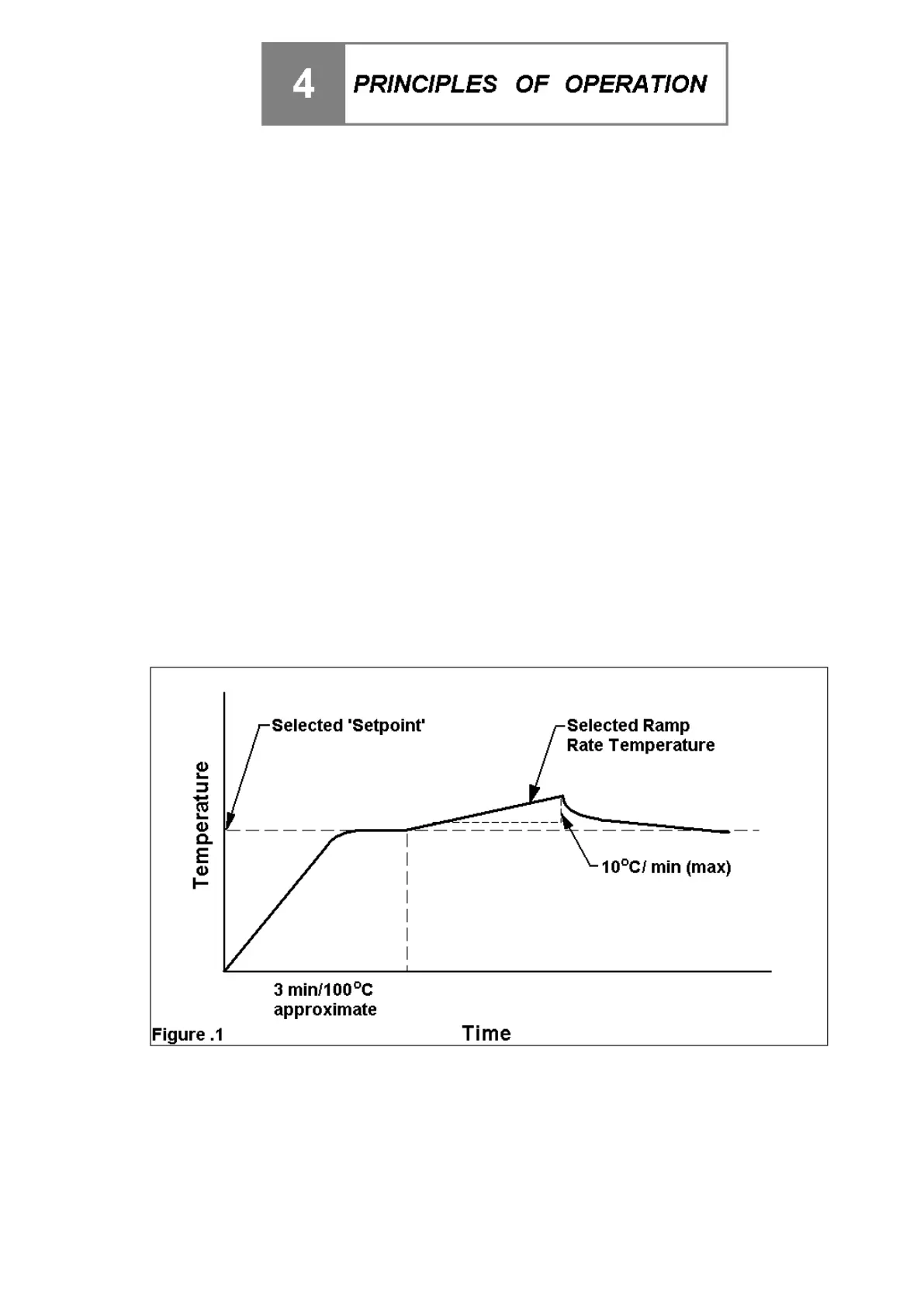

Guided by knowledge of the expected melting temperatures of the

sample, a „Set Point‟ is established and its value keyed in (see figure

1).

The oven temperature is driven to meet the „Set Point‟ at maximum

rate.

After a short delay for the over temperature to stabilise at the „Set

Point‟, the ramp is established and selected.

The temperature now increases linearly at the much slower ramp rate,

during which time the melt analysis takes place.

The melting of the sample is observed and the temperatures registered

in the memory at the appropriate time.

The temperatures (and for the IA9200 also the measuring parameters)

are now available for review on the display (and for the IA9300 & 9200

a hard copy recorded to be printed).

The oven temperature may now be directed to a new „Set Point‟ if

required for the next analysis.

Loading...

Loading...