64

English

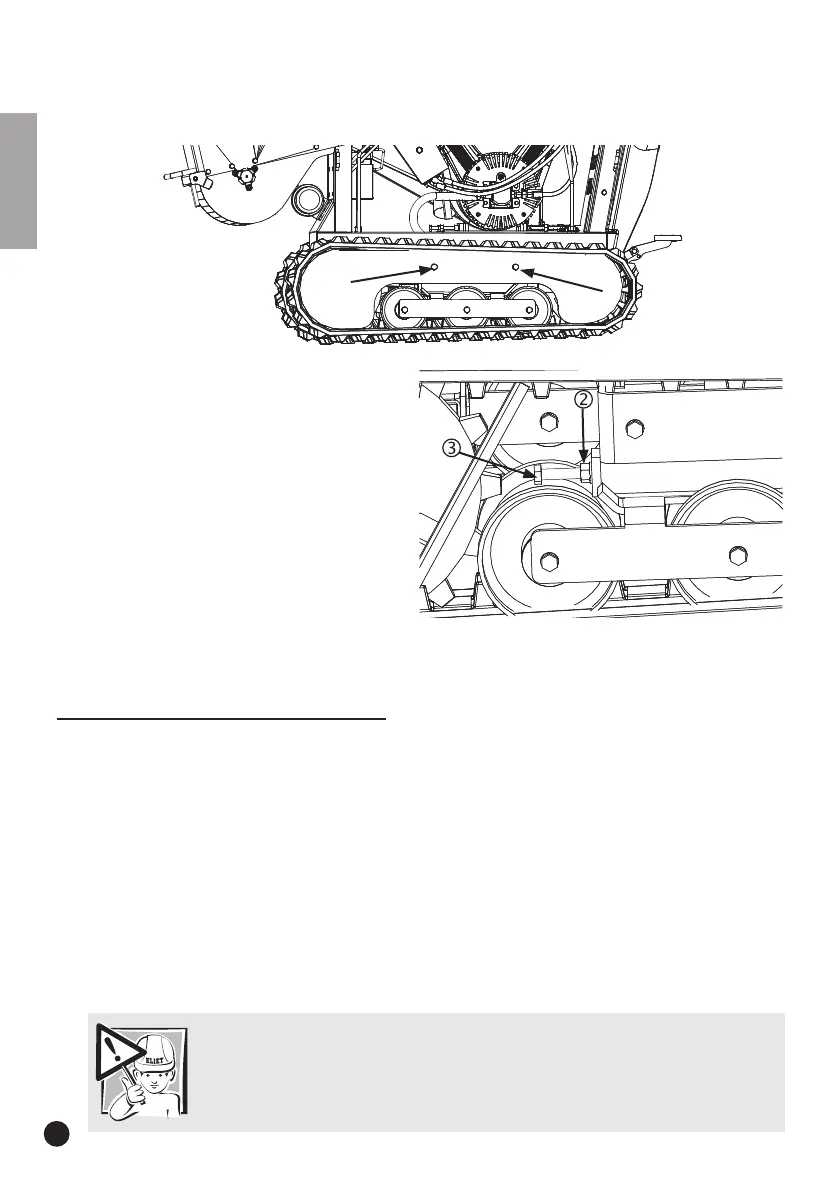

B. Adjusting the tension

• Loosen the 2 bolts (M10, SW17) first and then remove the guard protecting the track guides.

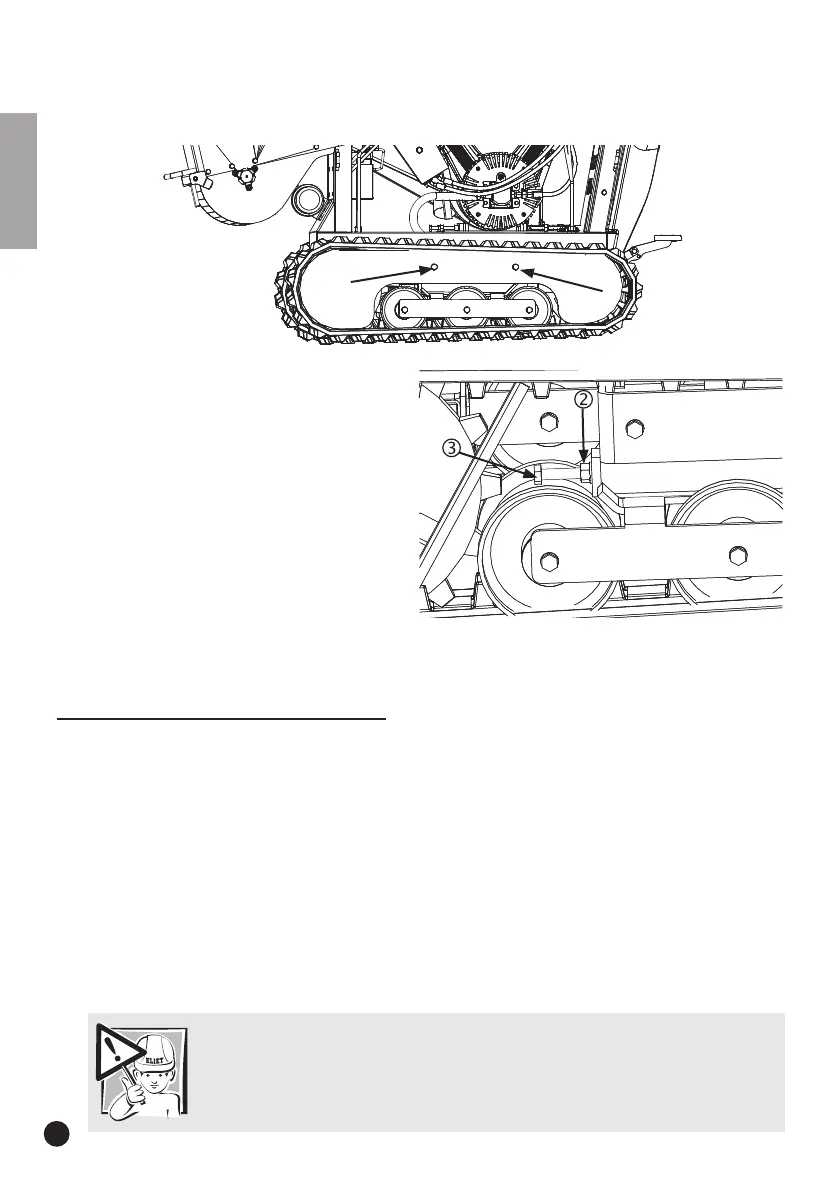

• Unscrew the lock nut (2) (M12 slw19).

• Screw in the central clamping bolt (3) until

all the slack is taken up. (M12 slw19)

• Check the tracks for correct tension and

turn the clamping bolt (3) further inwards

(or outwards if track tension is too high).

• Remember to tighten the lock nut (3) to

secure the clamping boltr (2).

• As you go along, thoroughly clean and lubri-

cate the track holder.

• Refit the guard using the 2 bolts using a reverse sequence to that given for removal.

11.4.9 General lubrication (Lubrication)

In view of the fact that the shredders often operate in extreme conditions, Eliet considers it im-

portant to use high-quality materials. ELIET therefore recommends the use of special lubricants

(from the assembly stage onwards).

The following parts require regular lubrication :

• Pivot points and friction surfaces (read “11.4.9.1 Lubrication of pivot points and friction surfa-

ces” on page 65).

• Grease zerks (read “11.4.9.2 Greasing via the grease zerks fitted” on page 66).

• Bearing (read “11.4.9.3 Lubricating the bearings” on page 67).

• Chains and gears (read “11.4.9.4 Lubricating the chains and the gearwheels” on page 67).

Caution:

Before performing lubrication, make sure to switch off the engine and to

remove the key from the ignition switch. Gloves must also be worn during this

maintenance.

Loading...

Loading...