October 2015

Service Instructions

127072E Rev. C

23

Section 5: Module Removal and Installation

Module Removal and Installation

NOTE:

To identify hex cap screws (7-100) from hex cap screws (7-80), hex cap screws (7-100) will

be located to the left and right of spring-return cartridge top dead center and will then be

counted as every other hex cap screw. To verify correct hex cap screws check the following

table for screw length.

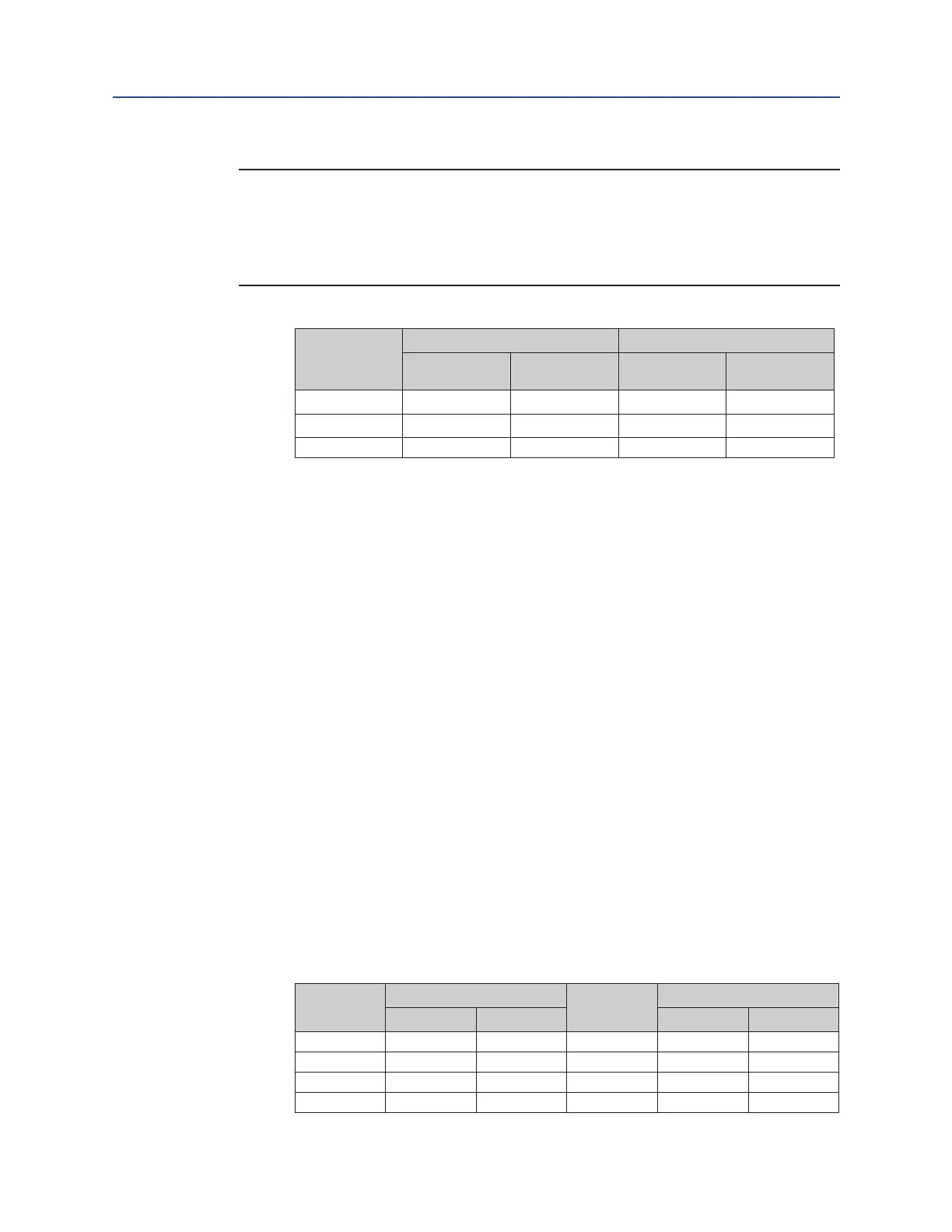

Table 4� Wire Length Requirements

MODEL

G/GC/GH/

GHC

ITEM 7-80 LENGTH ITEM 7-100 LENGTH

Inches mm Inches mm

G7 2 50.8 2.75 69.85

G8 3 76.2 4.5 114.3

G10 3.5 88.9 5.0 127

5�1�6�2 Remove override cylinder assembly from spring cartridge assembly (5-10).

5�2 M11 Override Cylinder Installation

5�2�1 Install O-ring seal (6-10) into the O-ring groove in the outboard end of spring

cartridge assembly (5-10).

5�2�2 M11 hydraulic override cylinder installation: For models G01 through G5 use step

5.2.3 and for G7 through G10 use step 5.2.4.

5�2�3 G01 through G5 M11 override cylinder installation

5�2�3�1 Insert M11 hydraulic override cylinder assembly through spring cartridge

outer end.

5�2�3�2 Install lockwashers (7-90) on to hex cap screws (7-80).

5�2�3�3 Install hex cap screws (7-80) with lockwashers (7-90) through hydraulic

override end cap (7-70) and into outer end of spring cartridge (5-10).

5�2�4 G7 through G10 M11 override cylinder installation

5�2�4�1 Insert M11 hydraulic override cylinder assembly into spring cartridge

outer end.

5�2�4�2 Install lockwashers (7-90) on to eight hex cap screws (7-100).

5�2�4�3 Install hex cap screws (7-100) with lockwashers (7-90) through hydraulic

override end cap (7-70) and into outer end of spring cartridge (5-10).

5�2�5 Torque tighten hex cap screws (7-100 and 7-80), alternately until a nal lubricated

torque, as listed in the following table, has been achieved.

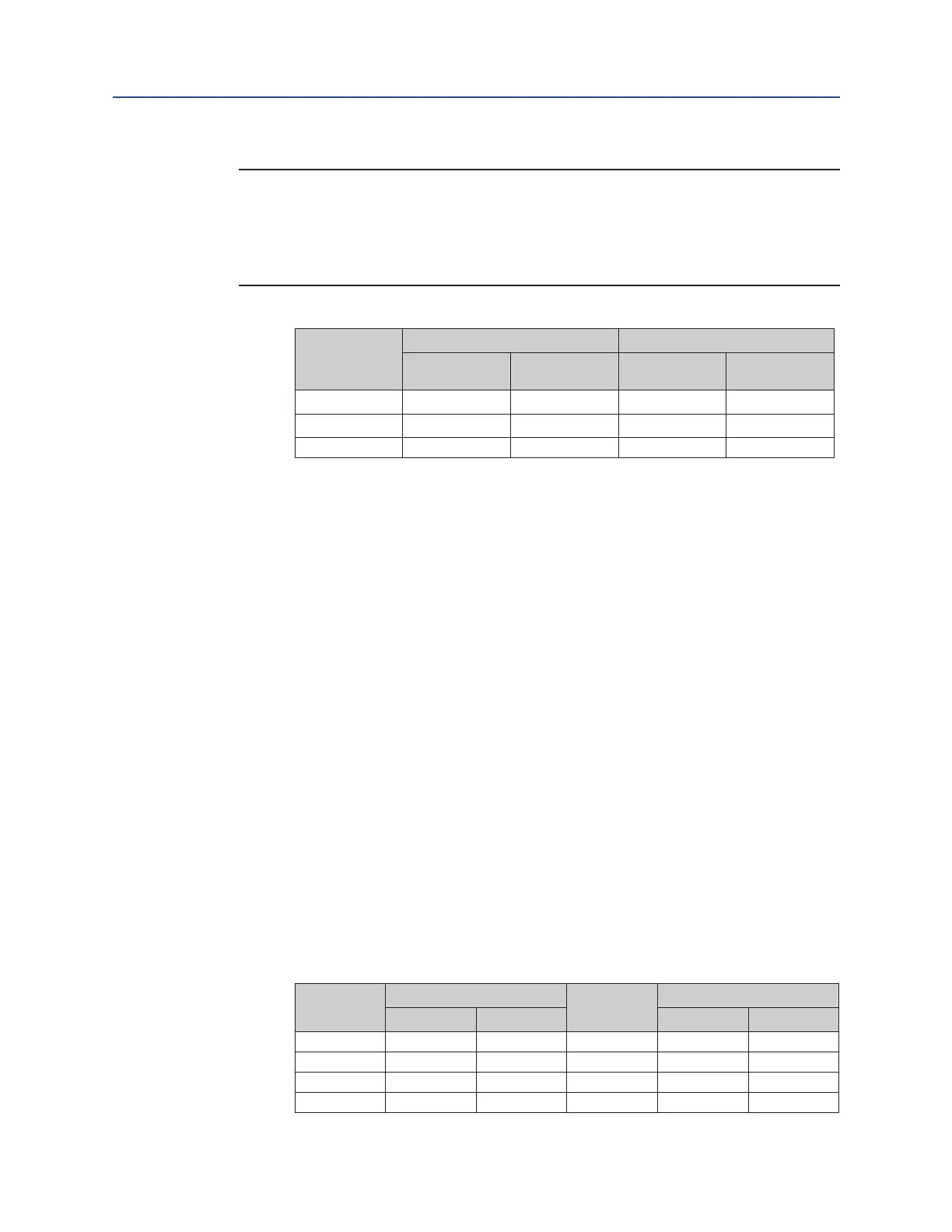

Table 5� M11 Override Cylinder End Cap to SR Cartridge Screw Torque

Model

TORQUE (±5%)

Model

TORQUE (±5%)

Lbf-ft� N-m Lbf-ft� N-m

G01 16 21.68 G5 40 54.2

G2 16 21.68 G7 80 108.4

G3 16 21.68 G8 130 176.15

G4 40 54.2 G10 190 257.45

Loading...

Loading...