October 2015

Service Instructions

127072E Rev. C

27

Section 5: Module Removal and Installation

Module Removal and Installation

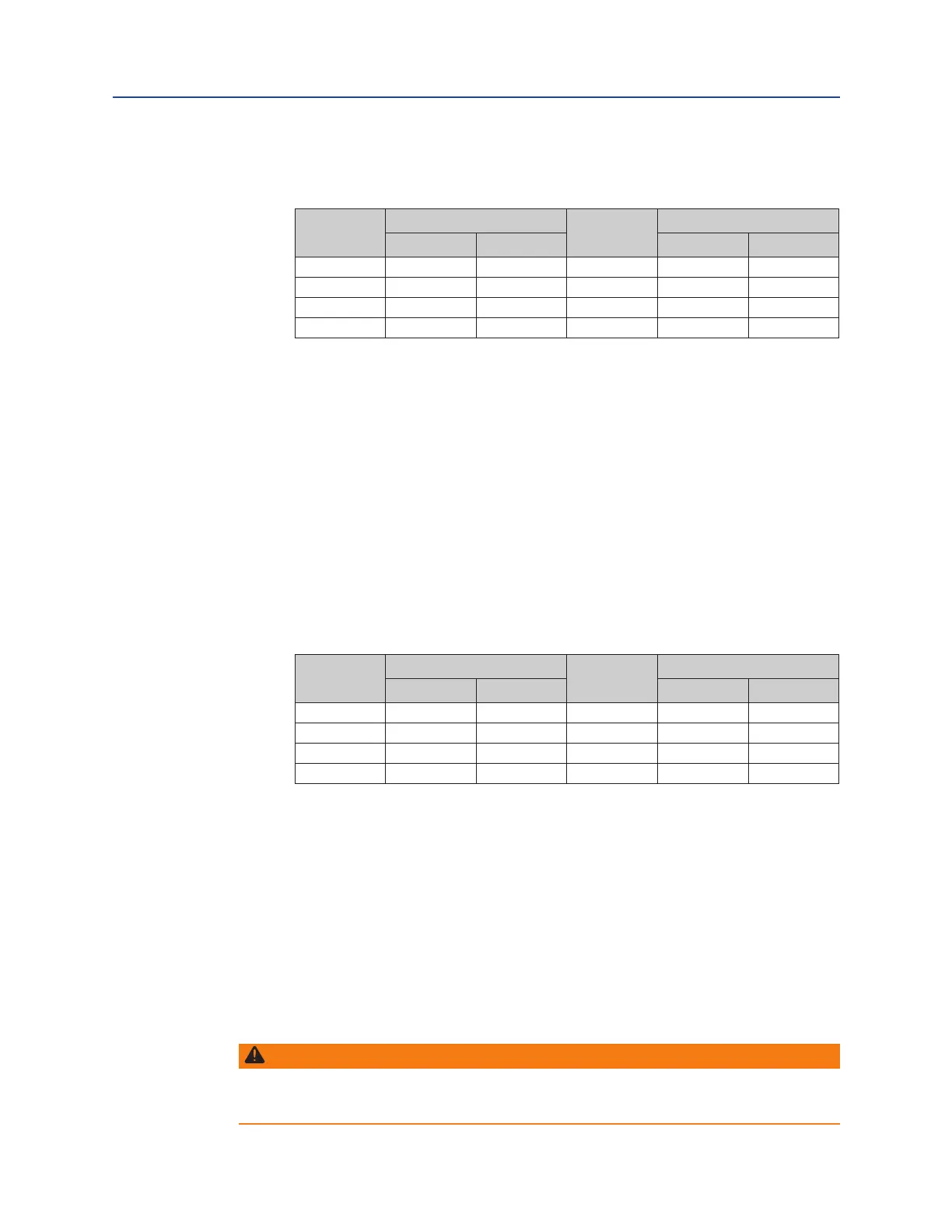

5�4�6 Torque tighten the spring cartridge tension rod as listed in the following table.

Table 7� Spring Cartridge Tension Rod Torque Table

Housing

Model

TORQUE (±5%)

Housing

Model

TORQUE (±5%)

Lbf-ft� N-m Lbf-ft� N-m

G01 50 68 G5 240 325

G2 90 122 G7 240 325

G3 90 122 G8 240 325

G4 240 325 G10 240 325

5�4�7 Install lock washers (5-30) onto hex cap screws (5-20).

5�4�8 Install hex cap screws (5-20) with lockwashers (5-30) through housing (1-10) and

into spring cartridge assembly (5-10) and tighten.

5�4�9 Install O-ring seal (6-10) into the O-ring groove in the outboard end of spring

cartridge assembly (5-10).

5�4�10 Install lockwashers (7-30) onto hex cap screws (7-20).

5�4�11 Install end cap (7-70) onto the outboard end of spring cartridge assembly (5-10).

5�4�12 Install and tighten hex cap screws (7-80) with lockwashers (7-90) through end cap

(7-70) and into spring cartridge assembly (5-10).

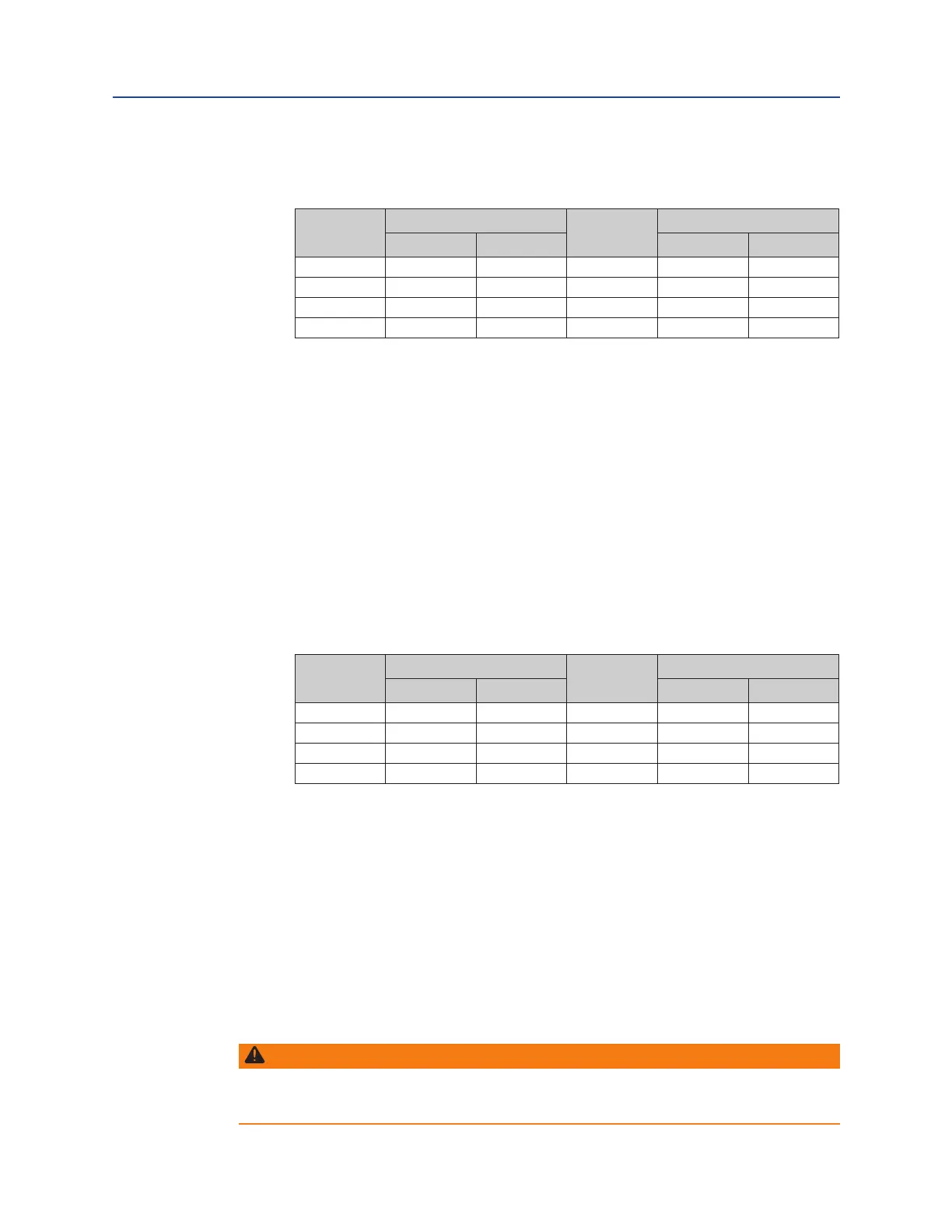

5�4�13 Torque tighten hex cap screws (7-100 and 7-80) alternately until a nal lubricated

torque, as listed in the following table, has been achieved.

Table 8� Spring Cartridge Tension Rod Torque Table

Housing

Model

TORQUE (±5%)

Housing

Model

TORQUE (±5%)

Lbf-ft� N-m Lbf-ft� N-m

G01 16 21.68 G5 40 54.2

G2 16 21.68 G7 80 108.4

G3 16 21.68 G8 130 176.15

G4 40 54.2 G10 190 257.45

5�4�14 If removed install stop screw nuts (1-190) onto stop screws (1-180).

5�4�15 If removed install O-ring (2-90) onto stop screws (1-180).

5�4�16 If removed install two stop screws (1-180) into two stop screw holes on the front

of housing (1-10).

5�4�17 Adjust both stop screws (1-180) back to settings recorded earlier in Section 5.

5�4�18 Tighten both stop screw nuts (1-190) securely.

5�5 Hydraulic Power Module Removal

WARNING: CONFIRM EXTENDED SPRING POSITION

The spring cartridge must be checked to verify that the spring(s) are in their extended

position before the power module is removed from the actuator.

Loading...

Loading...