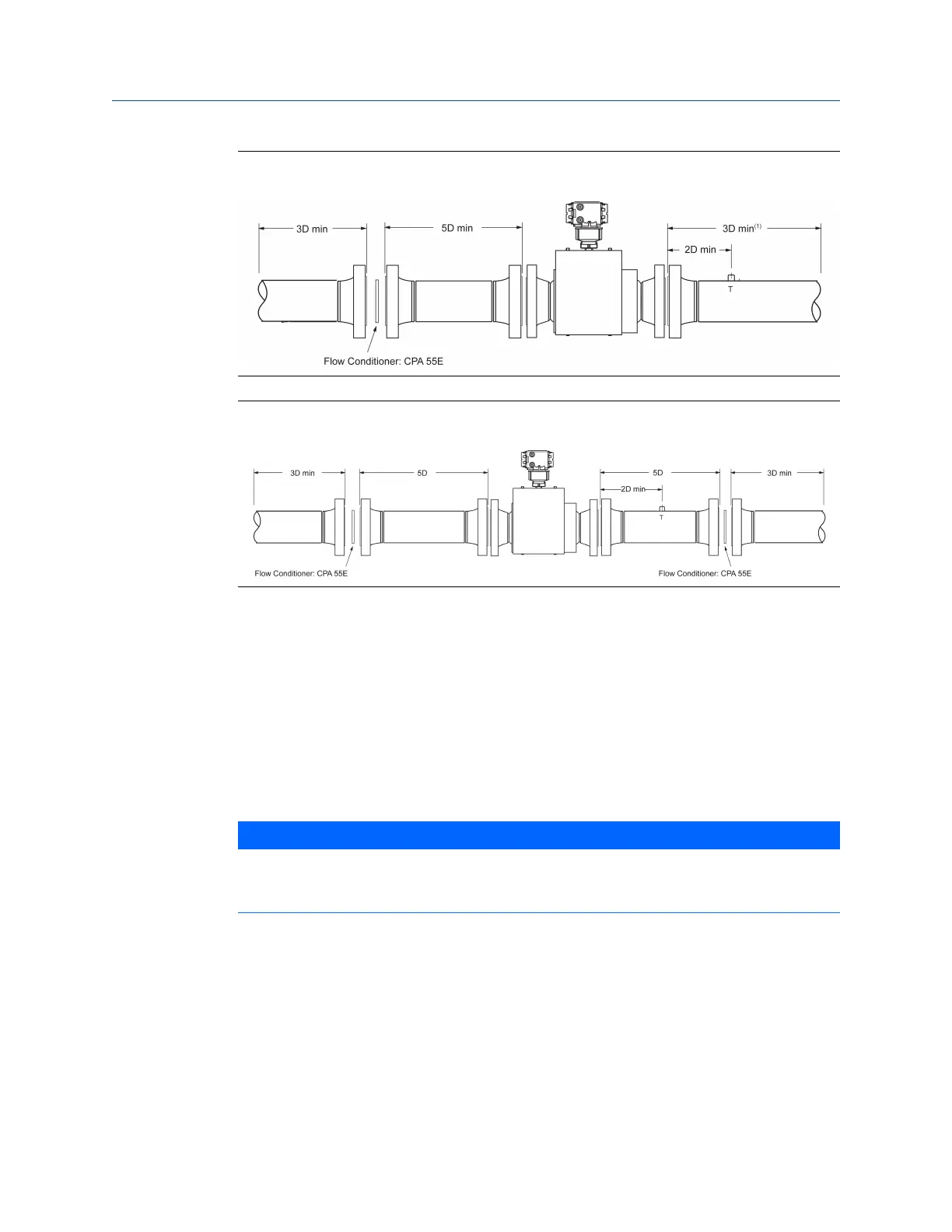

Piping Recommendation for Gas Ultrasonic Meter with Flow Conditioner

(compact installation)

Figure 2-8:

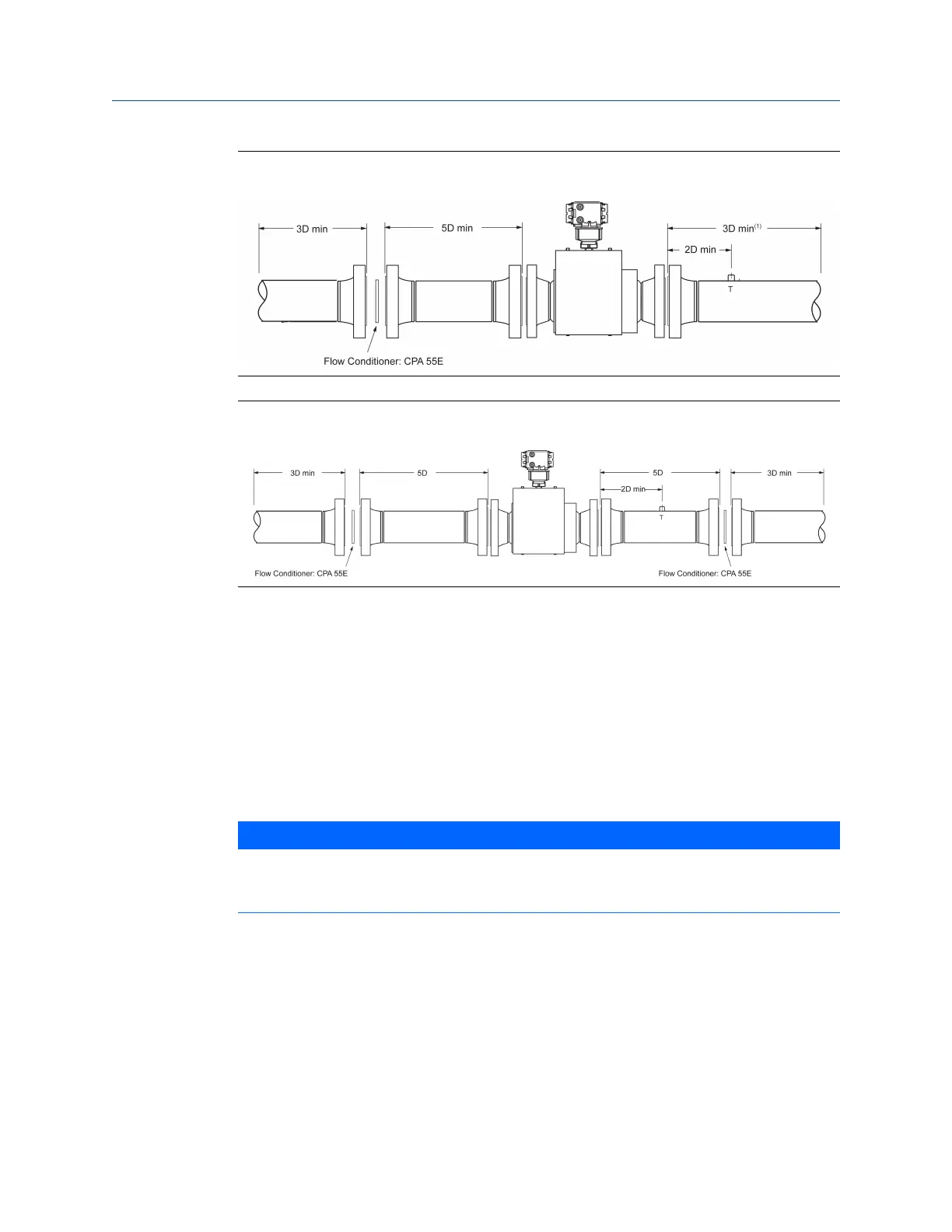

Piping Recommendation Bi-directional Gas Ultrasonic Meter with Flow

Conditioner (compact installation)

Figure 2-9:

All pipe lengths are minimum:

• P = Pressure measurement location

• T = Temperature measurement location

(1) For best results, flow conditioning is recommended

(2) D = Nominal pipe size in inches (i.e., 6 in pipe; 10D = 60 in)

http://www2.emersonprocess.com/en-US/brands/daniel/Flow/ultrasonics/Pages/

Ultrasonic-Series-3400.aspx

NOTICE

To access the product datasheet from the Daniel products page (above link), select the Daniel

Gas Ultrasonic Flow Meter link, click the Documentation tab, expand the Data Sheets - Bulletins

- Catalogs tab, then select the Data Sheet.

• The meter is provided with dowel pins to align the meter body bore with the bore of

the mating piping.

• Daniel 3410 Series Ultrasonic Gas Flow Meters should be mounted in horizontal

piping with the chord paths horizontal.

Mechanical installation

32 Gas Ultrasonic Flow Meter

Loading...

Loading...