24

CLARKSON SLURRY KNIFE GATE VALVES

KGA

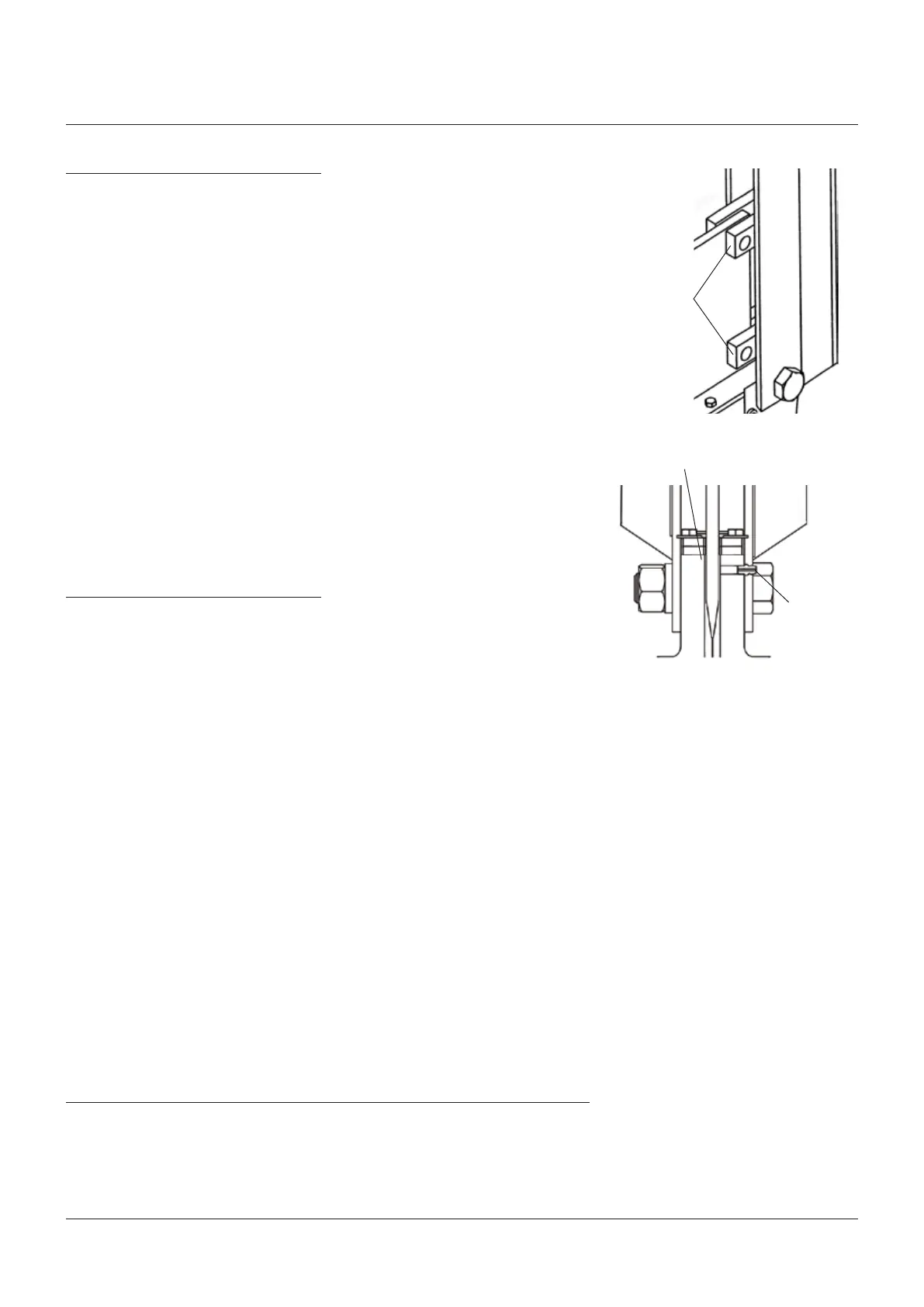

FIGURE 4

Lockout

brackets

Wiper assembly

Lubrication

fitting

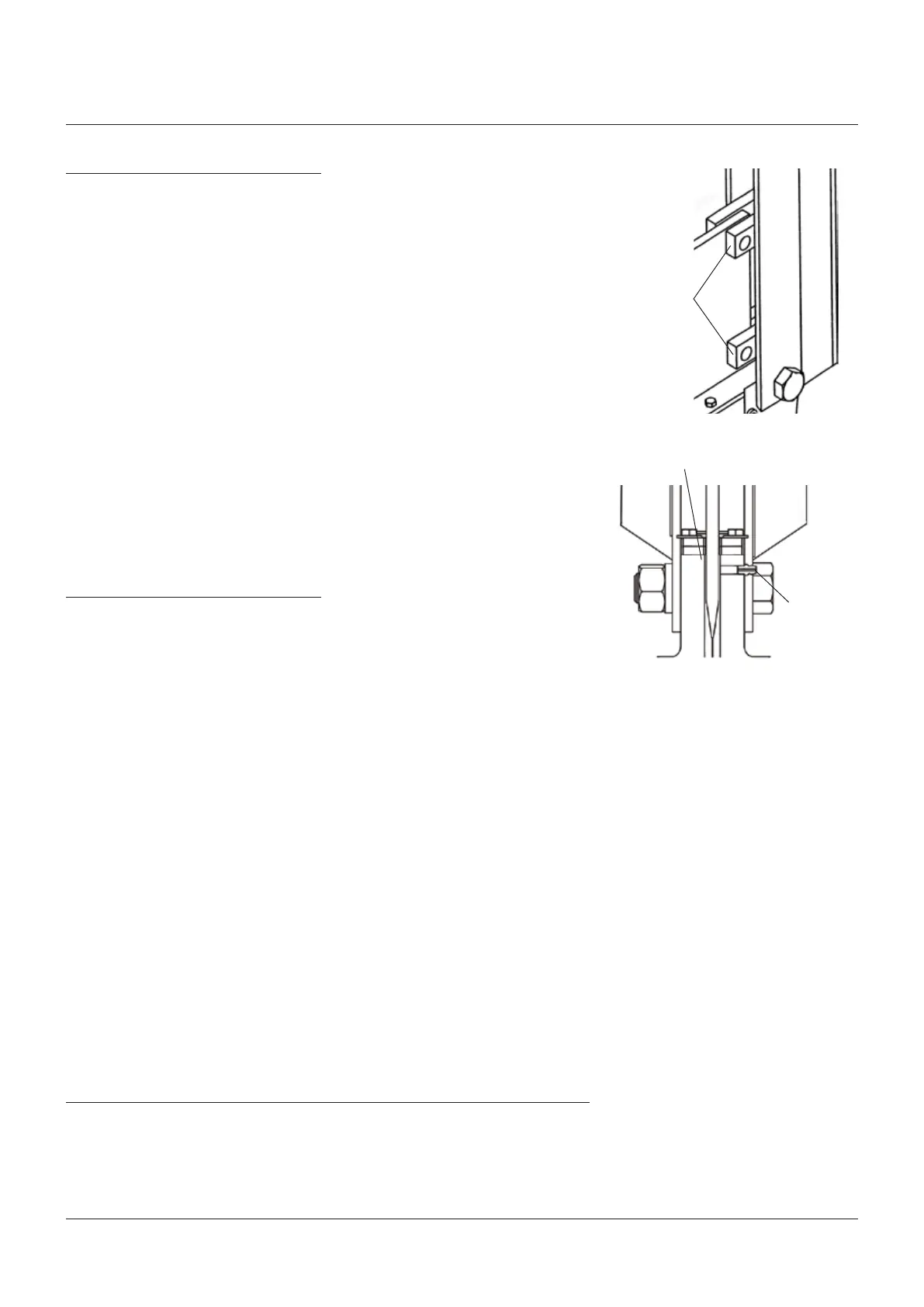

FIGURE 5

24 LOCKOUTS

Lockouts are optional on the KGA. If provided,

the open-closed lockout brackets are

designed to resist the normal valve operating

thrust. In order to assure complete lockout

compliance, any AC, HC or EM actuated valve

must be placed in a ZERO ENERGY STATE by

isolating all potential energy sources including

electricity, operator supply air or hydraulic

fluids. Please contact factory for complete

details.

CAUTION

Valves supplied with spring to extend (fail close) or

retract (fail open) cylinders contain a mechanical

spring which is compressed. In this case, the

mechanical energy of the compressed spring

cannot be placed in a ZERO ENERGY STATE.

Take extreme care when inserting and removing

the lockout pin. If the valve is actuated or the

opposing pneumatic force is removed during

the insertion process, the cylinder rod, gate and

accompanying hardware will move and injury

could occur.

25 GENERAL MAINTENANCE

We recommend that all Clarkson products be

inspected at least every 60 days. The following

points should be examined and corrected as

required:

1. Exterior overview: piping system

components are subject to certain levels of

erosion and corrosion. Periodic inspections

should be made as valves/components

may wear over time. Regular inspection

of the housing assembly and gate should

be performed, check for general signs

of corrosion, component wear and/

or damage caused by process media.

Severe applications may require additional

inspection types and/or frequency.

2. Valve stems, extension stems, and stem

nut: look for excessive corrosion, galling or

lack of lubrication. If valve stem requires

lubrication, utilize the grease fitting provided

and pump standard bearing grease through

the yoke hub to lubricate the stem and

stem nut assembly. Additional lubrication

may be applied directly onto stem or

stem threads. (Use material which meets

ASTM 4950 GBLB.)

APPROVED SILICON BASED LUBRICANTS

Dow III - Dow corning Complex 821 - NFO

Dow 44 - Dow corning Dow 7 - Dow corning

Rhodorsil 111 - Rhone-poulenc Compound G661 - G E

Sil glyde - AGS Company

For compatibility of other lubricants, consult Emerson Engineering.

Note: failure to use the recommended type

of lubricant will considerably reduce the life

ofboth the sleeves and secondary seal. Under

no circumstances should a hydrocarbon-based

lubricant be used. The use of improper

lubrication will void anyremaining warranty.

3. If possible stroke the valve through the full

open and closed position to make sure it is

functioning properly.

Note: it is normal for the KGA valve to

discharge media during opening and

closingcycles.

4. Valve housing and sleeve lubrication

A) The KGA valve is equipped with

lubrication fittings located in the chest

of the valve. Through these lubrication

fittings, approved silicone based-

lubricant can be inserted into the valve

chest area. This is the primary means

ofgate and sleeve lubrication.

B) As a minimum, the Clarkson KGA valves

should be lubricated every 100strokes

for NPS 3 - 10 (DN 80 - 250) sizes

and every 50strokes for NPS 12 - 60

(DN 300 - 1500) sizes. An individual

application may require more or less

frequent lubrication depending on

the process and chemistry. If a valve

cycles very infrequently, less than once

per month, lubrication prior to each

stroke is recommended. (See below

forapprovedlubrication).

C) The gate may also be lubricated by

applying lubricant directly onto the

exposed gate surface.

D) Sleeve wear can be minimized if the

valve gate is scraped or wiped clean

occasionally.

E) For dry material handling service, liquid

or grease type lubricants should not be

used.

Loading...

Loading...