32

CLARKSON SLURRY KNIFE GATE VALVES

KGA

31 FIELD REPLACEMENT OF GATES

CAUTION

Since this procedure may be performed with the

valve in an active pipeline, plant standard safety

procedures must be followed. Use of personal

protective equipment, tag out or other plant

standard safety procedures must be followed.

If valve is removed for this service, assure line

is not pressurized before removing valve. Valve

assembly and parts may be heavy, use proper

lifting and support techniques, refer to Lifting,

Section 33.

1. Open the valve, so the gate is in the fully

raised position.

2. Remove the cotter pin and clevis pin from

the gate. It may be necessary to actuate

the valve down slightly in order to relieve

pressure on the clevis pin to facilitate

removal.

3. Actuator assembly removal:

Smaller valves: remove the frame to

housing bolts of one side except for the

lowest bolt on the opposite side of the

frame. This bolt will act as a pivot point for

the frame / actuator assembly. Pivot the

frame / actuator assembly away from the

valve and temporarily support.

Larger valves: remove the frame to housing

bolts. Lift the frame and actuator assembly

off the housing assembly to allow gate

removal.

4. Remove the old gate.

5. Inspect the gate for sharp edges or

excessive damage. Some scoring will

occur in normal use. If the gate has been

bent beyond

1

/

16” (1.5 mm) permanent

deflection at the center, straighten or

replace. If straightening is performed,

use considerable care to minimize marks

on gate surface. Scores or other distress

marks may be cleaned up with a belt

sander. Machining the gate surface is not

recommended. Light scale buildup may

be removed with a putty knife or gasket

scraper. Inspect the gate for wear and

roughness. Use a disc grinder or belt sander

to remove rough surfaces. Take particular

care on the leading and beveled edge to

remove burrs and other sharp edges.

6. Apply a liberal amount of recommended

lubricant to the two tapered faces of the

‘sharp end’ of the gate.

7. Press the gate into the valve housing

assembly until the mark drawn on the gate

reaches the top of the retainer plate or

gate reaches approximately dimension A,

Table5, Figure 13.

8. Reinstall the actuator / frame assembly

withthe housing / frame fasteners loosely.

9. Reconnect the gate to the actuator. (In order

to facilitate installation and future removal,

a coating or anti-seize compound should be

applied to the outside of the clevis pin over

the yoke contact area.)

10. ‘Stretch’ the frame / actuator assembly

with respect to the housing by lifting the

frame / actuator assembly to its maximum

movement up away from the housing

assembly. Tighten the frame / housing bolts

and verify the tightness of the actuator to

frame bolts.

11. Tighten all of the frame to housing bolts.

12. Test stroke the valve to verify travel and

wiper / wiper retainer interference with

the yoke. Adjust / replace the wipers as

required.

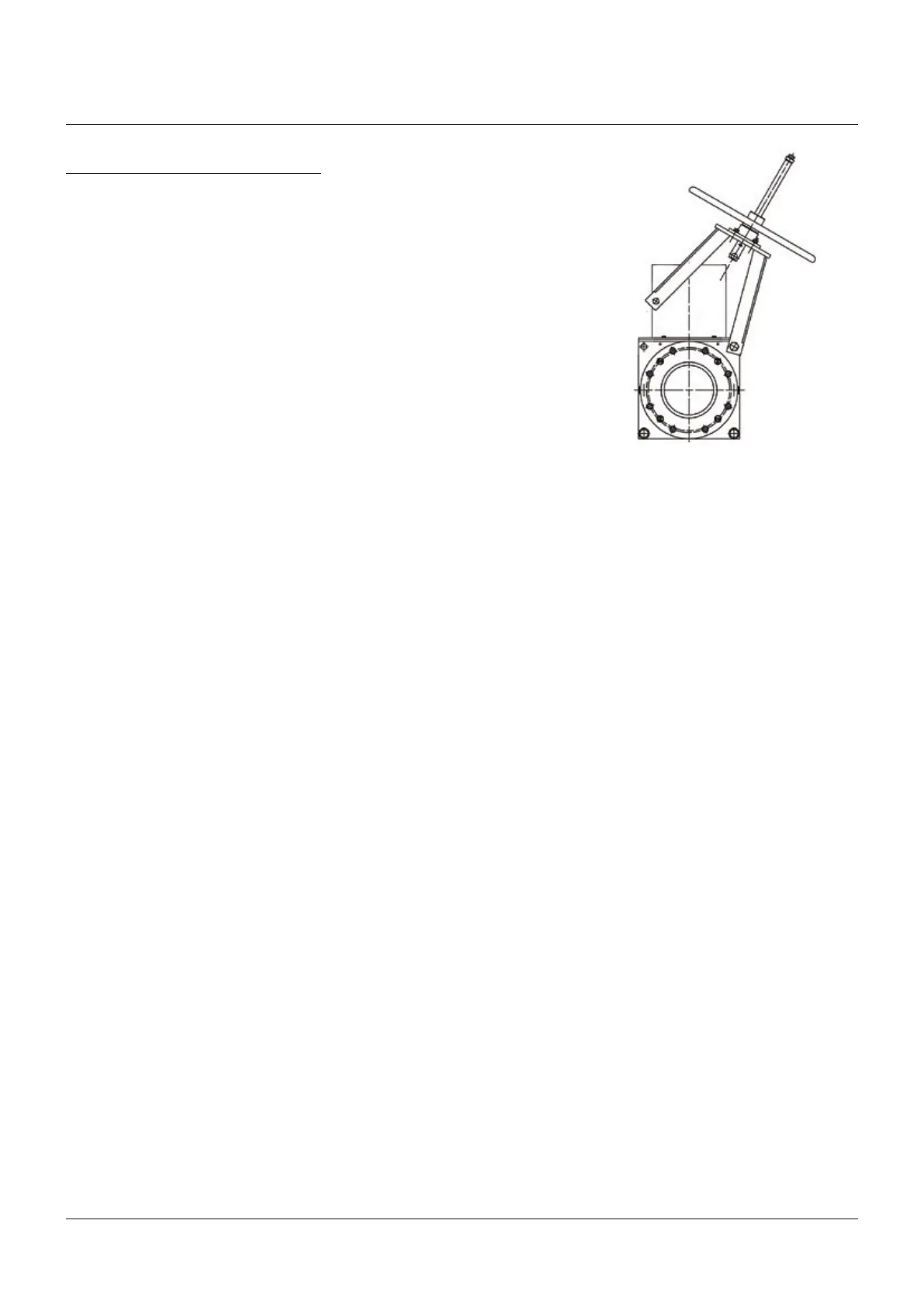

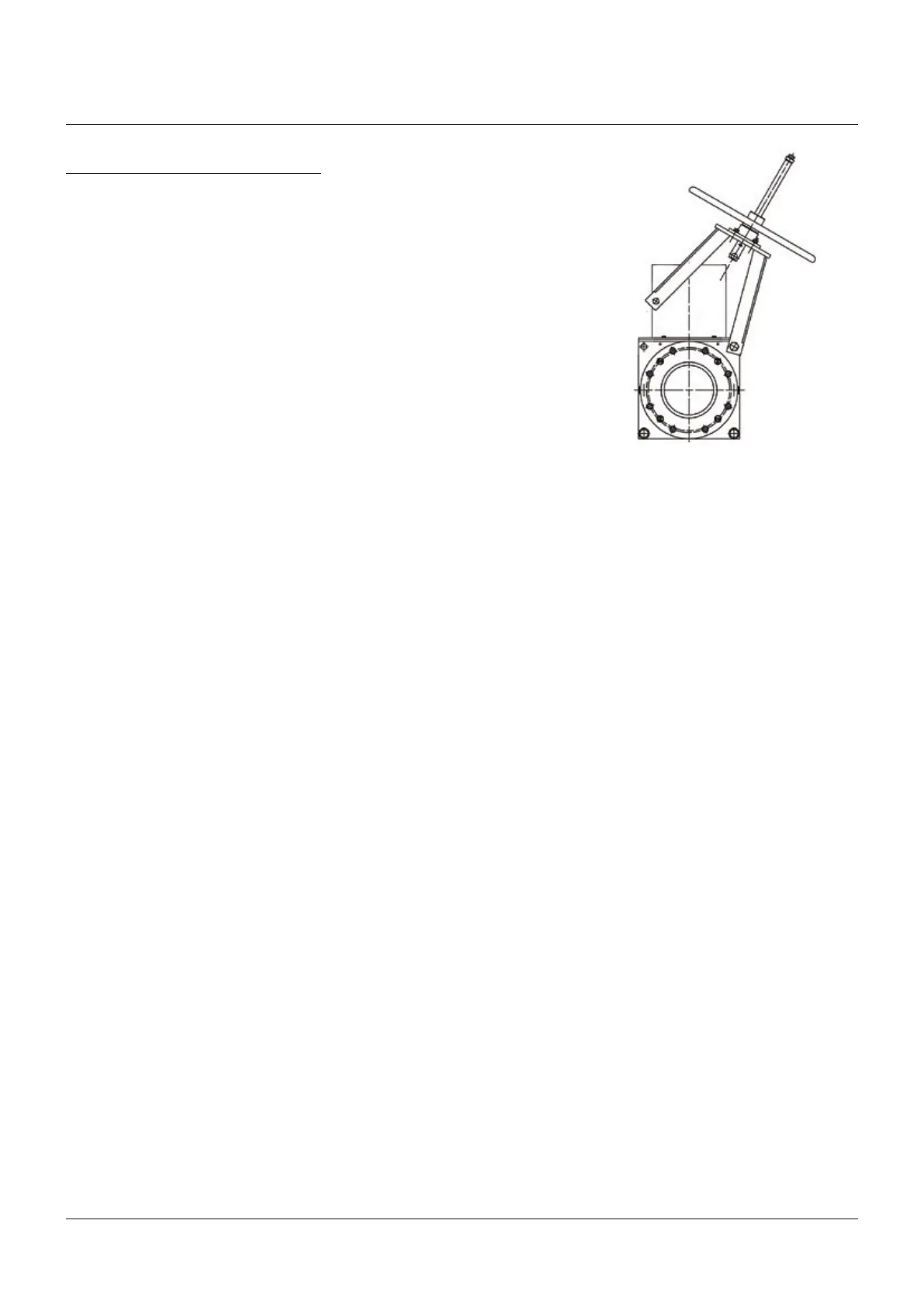

For gate replacement, smaller valves may

have the actuator frame swung out of the way

as illustrated here. Remove frame bolts on

one side only and loosen the opposite side

just enough to allow movement. Be sure and

properly support weight of actuator assembly,

taking care to avoid injury.

FIGURE 14

Loading...

Loading...