4

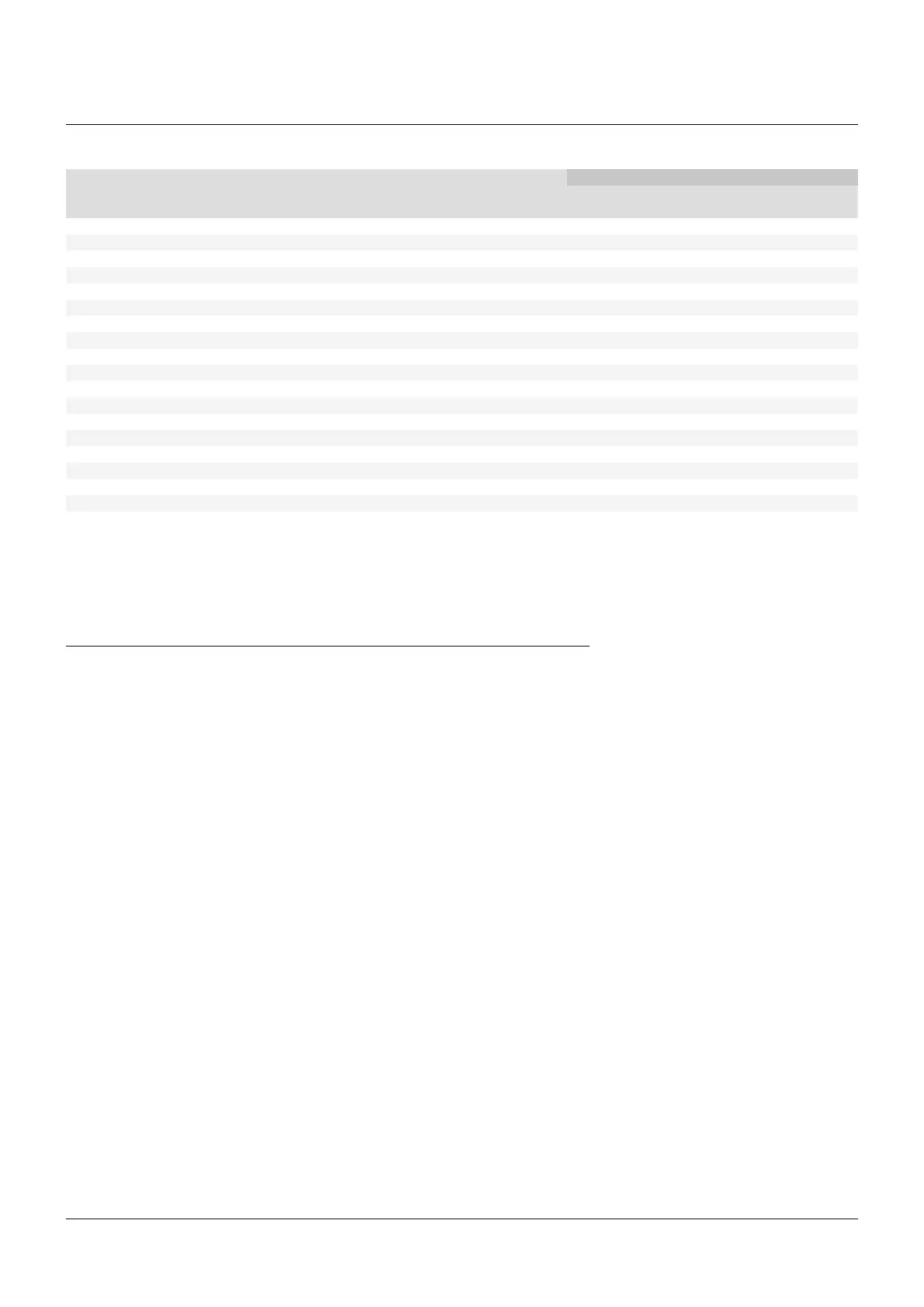

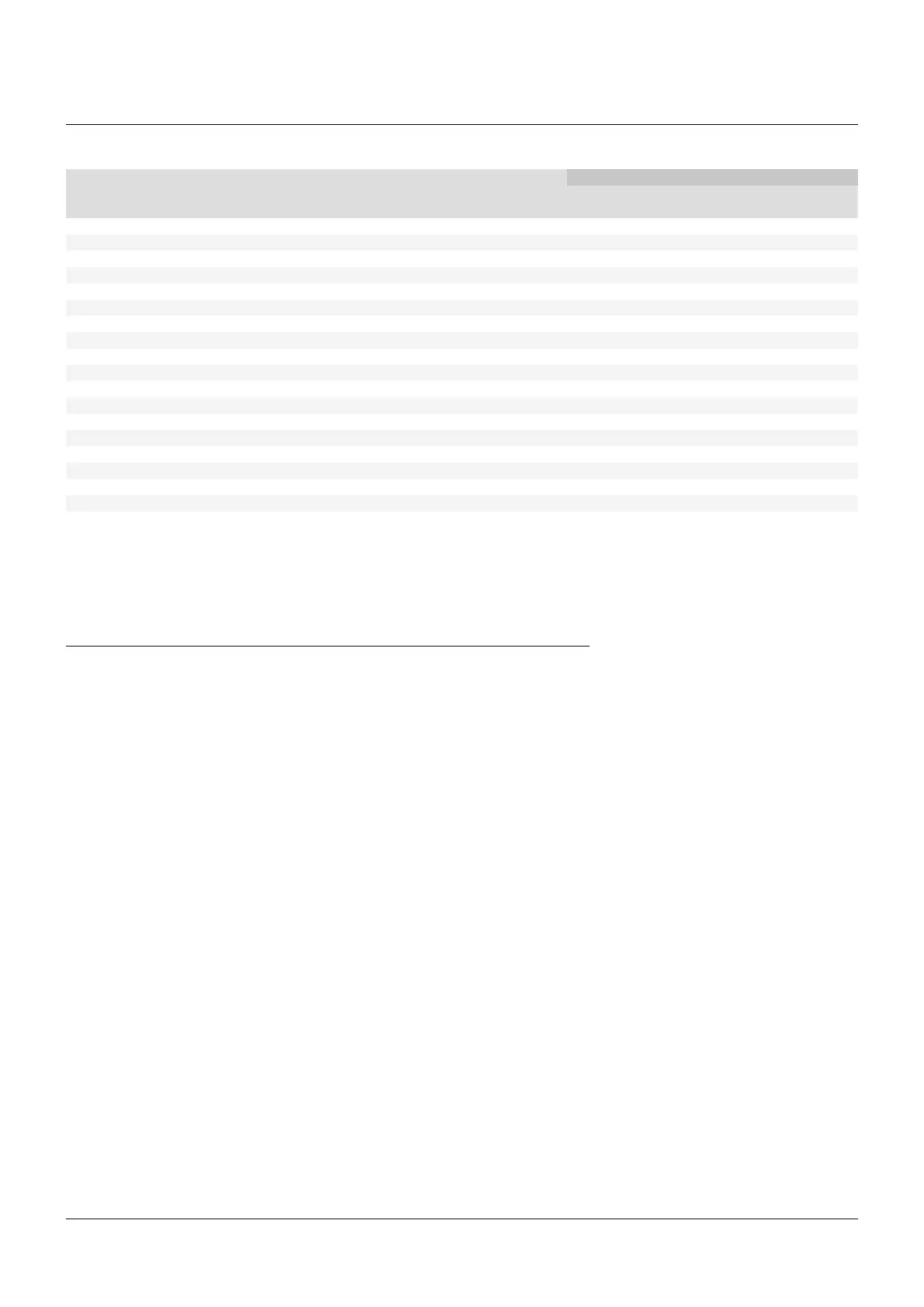

3 80 7½ 190.50 6 152.40 4 ⅝ - 11 2 50.80 2½ 63.50

4 100 9 228.60 7½ 190.50 8 ⅝ - 11 2 50.80 2½ 63.50

6 150 11 279.40 9½ 241.30 8 ¾ - 10 2 50.80 2½ 63.50

8 200 13½ 342.90 11¾ 298.45 8 ¾ - 10 2¼ 57.15 2¾ 69.85

10 250 16 406.40 14¼ 361.95 12 ⅞ - 9 - - 3 76.20

12 300 19 482.60 17 431.80 12 ⅞ - 9 - - 4 101.60

14 350 21 533.40 18¾ 476.25 12 1 - 8 - - 4½ 107.95

16 400 23½ 596.90 21¼ 539.75 16 1 - 8 - - 4¾ 120.65

18 450 25 635.00 22¾ 577.85 16 1⅛ - 7 - - 5½ 139.70

20 500 27½ 698.50 25 635.00 20 1⅛ - 7 - - 5½ 139.70

24 600 32 812.80 29½ 749.30 20 1¼ - 7 - - 6 152.40

26 650 34¼ 869.95 31¾ 806.45 24 1¼ - 7 - - 6 152.40

30 750 38¾ 984.25 36 914.40 28 1¼ - 7 - - 7 177.80

36 900 46 1168.40 42¾ 1085.85 32 1½ - 6 - - 8½ 177.80

42 1050 53 1346.20 49½ 1257.30 36 1½ - 6 - - 9 203.20

48 1200 59½ 1511.30 56 1442.40 44 1½ - 6 - - 9½ 241.30

54 1350 66¼ 1682.80 62¾ 1593.90 44 1¾ - 5 - - 10½ 241.30

60 1500 73 1854.20 69¼ 1759.00 52 1¾ - 5 - - 11 266.70

CLARKSON SLURRY KNIFE GATE VALVES

KGA+

4 OPERATION

TABLE 3 - BOLTING DIMENSIONS

Valve size

Flange

diameter

Bolt circle

diameter Bolt holes

no.

Bolt

size/thread

Bolt lengths (see note)

Without retainer flg. With retainer flg.

NPS DN inch mm inch mm UNC inch mm inch mm

NOTES

• Flange dimensions per ASME B16.5/150 for NPS 2 - 24 (DN 50 - 600) and MSS SP44 for NPS 26 - 60 (DN 650 - 1500).

• Type B standard washers are not included in bolt / stud sizing.

• Mating flange thickness assumed to match ASME B16.5/150 for NPS 2 - 24 (DN 50 - 600) and MSS SP44 for NPS 26 - 60 (DN 650 - 1500).

1. Clarkson slurry knife gate valves are

suitable for on-off service only. They are

notto be used in a throttling application.

2. To close the valve and provide isolation,

the actuator (handwheel, bevel gear,

air/hydraulic cylinder or electric motor

actuator) moves the metal gate in a linear

motion between the elastomeric sleeves

to shut off the flow. To open, reverse the

operation and the gate moves up and out

from between the sleeves, opening the

valveport.

3. Matching elastomer sleeves seal against

each under a high compression load

when the valve is open, creating the valve

pressure vessel. When the valve is closed,

the sleeves seal against the gate face,

isolating upstream from downstream.

SeeFigures 2 and 3.

Note: it is normal for the KGA+ to discharge

media during opening and closing cycles.

This helps prevent any solids from building

up between the sleeves that would prevent

a tight seal when the valve is fully open or

closed. Discharge can be controlled with

the use of an optional splash guard. Do not

install valve over walkways, electrical or

other critical equipment without the use of

splash guards or similar considerations.

4. As the gate strokes, a gap is created

between the facing sleeves, allowing any

media that could potentially clog or jam the

valve to be purged out from between the

sleeves, and potentially expelled outside

thevalve housing to atmosphere.

5. The KGA+ valve incorporates a built-in

clean-out area at the base of the housing

assembly. The clean-out area may be

enclosed by an optional, removable

splash guard assembly. This splash guard

will allow controlled drainage of any

accumulated solids that may prevent full

gate closure. Flush water can be used to

improve the drainage efficiency. With the

splash guard in place, any solids, slurry, or

flush water ejected from the valve can be

handled in a controlled manner. See Section

‘Installation instructions for splash guard’.

6. All valves should be operated within the

design pressure and temperature ranges.

Under no circumstances should the valves

be operated at conditions outside these

parameters.

Note: actuated Clarkson valves have a

maximum recommend stroke speed of

1” (25 mm) per second. Exceeding this

speed can shorten sleeve life and may

void warranty. Speed controls provided by

factory will require adjustment in the field

to obtain proper stroke speed against actual

operating conditions.

Loading...

Loading...