10

CLARKSON SLURRY KNIFE GATE VALVES

KGA+

10. Turn the valve over so the installed sleeve

ison the flat surface.

11. Apply a silicone base lubricant to the

sealing-nose radius of the installed sleeve.

Also apply it to the second sleeve sealing

nose and O.D. of seal end.

12. Install the second sleeve, following steps

1through 11. It may be necessary to use two

or more C-clamps to pull down the second

retainer flange. Do not fully tighten retainer

flange bolts until after checking the sleeve

bores for concentricity; using a straight

edge, check the sleeve position in four (4)

places, 90 degrees apart in relation to the

installed sleeve bore I.D. Adjust as required

to make the sleeve concentric with the

othersleeve.

13. Fully tighten retainer flange bolts per

Paragraph 9.

14. Remove C-clamps, if used.

15. The valve is now ready for installation.

Keep gate in the open position until valve

isinstalled.

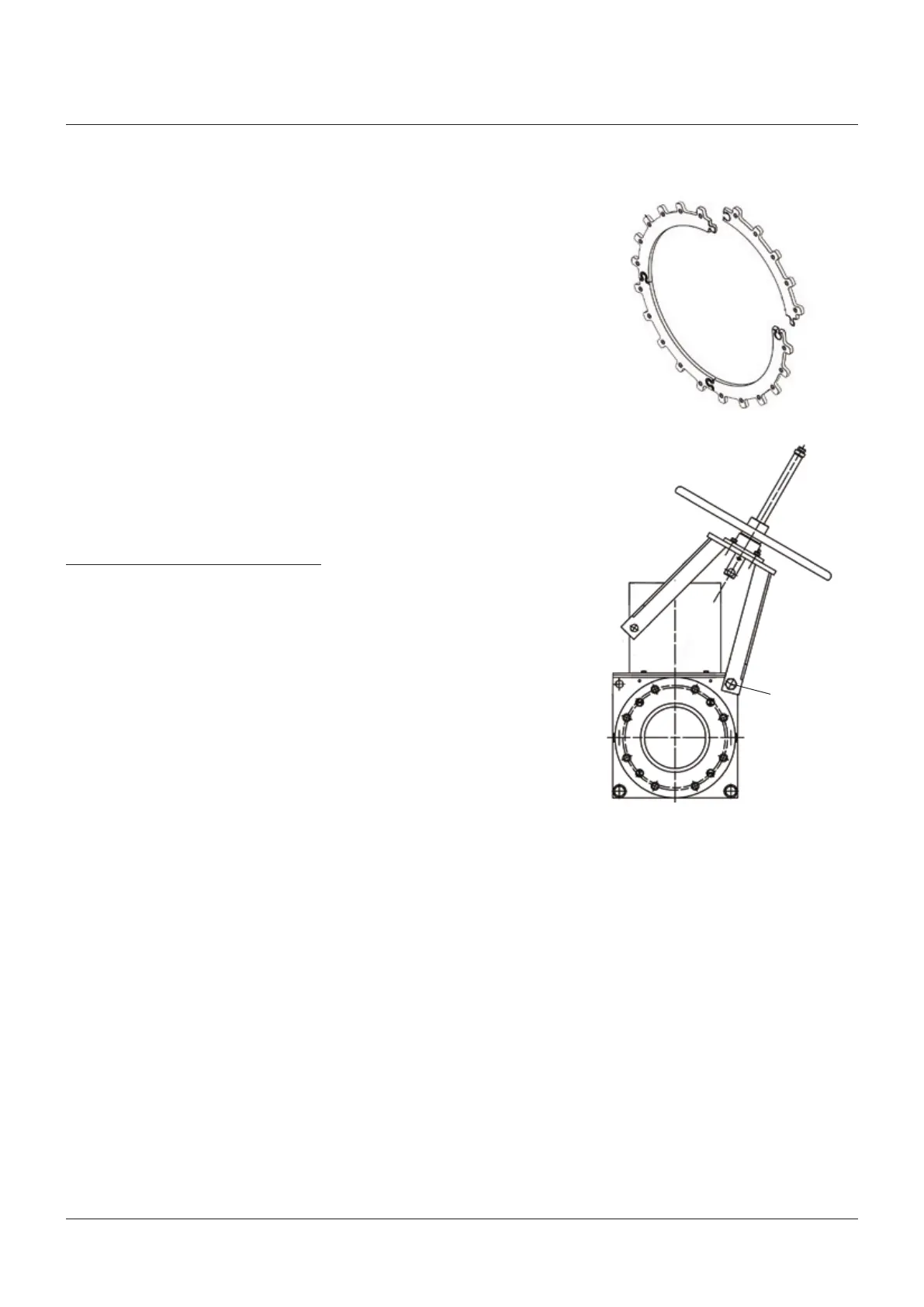

FIGURE 9

Example of a segmented retainer

10 SECONDARY SEAL REPLACEMENT

CAUTION

Since this procedure may be performed with the

valve in an active pipeline, plant standard safety

procedures must be followed. Use of personal

protective equipment, tag out or other plant

standard safety procedures must be followed.

Procedure SHOULD NOT be done with valve in

closed position. If valve is removed for this service,

assure line is not pressurized before removing

valve. Valve assembly and parts may be heavy,

use proper lifting and support techniques, refer

toLifting, Section 15.

Disassembly

1. Replacement of the secondary seal can be

accomplished without having to remove the

valve from service, however, this procedure

SHOULD NOT be done with valve in closed

position. If it is suspected that either one or

both of the elastomer sleeves have failed,

the valve should be removed from service

before secondary seal removal. If valve is

tobe removed, refer to Lifting section.

2. Open the valve, so the gate is in the fully

raised position.

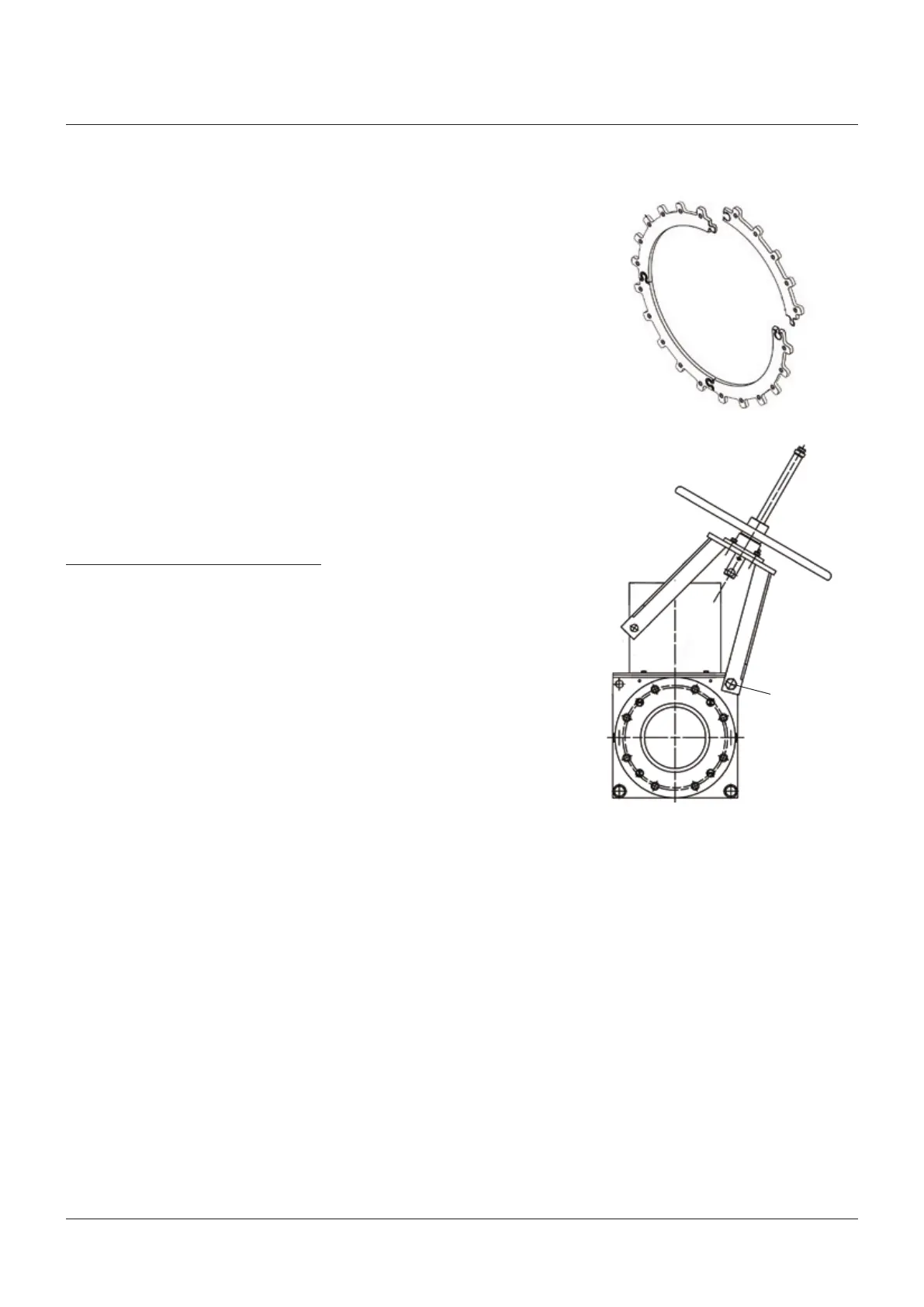

Pivot frame

on bolt

For gate and or secondary seal replacement,

smaller valves may have the actuator frame

swung out of the way as illustrated here.

Remove frame bolts on one side only and

loosen the opposite side just enough to allow

movement. Be sure and properly support

weight of actuator assembly, taking care to

avoid injury.

3. For ease of reassembly, using a permanent

marker, draw a line on the gate face along

the top of the secondary retainer plate. If

marking gate is not an option, make note

of the dimension from top of valve housing

to top of gate in full open position (refer to

Table 5, Figure 13, dimension A).

4. Remove the cotter pin from the clevis pin

and remove the clevis pin from the gate. It

may be necessary to actuate the valve down

slightly in order to relieve pressure on the

clevis pin to facilitate removal.

5. Actuator assembly removal:

Smaller valves: remove the frame to

housing bolts of one side except for the

lowest bolt on the opposite side of the frame

(see Figure 10). This bolt will act as a pivot

point for the frame / actuator assembly.

While supporting the actuator assembly,

pivot the frame / actuator assembly away

from the valve. Continue to provide support

while actuator is in this position.

Larger valves: remove the frame to housing

bolts. Lift the frame and actuator assembly

off the housing assembly to allow secondary

seal and gate removal.

6. Loosen the secondary seal retainer plate

bolts.

7. Remove the gate by lifting it out of the

secondary seal.

8. Remove all fasteners and lockwashers that

retain the secondary seal retainer plate in

position.

9. Remove the secondary seal retainer plate

bylifting it up.

10. Remove the secondary seal by inserting a

flat blade screwdriver midway along the

outside of the seal, between the seal and the

valve housing. Pry the seal up and remove.

11. Inspect the gate for sharp edges or

excessive damage. Refer to ‘Gate

replacement’ section if gate requires

replacement.

FIGURE 10

Loading...

Loading...