2

CLARKSON SLURRY KNIFE GATE VALVES

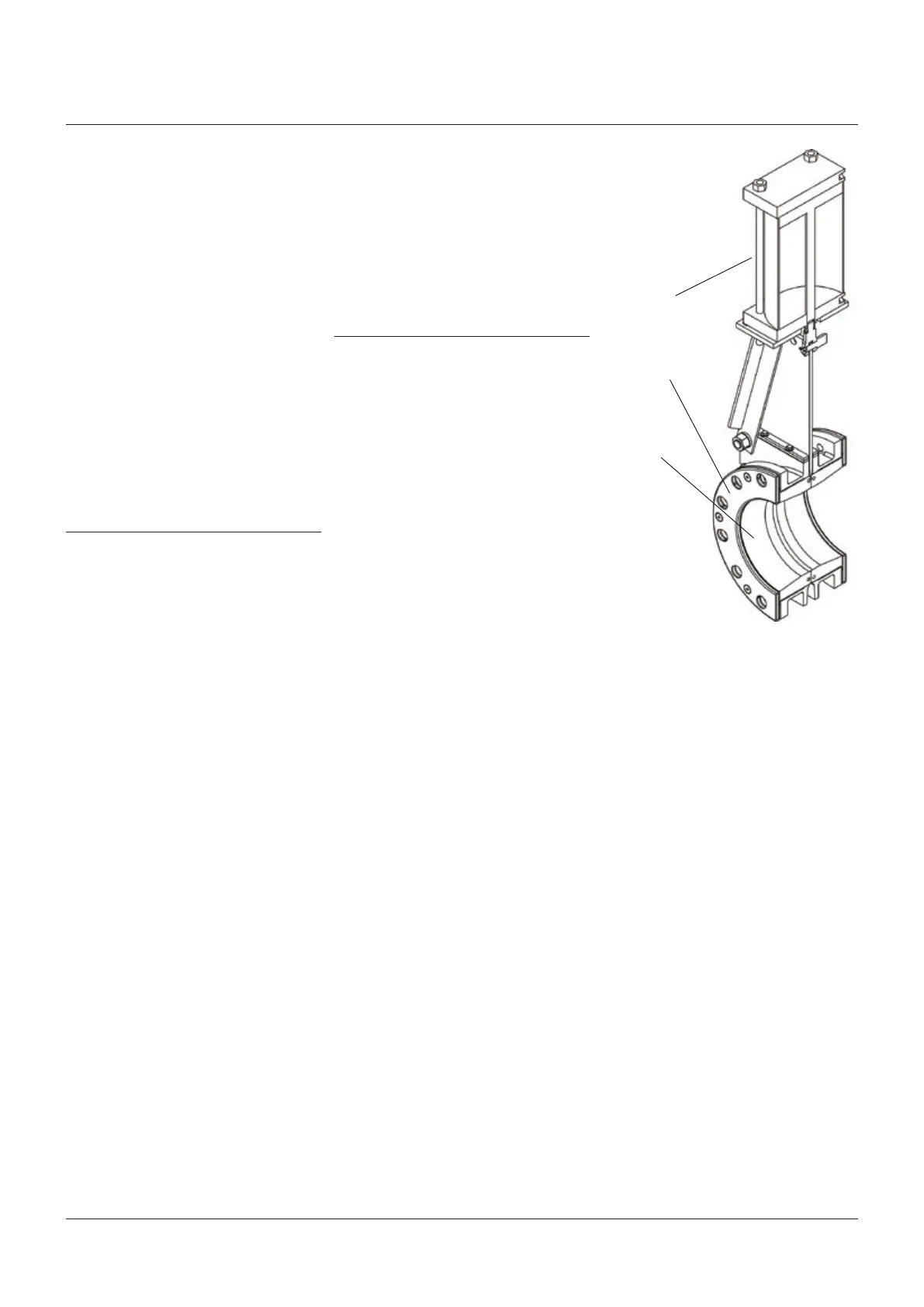

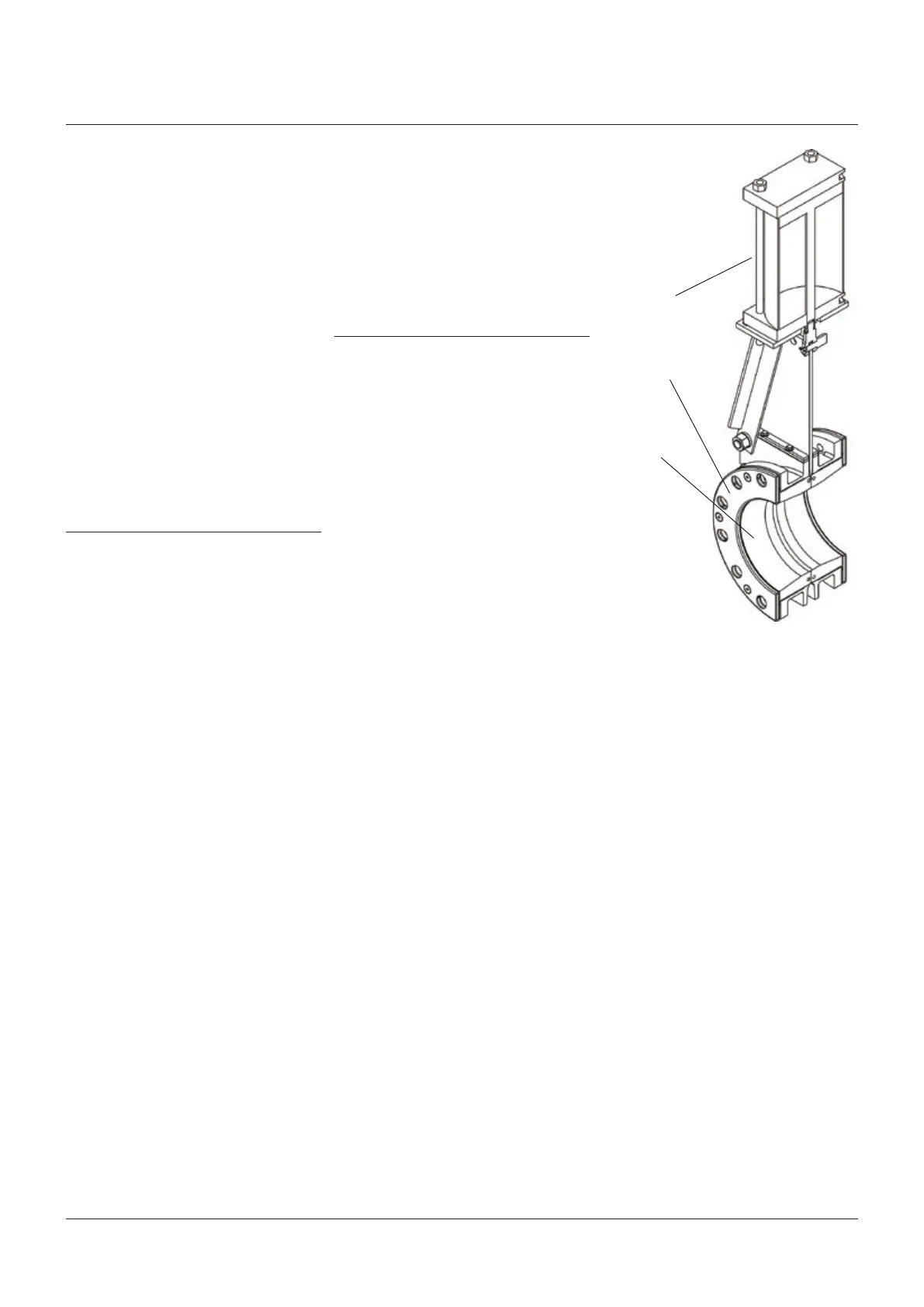

KGA+

Operators

Retainer flanges

Sleeves

FIGURE 1

2 INITIAL INSPECTION

1. Examine entire valve and report any

damageor discrepancies immediately.

2. Sleeves: visually examine the sleeves

interior, looking for chunking, irregularities

or other damage. It is not recommended you

remove the retainer flanges (if equipped).

3. Retainer flanges: sizes NPS 8 (DN 200) and

below may or may not have the optional

retainer flanges, retainer flanges are

standard on sizes NPS 10 (DN 250) and

larger. Visually examine the retainer flanges

surfaces, looking for tears, irregularities or

other damage. Check tightness of retainer

flange bolting.

4. Operators: standard manual handwheels

may be shipped loose for field installation,

be sure to fully tighten.

5. Valves are normally shipped with gate in

open position, the recommended position

for installation. Valves supplied with spring

to extend (fail close) cylinder actuators are

shipped with the gate in the closed position.

The KGA+ should be installed with the gate

in the open position, exercise caution when

applying air to open this valve and then

ensure that it is locked in the open position

when installing in the line.

6. Accessories: if provided, including

solenoids, limit switches, positioners,

etc., are tested for functionality prior to

shipment. Examine carefully for damage

which may occur during shipment.

1 GENERAL INFORMATION

1. The KGA+ is a packingless, slurry knife

gate valve. All the sealing is accomplished

by the elastomeric sleeves in the valve

housing. The sleeves also form the wear

section for the valve. The gate is removable

for inspection or replacement while the

valveisin service.

2. The KGA+ is BIDIRECTIONAL

(two-way shut-off) product and can be

installed without concern over direction of

flow. Since they will shut-off equally with

in either direction, you will find no arrows

or other indicators of a direction of flow or

seatside.

3. Clarkson slurry knife gate valves are

suitable for on-off service only. They are

notto be used in a throttling application.

4. The style, size, pressure rating and material

selection are the responsibility of the piping

system designer.

Secondary seal: the KGA utilizes a multipart

gate wiper assembly to wipe the gate and

reduce potential for discharge from the top of

the valve where the gate enters the housing

assembly. The KGA+ features a secondary seal

assembly capable of being lubricated without

disassembly. Similar to what is currently

offered on the KGD; this new seal design

incorporates an external lubrication fitting to

directly inject lubrication into the seal’s interior

(patent pending).

Simplified housing assembly: housing spacers

found on the KGA have been eliminated from

the KGA+ allowing for an easier disassembly /

assembly process.

With these changes, spare parts and

interchangeability with the prior design have

been impacted. These changes are detailed

inSections ‘Spare parts’ (KGA+ and KGA).

5. All valves should be operated within the

design pressure and temperature ranges.

Under no circumstances should the valves

be operated at conditions outside these

parameters. Do not exceed 100% of the

maximum pressure rating of the valve at

anytime during its operation. Pressure

spikes beyond the valve’s pressure rating

are solely the responsibility of the user.

Loading...

Loading...