16

CLARKSON SLURRY KNIFE GATE VALVES

KGA+

Note: it is normal for the KGA+ to discharge

media during opening and closing cycles.

This helps prevent any solids from building up

between the sleeves that would prevent a tight

seal when the valve is fully open or closed.

Discharge can be controlled with the use of an

optional splash guard or drain plate. Do not

install valve over walkways, electrical or other

critical equipment without the use of splash

guards, drain plates or similar considerations.

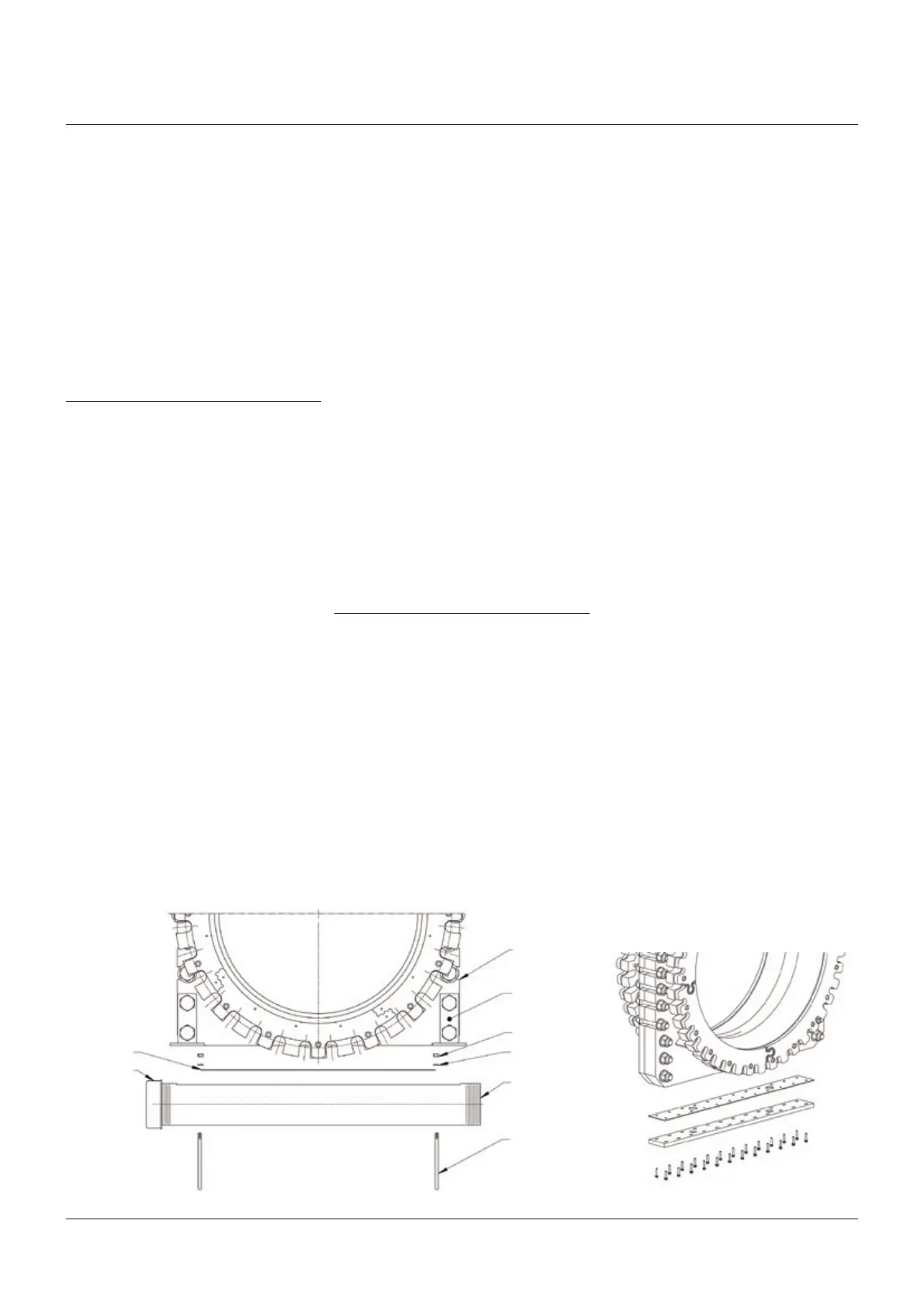

Housing

Bracket

Hex nut

Lockwasher

Splash guard

U-bolt

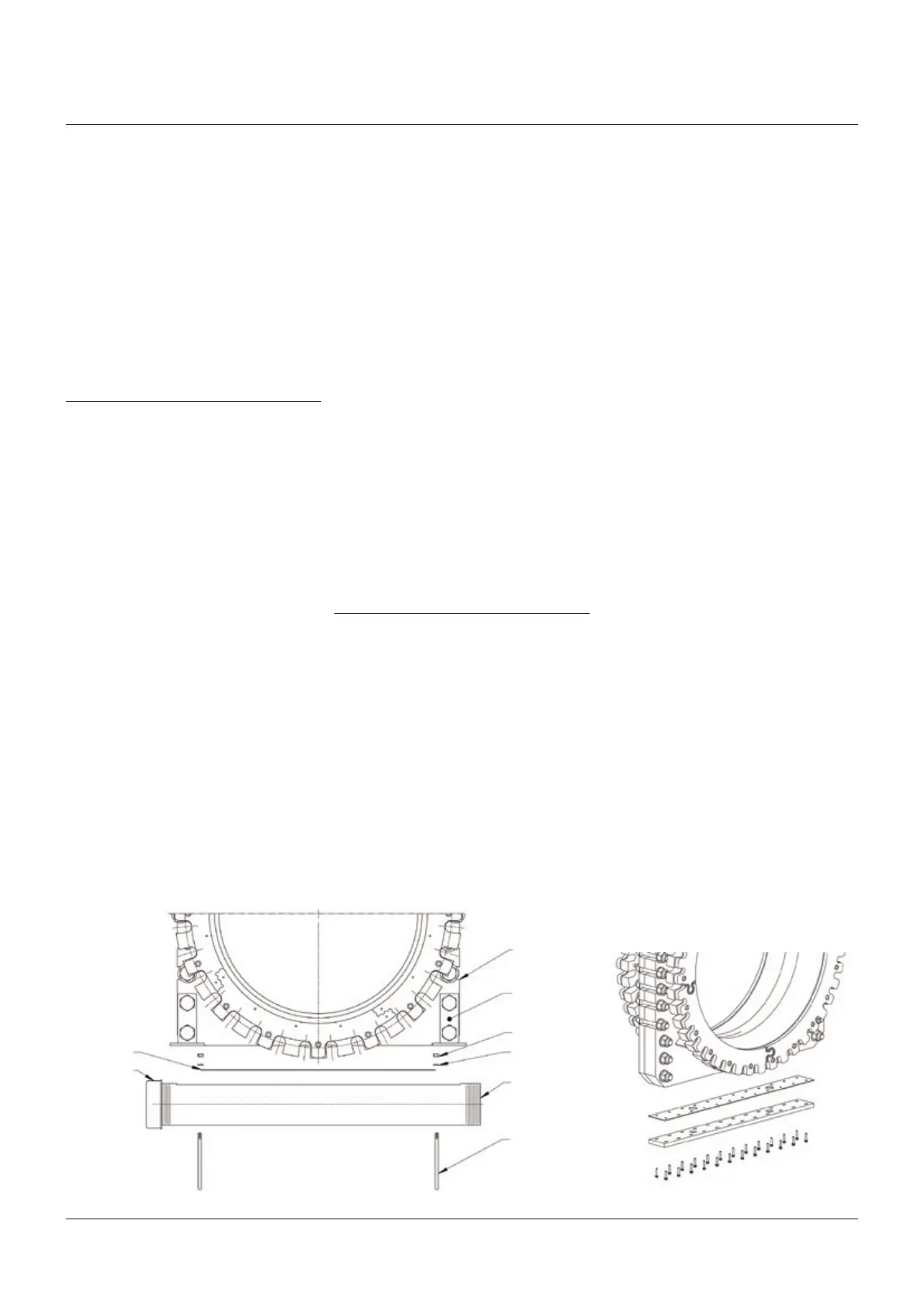

FIGURE 15 FIGURE 16

Gasket

Cap

(one only, do

not cap both

ends)

13 INSTALLATION INSTRUCTIONS FOR

SPLASH GUARD (B7 OPTION)

1. Remove the splash guard, mounting

hardware, and gasket from the valve crate.

Verify that the proper number of mounting

U-bolts, washers, nuts, along with the

guard, end cap, and gasket material are

present.

2. Cut the gasket material into four pieces

that will form the rectangular dimensions

of the bottom of the valve if adhesive back

strip is used. If the gasket is cut from

sheet elastomer stock, ¼" (6.4 mm) thick

material is recommended. Material should

be compatible with the slurry chemistry.

The material used for the retainer flanges

or sleeves will be suitable for the B7 gasket.

Other choices may be possible. Consult

thefactory for recommendations.

3. Clean the flat machined surface of the

splash guard so that there is no dirt, grit,

grease, or other debris present. Remove

the adhesive backing from the gasket

material and apply to the splash guard on

the machined flat mating surface (adhesive

back strip). If a cut sheet gasket is used, it

should be attached to the splash guard with

an RTV type adhesive compound to hold it

during installation. Attach gasket material

to the flat surface along the edge of the

machined slot.

10. Inspect gate for pieces of rubber. If

significant amount of rubber is present, a

sharp edge(s) on the gate may be causing

seal damage or the gate is extending too

far on the up stroke. The ends of the gate

should be free and the center still engaged.

If the sleeve / gate is misaligned, loosen the

frame actuator bolts and / or adjust the yoke

until the proper position, open and closed,

isobtained.

11. If out of pipeline, reinstall the valve, refer

toLifting, Section 15.

4. Install the pipe cap on one end of the splash

guard.

5. Position the guard below the valve and fit

a U-bolt on each end with the fasteners

loosely attached.

6. Verify the position of the gasket material

and the bottom of the housing and tighten

the installed U-bolts.

7. Tighten all U-bolt fasteners until the gasket

is visually compressed.

WARNING!

Do not cap or close-off both ends of the

splashguard. This can result in valve failure.

14 INSTALLATION INSTRUCTIONS FOR DRAIN

PLATE (B9 OPTION)

1. Using a wire brush / scraper, clean the

bottom of the housing.

2. Check the tapped mounting holes on the

bottom of the valve. Remove any debris or

obstructions from the holes.

3. Position gasket on drain plate and mount

to the valve using provided bolts and

lockwashers.

4. Connect drain piping (if used) to NPT port(s)

as required.

WARNING!

Do not plug or close-off all ports on the drain

plate. This can result in valve failure.

Loading...

Loading...