9

CLARKSON SLURRY KNIFE GATE VALVES

KGA+

Disassembly

1. Before working on the KGA+ valve, verify

that the valve is in the open position. If it

isnot, move it to the open position.

CAUTION

Assure line is not pressurized before removing

valve. Valve assembly and parts may be heavy,

use proper lifting and support techniques.

SeeSection15, Lifting.

2. Remove the valve from the piping.

3. Visually inspect and verify that the sleeve

bore is clear of all debris, scale and

elastomer residue.

4. Remove the retainer flange bolts taking

caution to prevent retainer flanges from

falling free if in vertical position. Remove

theretainer flanges from the valve.

5. For valves with segmented retainer flanges

(see Figure 9), loosen retainer bolts and pull

each individual segment straight up away

from the valve, do not remove more than

one section at a time.

6. Remove the two elastomer sleeves by

simply pulling each sleeve out of the

housing assembly. (Sometimes a putty knife,

large screwdriver or pry bar is necessary to

pry the retainer flange away from the sleeve

and the sleeve from the valve flange.)

Installation

1. Lay valve down in a horizontal position, on

a flat surface. (While it is possible to install

valve sleeves with assembly in vertical

position, this may make it more difficult

to properly align the retainer flanges and

sleeves, especially on larger valves.)

2. Check the bore diameter for unusual or

excessive wear. If found, valve housing

mayrequire replacement.

3. Table 4 shows the maximum / minimum

bore dimensions of a new KGA+ valve, along

with the maximum allowable diameter

figures of a housing affected by wear and

usage. If housing is not within the maximum

allowable range, it is recommended that the

housing be replaced before installing new

sleeves. In some cases, it may be possible to

make minor repairs to the housing in order

to continue using it. Please contact the

factory for information.

4. Lubricate the O.D. of the seal end of

thesleeve.

5. Install the sleeve, being careful to center

theflange end in the bore of the housing.

6. Place a retainer flange on the top of the

sleeve. Align the retainer flange bolt holes

with the matching holes in the round

flange. Align the I.D. of the sleeve and

retainerflange.

7. For valves with segmented retainer flanges,

position one retainer flange segment on the

sleeve lip. Align with proper mounting holes

in the round flange. Install the required

bolts and nuts; hand tight. Position the next

segment on the sleeve lip opposite the one

previously installed. Install fasteners as

before. Continue to install segments in this

manner until complete flange is in position.

8. Install the retainer bolts. Only tighten

sufficiently to allow installation of the

next bolt. Continue this until all bolts

areinstalled.

9. Once all bolts are in place, tighten the

retainer flange bolts using a cross pattern

until there is a 0” - ⅛” (0 - 3 mm) gap

between the retainer flange and the

housing. Do not cycle valve with only one

sleeve in place.

Note: certified Clarkson elastomer parts from

Emerson are laser-etched with part number,

date of manufacture, the Clarkson brand

name and other appropriate information to

assure you have a genuine Clarkson part. The

use of non-OEM parts will void any remaining

warranty.

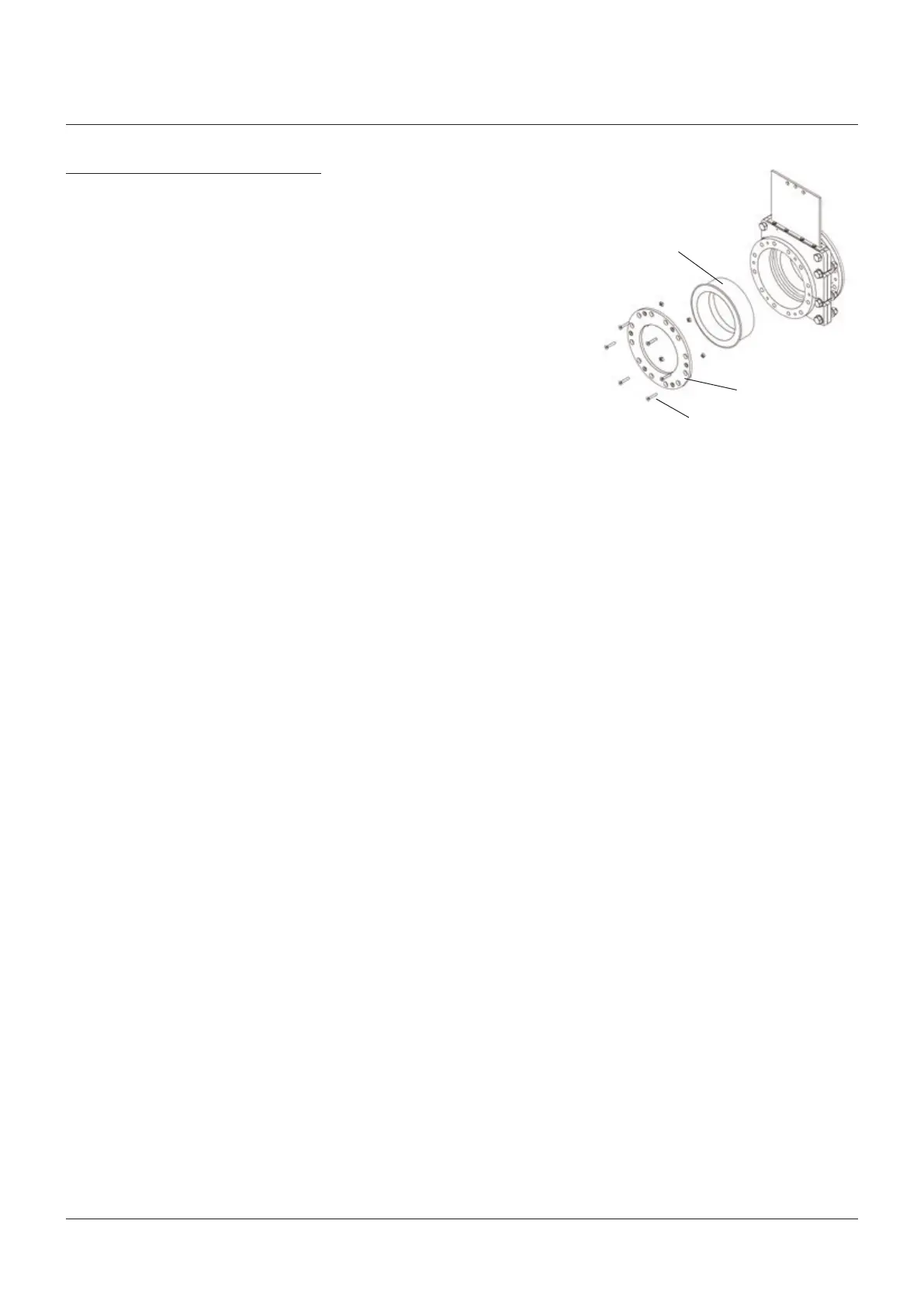

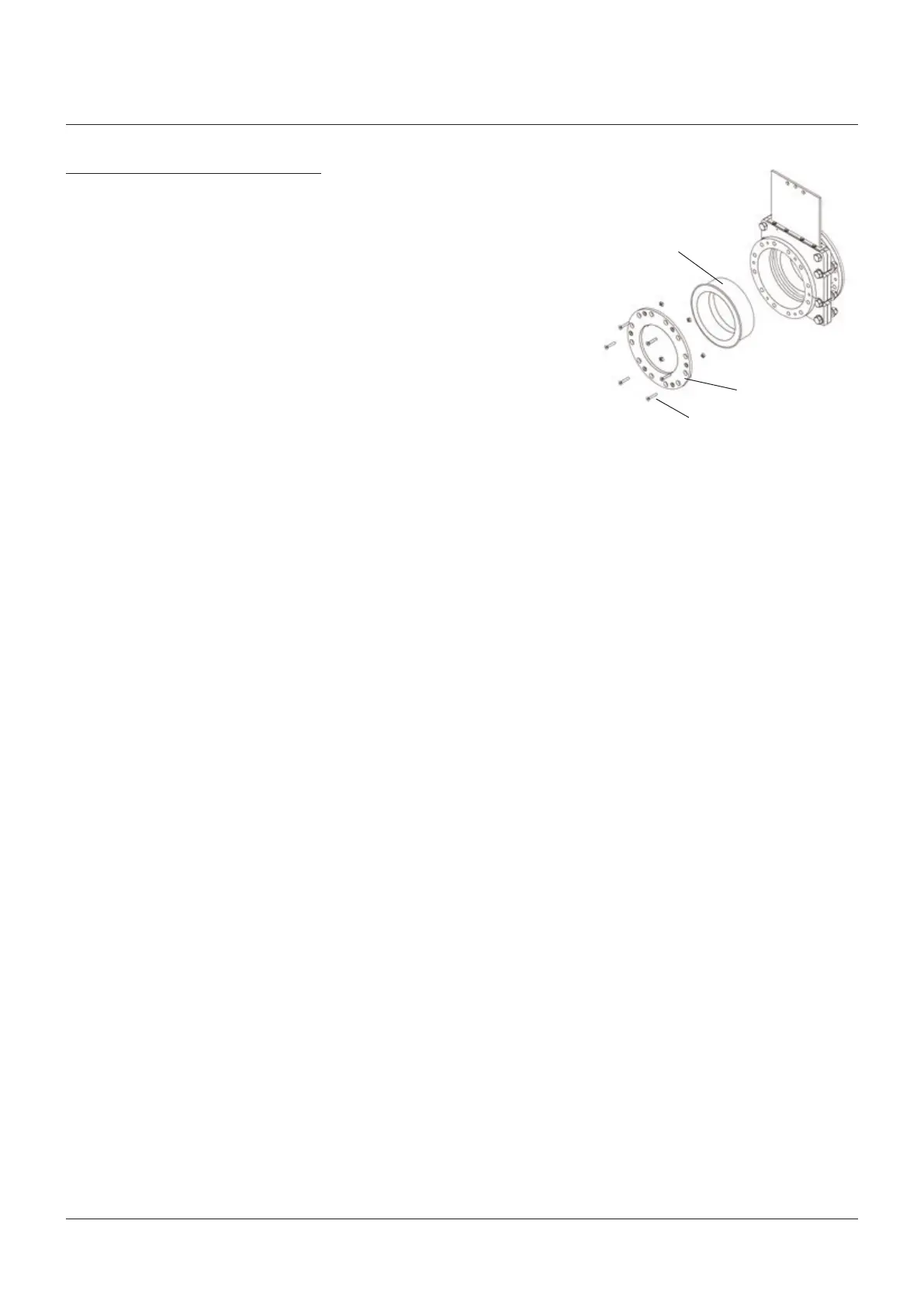

FIGURE 8

Sleeve

Retainer

Retainer bolts/nuts

9 SLEEVE REPLACEMENT

Note: sizes NPS 8 (DN 200) and below may

or may not have the optional retainer flanges.

Retainer flanges are standard on sizes NPS 10

(DN 250) and larger. Larger diameter valves are

supplied with segmented (multipart) retainer

flanges. If your valve has segmented retainer

flanges, take note of the special sections.

Inspection of components

1. Verify that for each valve there are two(2)

sleeves, two (2) retainer flanges (if required),

retainer flange bolts and nuts (if required).

KGA+ NPS 30 - 60 (DN 750 - 1500), use

segmented retainer flanges. Refer to

the Clarkson certified parts list for the

appropriate valve size to determine the

quantity of retainer flange nuts and bolts

required.

2. Visually inspect each sleeve and retainer

flange for damage to surfaces resulting

from shipping or post-shipping handling.

The sealing surfaces (nose) must be free

ofdepressions, slits or gouges.

Loading...

Loading...