Configuration and Use Manual 193

Menu Flowcharts – Model 2500 CIO Transmitters

Diagrams Model 2500 CIOModel 1500 ANDefaults Diagrams Model 2500 CIOModel 1500 ANDefaults Diagrams Model 2500 CIOModel 1500 ANDefaults Diagrams Model 2500 CIOModel 1500 ANDefaults

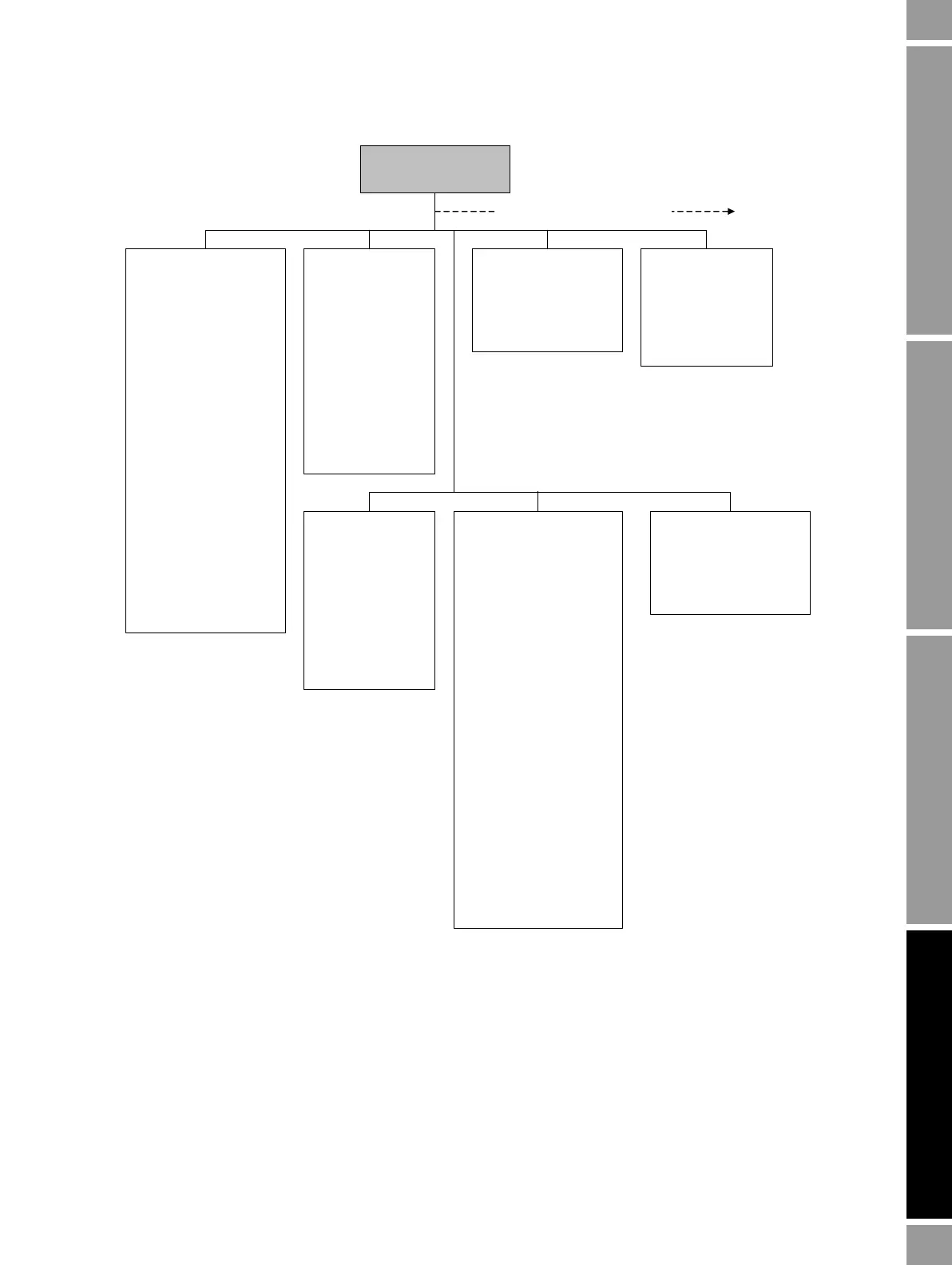

Figure D-2 ProLink II configuration menu

Flow

• Flow direction

•Flow damp

•Flow cal

• Mass flow cutoff

• Mass flow units

• Vol flow cutoff

• Vol flow units

• Vol flow type

• Std gas vol flow cutoff

• Std gas flow units

• Std gas density

Gas wizard

• Mass factor

• Dens factor

• Vol factor

• Enable entrained air

handling

• Flow switch variable

• Flow switch setpoint

Density

• Density units

• Density damping

• Slug high limit

• Slug low limit

• Slug duration

• Low density cutoff

•K1

•K2

•FD

•D1

•D2

• Temp coeff (DT)

Temperature

• Temp units

• Temp cal factor

• Temp damping

• External temperature

Pressure

•Flow factor

• Dens factor

• Cal pressure

• Pressure units

• External pressure

ProLink >

Configuration

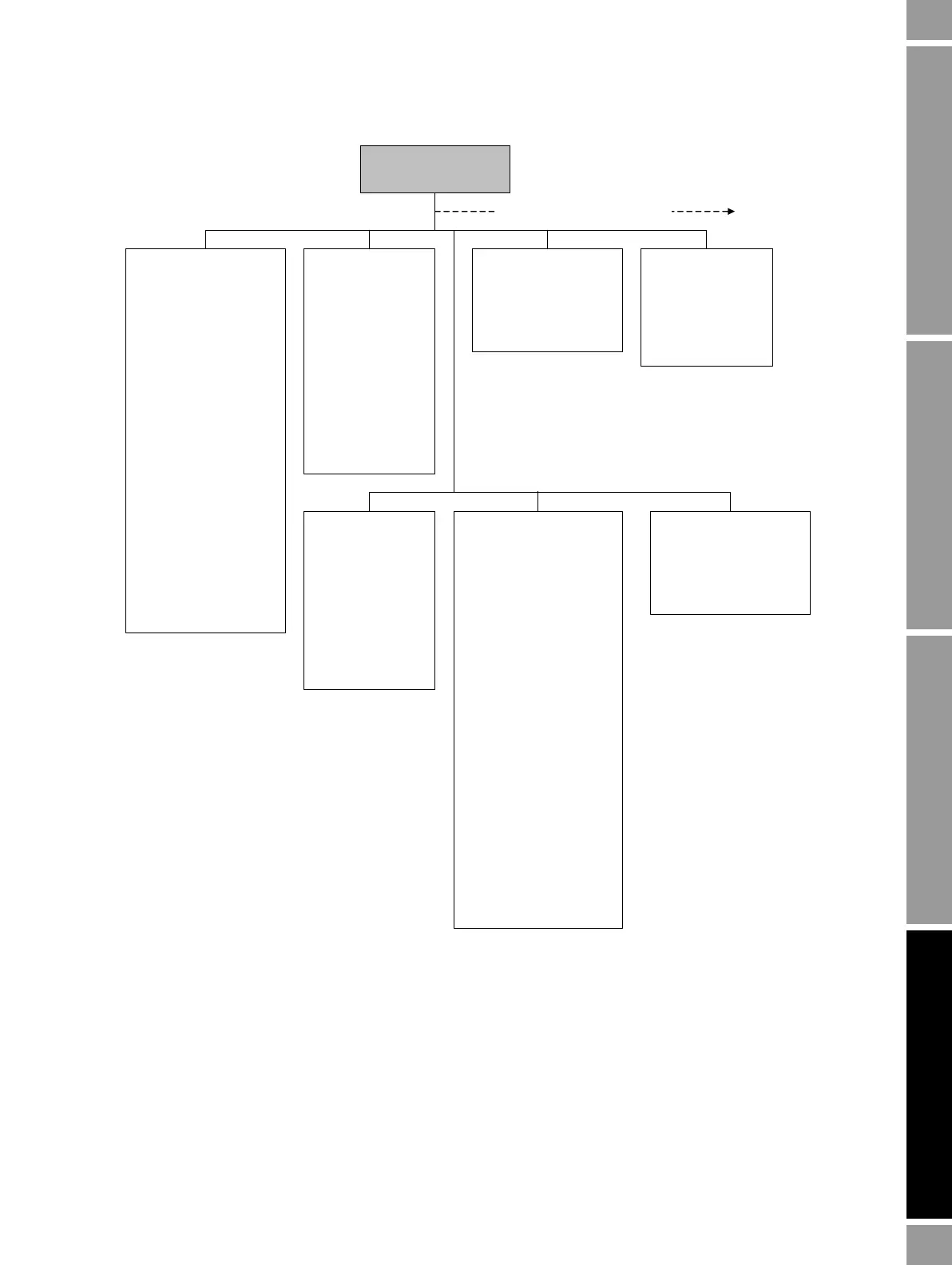

Additional configuration options

Device

•Tag

•Date

• Descriptor

• Message

• Sensor type

• Transmitter serial number

• Floating pt ordering

• Add comm resp delay

Digital comm settings

• Fault setting

• HART address

• Loop current mode

•HART device ID

• Modbus address

• Enable write protection

Update rate

• Update rate

•100 Hz variable

Burst setup

• Enable burst

• Burst cmd

• Burst var 1...4

T Series

•FTG

•FFQ

•DTG

•DFQ1

•DFQ2

•K3

•D3

•D4

•K4

RS-485

•Protocol

•Parity

• Baud rate

• Stop bits

Loading...

Loading...