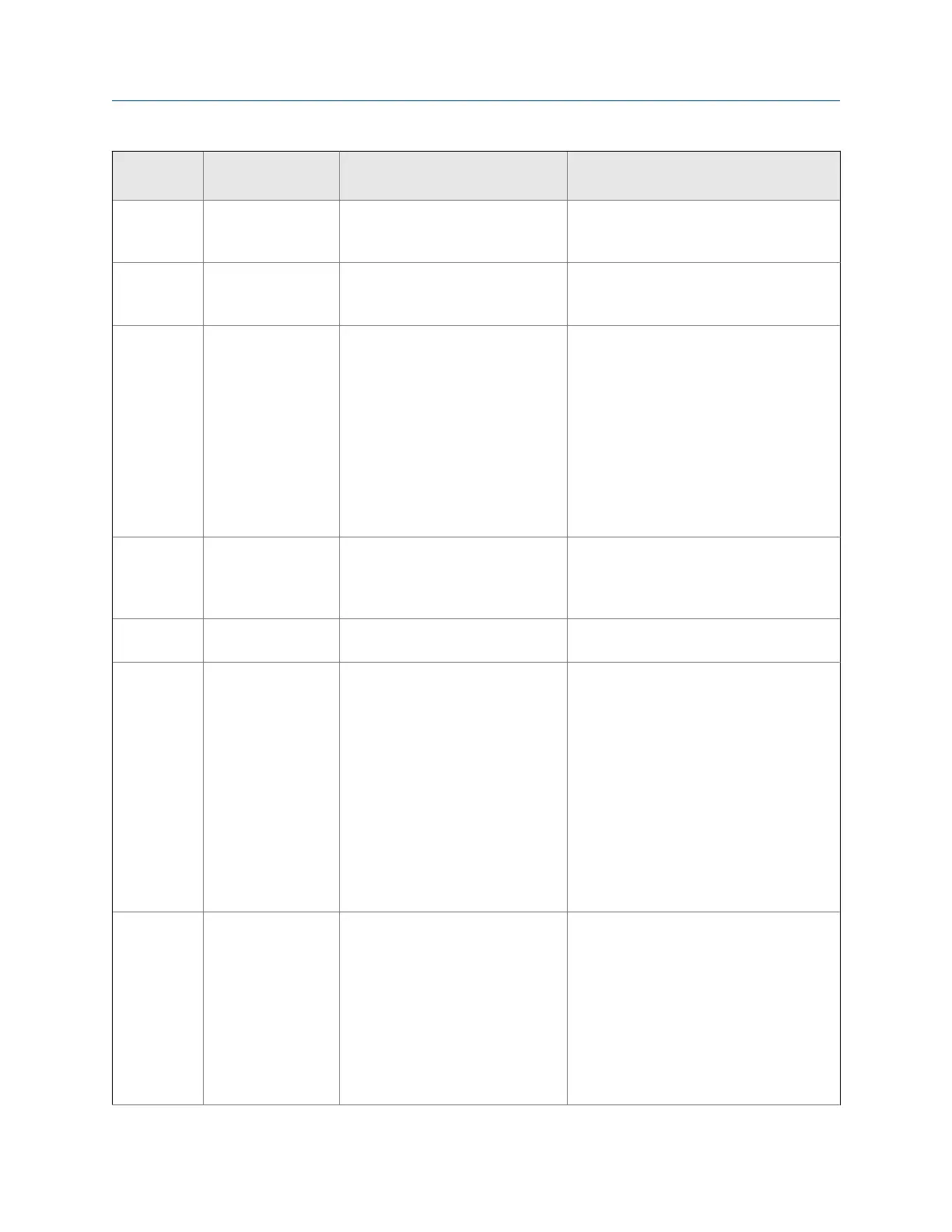

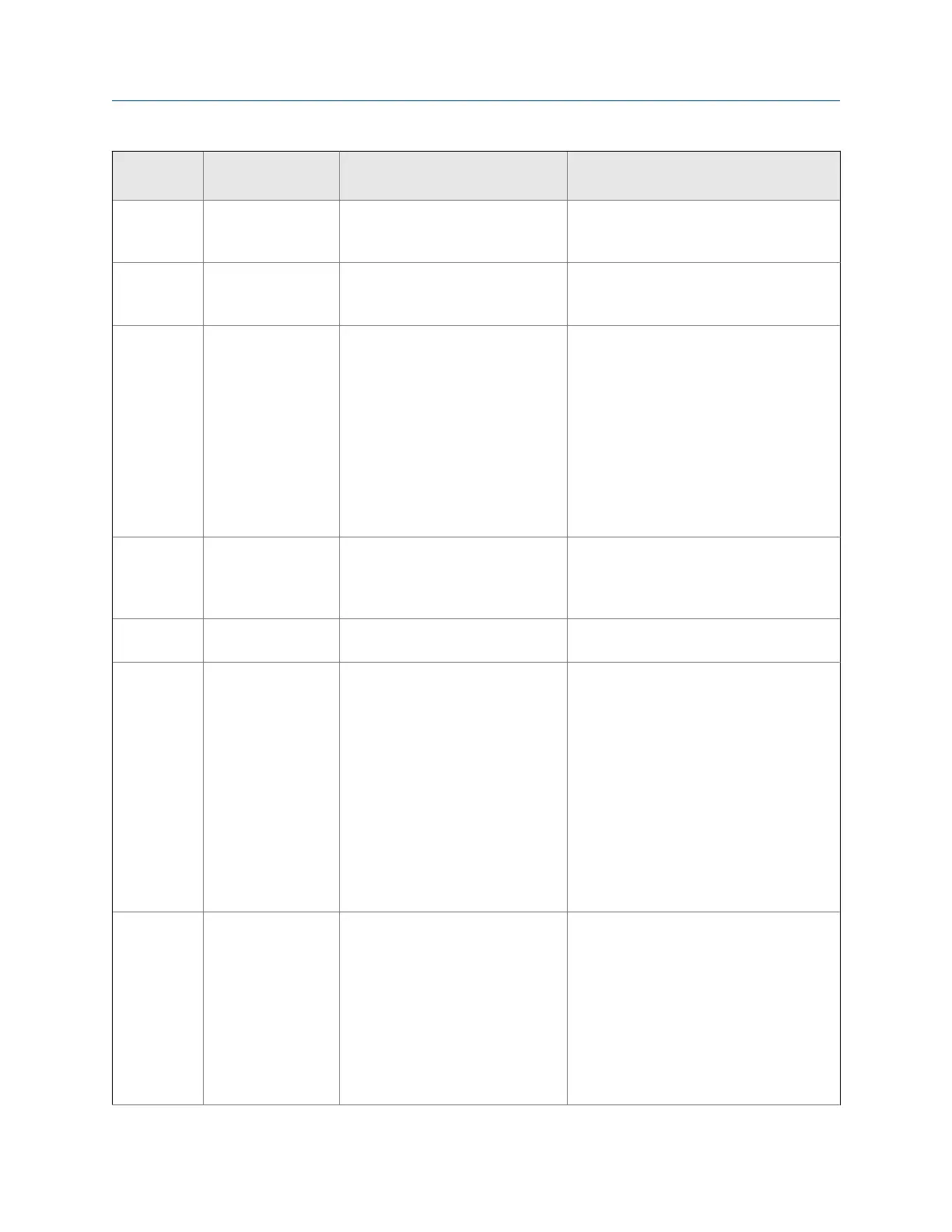

Alert num-

ber Alert title Possible cause Recommended actions

A029 Internal Electronics

Failure

This can indicate a loss of communi-

cation between the transmitter and

the display module.

• Cycle power to the meter.

• Replace the display module.

• Contact Micro Motion.

A030 Incorrect Board Type The loaded software is not compati-

ble with the programmed board

type.

• Contact Micro Motion.

A033 Insufficient Pickoff

Signal

The signal from the sensor pick-

off(s) is insufficient. This suggests

that the sensor tubes or vibrating

elements are not vibrating. This

alert often occurs in conjunction

with Alert 102.

• Check for foreign material in the proc-

ess gas or fluid, coating, or other proc-

ess problems.

• Check for fluid separation by monitor-

ing the density value and comparing

the results against expected density val-

ues.

• Ensure that the sensor orientation is ap-

propriate for your application. Settling

from a two-phase or three-phase fluid

can cause this alert.

A037 Sensor Check Failed Known Density Verification failed. • Check the subtest results and perform

the recommended actions.

• Retry the test.

• Contact Micro Motion.

A038 Time Period Signal

Out of Range

The time period signal is outside the

limits for the sensor type.

• Check your process conditions against

the values reported by the device.

A100 mA Output 1 Satura-

ted

The calculated mA output value is

outside the configured range.

• Check the settings of Upper Range Value

and Lower Range Value. See

Section 10.17.

• Check process conditions. Actual condi-

tions may be outside the normal condi-

tions for which the output is config-

ured.

• Check for foreign material in the proc-

ess gas or fluid, coating, or other proc-

ess problems.

• Verify that the measurement units are

configured correctly for your applica-

tion.

A101 mA Output 1 Fixed The HART address is set to a non-

zero value, or the mA output is con-

figured to send a constant value.

• Check whether the output is in loop test

mode. If it is, unfix the output.

• Exit mA output trim, if applicable.

• Check the HART address. If the HART

address is non-zero, you may need to

change the setting of mA Output Action

(Loop Current Mode).

• Check whether the output has been set

to a constant value via digital communi-

cation.

Troubleshooting

Configuration and Use Manual 143

Loading...

Loading...