Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

36 Mentor MP User Guide

www.controltechniques.com Issue: 3

4.3 AC supply requirements

The standard drive is rated for a nominal supply voltage up to 480Vrms.

An optional rating of 575Vrms is available for size 1 drives.

An optional rating of 575Vrms and 690Vrms is available for size 2 drives.

4.3.1 Supply types

Drives rated for supply voltages of up to 575V (rated up to 210A) and

600V (350A and above), are suitable for use with any supply type i.e.

TN-S, TN-C-S, TT, IT with grounding at any potential i.e neutral, centre

or corner (“Grounded delta”).

Grounded delta supplies >575V are not permitted for drives rated up to

and including 210A. Grounded delta supplies >600V are not permitted

for drives rated 350A and above.

4.3.2 Supply fault current

The maximum fault current level of the supply to all circuits is 100kA

subject to the capability of the semiconductor fuse fitted.

4.3.3 MOV ground disconnect

The facility for disconnecting the jumper (link) between varistors and

ground is provided for special circumstances, where a sustained high

voltage may be present between lines and ground, for example during a

high potential test or in certain situations with IT supplies and multiple

generators. If the jumper (link) is disconnected then the immunity of the

drive to high voltage impulses is reduced. It is then only suitable for use

with supplies having overvoltage category II, i.e. not for connection at

the origin of the low voltage supply within a building.

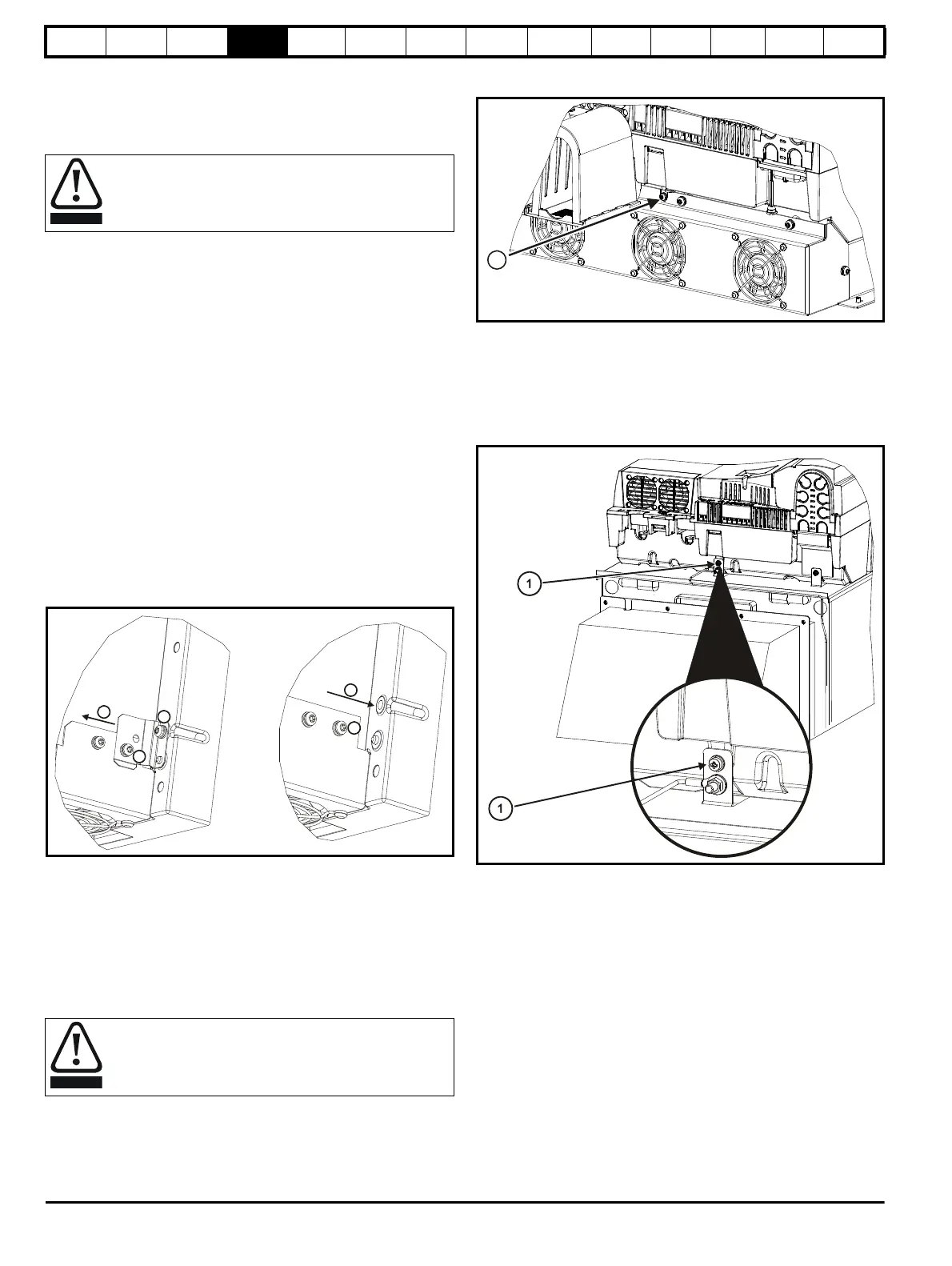

Figure 4-6 Removing the MOV ground connection on size 1 drives

The method for disconnecting the MOV ground connection on size 1

drives is shown below:

1. Remove the M4 x 16 screw using T20 Torx driver.

2. Remove the M4 x 12 screw using T20 Torx driver.

3. Remove the plate.

4. Re-fit the M4 x 12 screw using T20 Torx driver and tighten to a

torque of 0.6 Nm (0.44 Ib ft).

5. Fit a M4 x 16 nylon screw (not supplied) and tighten to a torque of

0.25 Nm (0.18 Ib ft).

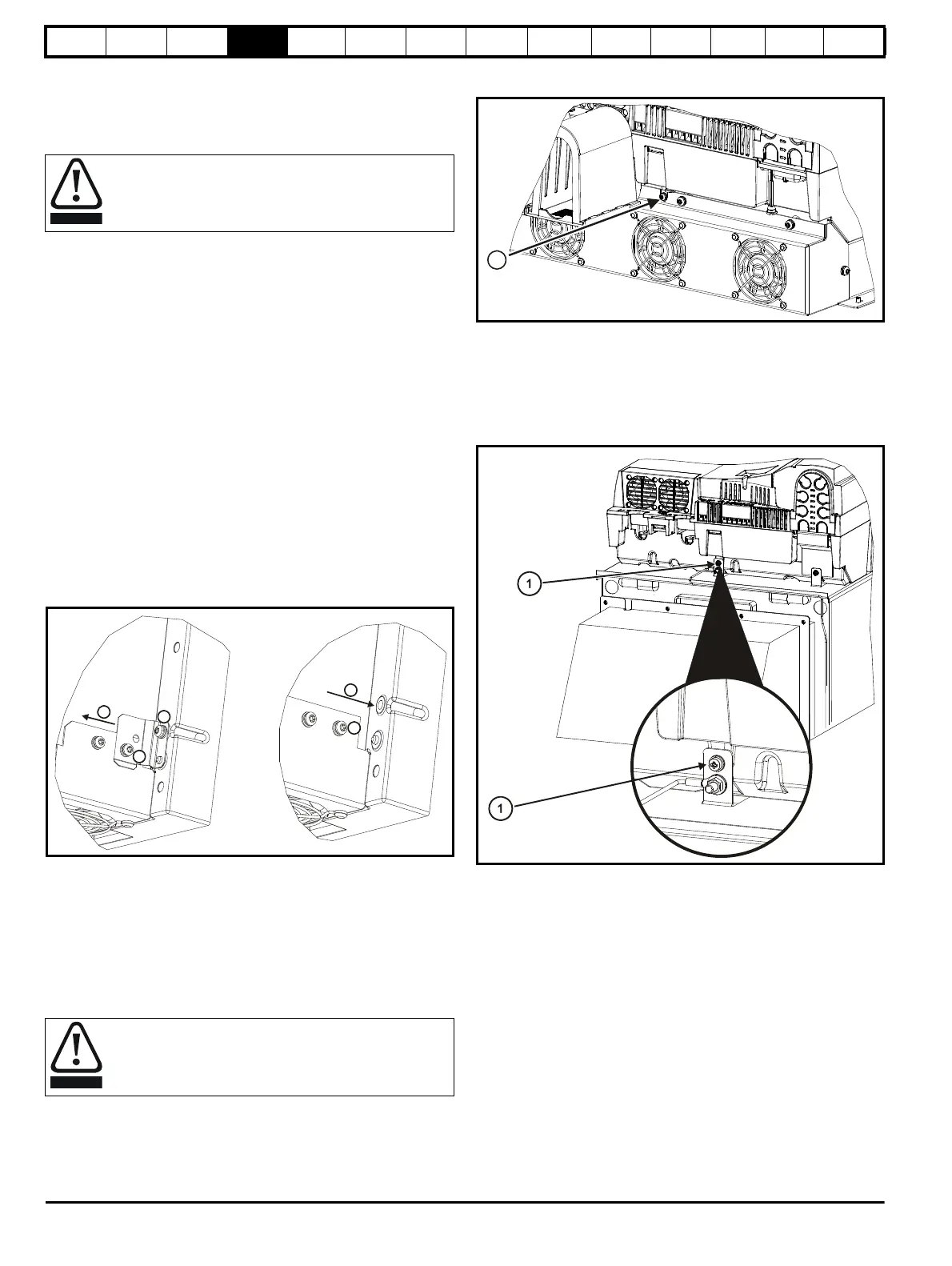

Figure 4-7 Removing the MOV ground connection on size 2A / 2B

drives

The method for disconnecting the MOV ground connection on size 2A /

2B drives is shown below:

1. Remove the M4 x 30 screw using T20 Torx driver .

If re-fitting the M4 x 30 screw using T20 Torx driver, the screw must be

tightened to a torque of 2.5Nm (1.84 Ib ft).

Figure 4-8 Removing the MOV ground connection on size 2C / 2D

drives

The method for disconnecting the MOV ground connection on size 2C /

2D drives is shown in Figure 4-8 above:

1. Remove the M4 x 30 screw using T20 Torx driver .

If re-fitting the M4 x 30 screw using T20 Torx driver, the screw must be

tightened to a torque of 2.5Nm (1.84 Ib ft).

Grounded delta supplies exceeding 575V are not permitted

for drives up to and including 210A. Grounded delta supplies

exceeding 600V are not permitted for drives rated 350A and

above.

The M4 x 16 screw (1) should not be re-used if the plate (3)

is not re-installed. Instead a nylon screw should be used.

Loading...

Loading...