Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Mentor MP User Guide 49

Issue: 3 www.controltechniques.com

If the CT Comms cable is to be used, then pin 6 (TX enable) should be

connected on all drives and pin 4 (+24V) should be linked to at least 1

drive to supply power to the converter in the cable.

Only one CT Comms cable can be used on a network.

4.11 Shield connections

These instructions must be followed to ensure suppression of radio-

frequency emission and good noise immunity in the encoder circuit. It is

recommended that the instructions for the connection of the encoder

cable be followed closely and, to use the grounding bracket and

grounding clamp supplied with the drive, to terminate the shields at the

drive.

4.11.1 Motor cables

Use of a motor cable with an overall shield for the armature and field

circuits may be needed if there is a critical EMC emissions requirement.

Connect the shield of the motor cable to the ground terminal of the motor

frame using a jumper (link) that is as short as possible and not

exceeding 50mm (2in) long. A full 360° termination of the shield to the

terminal housing of the motor is beneficial.

4.11.2 Encoder cable

To get the best results from shielding use cable with an overall shield

and separate shields on individual twisted pairs. Refer to section

4.15 Connecting an encoder on page 54.

4.11.3 Control cables

It is recommended that signal cables should be shielded. This is

essential for encoder cables, and strongly recommended for analog

signal cables. For digital signals it is not necessary to use shielded

cables within a panel, but this is recommended for external circuits,

especially for inputs where a momentary signal causes a change of state

(i.e. latching inputs).

4.11.4 Grounding hardware

The drive is supplied with a grounding bracket, to facilitate EMC

compliance. This provides a convenient method for direct grounding of

cable shields without the use of "pig-tails". Cable shields can be bared

and clamped to the grounding bracket using metal clips, clamps or cable

ties. Note that the shield must in all cases be continued through the

clamp to the intended drive terminal in accordance with the connection

details for the specific signal.

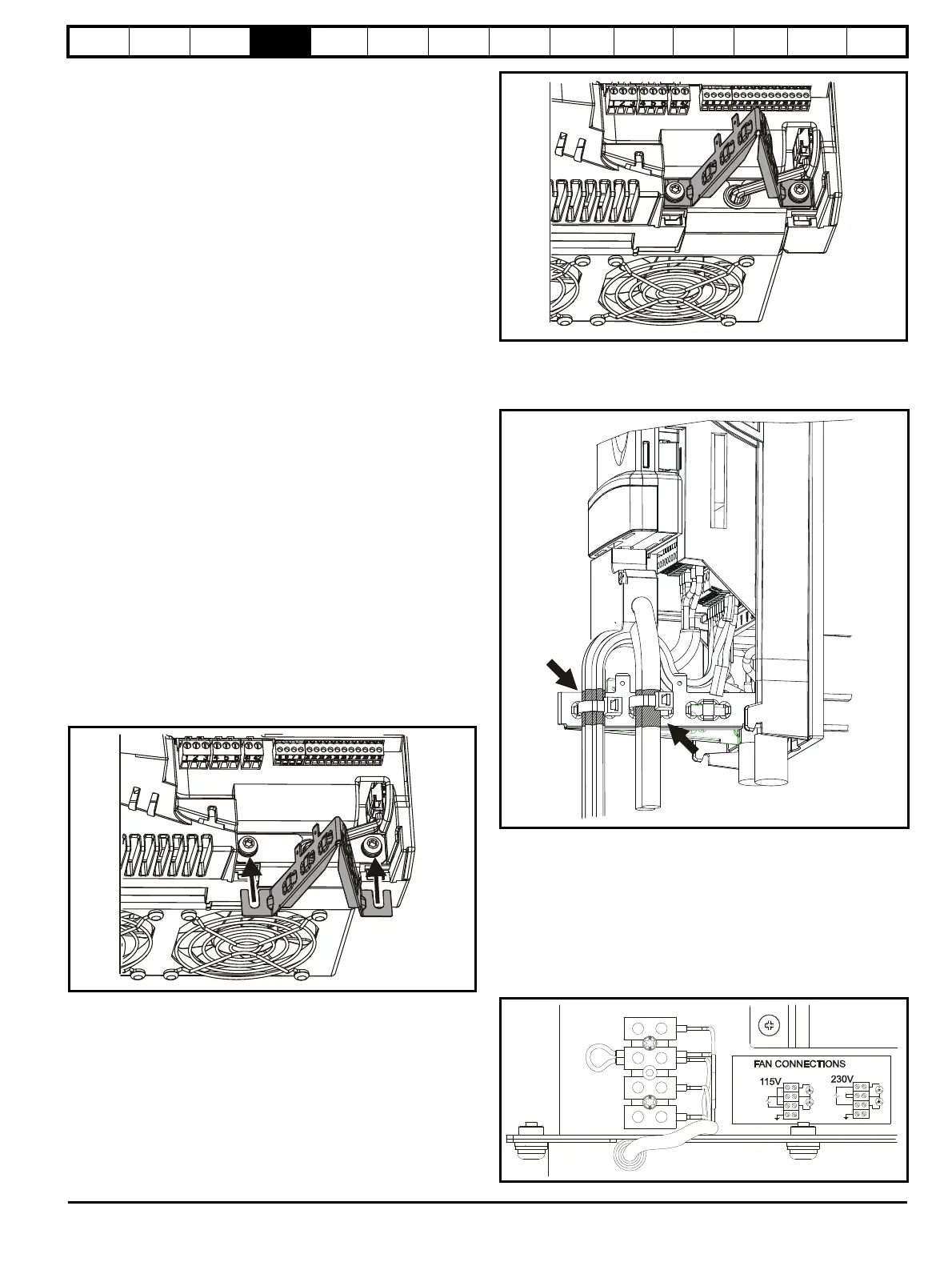

Figure 4-17 Fitting of grounding bracket

Loosen the ground connection (2 x M5 x 10) screws using T25 Torx

driver and slide the grounding bracket in the direction shown. Once in

place, re-tighten the ground connection M5 x 10 screws to 3Nm (2.21 Ib

ft).

A faston tab is located on the grounding bracket for the purpose of

connecting the drive 0V to ground should the user wish to do so.

Figure 4-18 Grounding of signal cable shields using the

grounding bracket

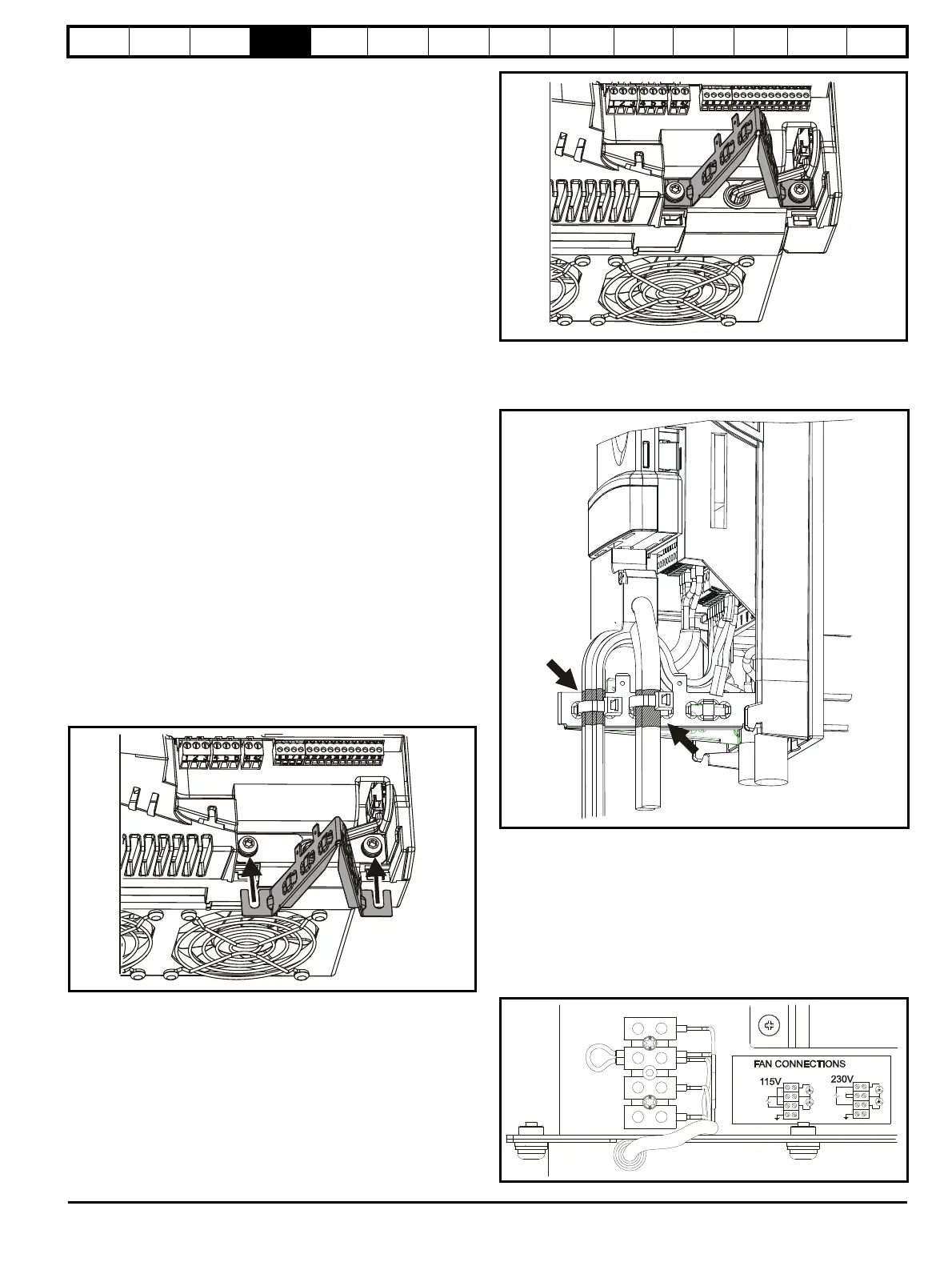

4.12 Connecting the fan on size 2C and 2D

drives

A supply needs to be connected to the dual fan unit enclosed within the

lower duct on Mentor MP size 2C and 2D. The fans can be configured

for a 230Vac (factory setting) or 115Vac supply as shown below on the

label next to the fan connections. When connecting the fan supply, the

screws should be tightened with a maximum torque of 1.2 Nm (0.88 Ib ft)

to 2 Nm (1.47 Ib ft).

Figure 4-19 Fan connection

Loading...

Loading...