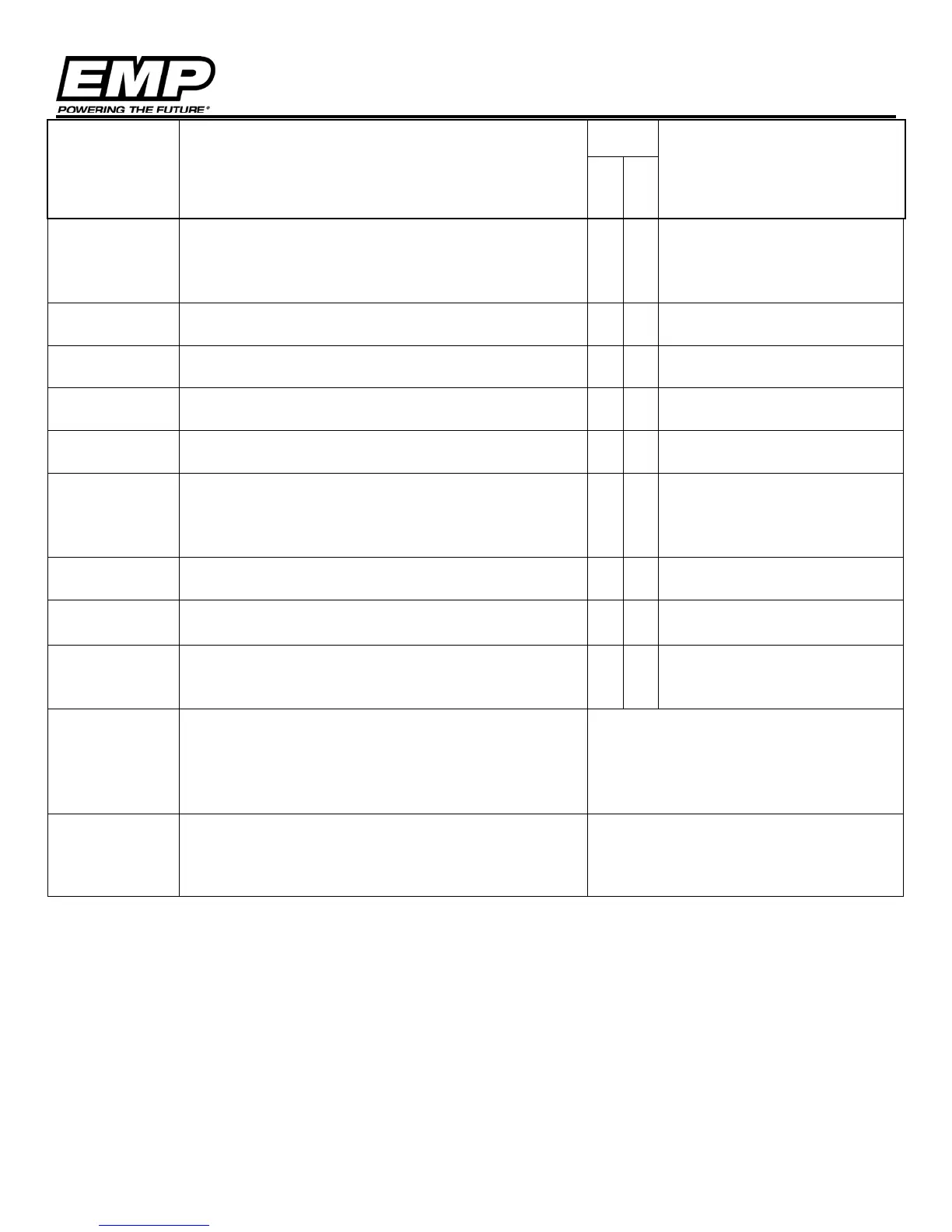

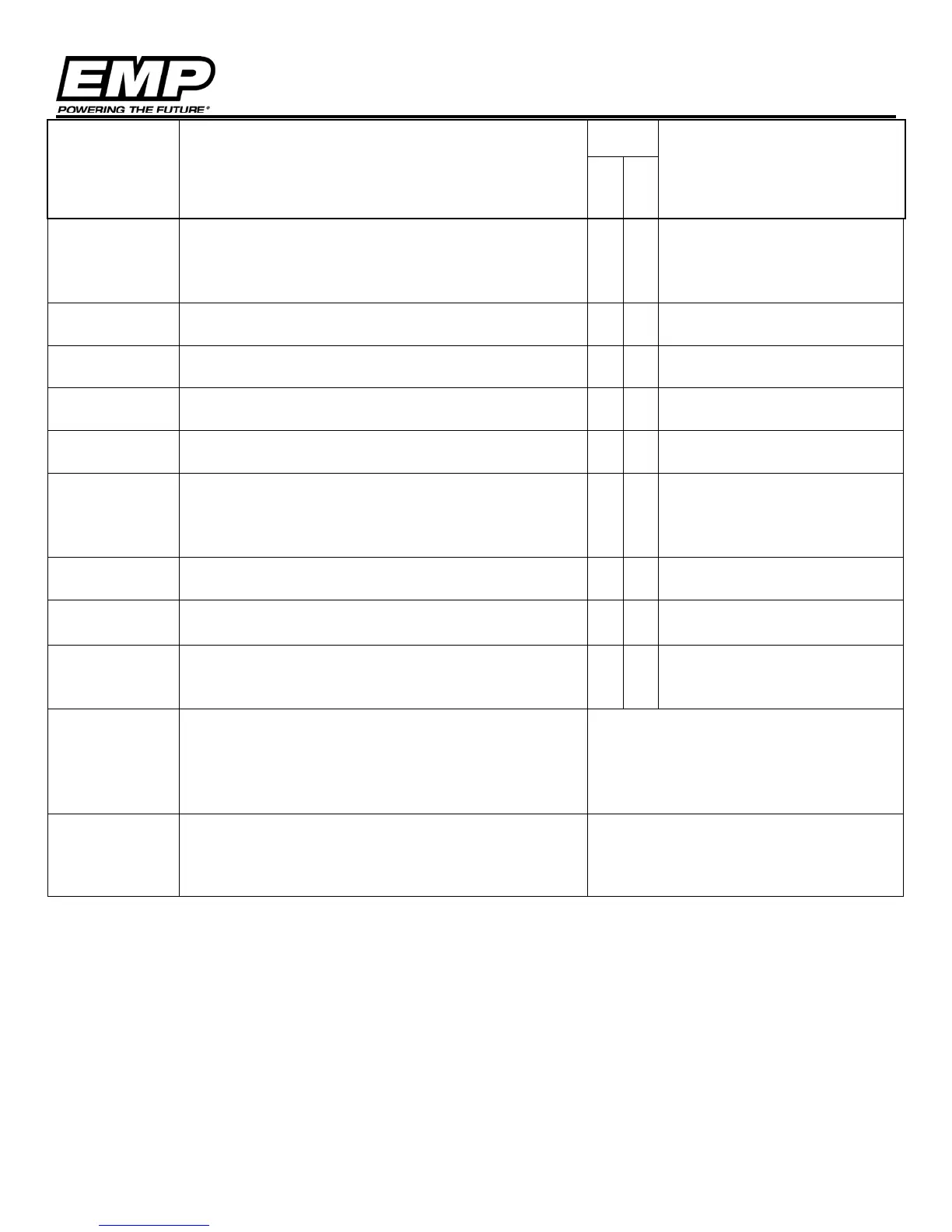

Appendix B, EMPower Connect Service Tool

© 2013 EMP, Inc 29

Reference Document(s)

and/or

Comments

Reference

Section

Input Requirement

Yes

No

Plumbing

Are there any elevated areas in the inlet supply?

NOTE: Areas where air can be trapped and prevent

coolant flow to the pump. The WP29 and WP32 is not a

self-priming pump.

Plumbing

Is the WP29 and WP32 more than 6 inches below the

low fluid level?

Plumbing

Is the inlet pressure greater than -5psig at maximum

operating speed?

Plumbing

Are there any filters or soft plumbing that could

increase inlet restriction over time?

Mounting

Are proper fasteners M8x1.25 used with lock washers

and flat washers?

Mounting

Do the fasteners have 12.7±1 mm (0.5±0.05 inch)

engagement into the pump?

NOTE: Mounting holes are threaded to 15mm (0.59

inch) depth.

Mounting

Are the fasteners torqued to the 20±2 Nm (15±1.5 ft-

lbs) specification?

Installation -

Fault Codes

Are any J1939 feedback parameters other than motor

speed being used for system diagnostics?

Requirements

Have the environmental limitations and the installation

requirements outlined in 9970002273 been reviewed

and agreed to?

Please describe the systems reaction to a WP29 and

WP32 fault.

(e.g. immediate stop, reduced performance, limited

time to operate, system fault code etc..)

If CAN controlled list the CAN messages used for

diagnostics

Loading...

Loading...