Deltabar S FOUNDATION Fieldbus Commissioning

Endress+Hauser 33

Closed containers with superimposed steam

!

Note!

• All Deltabar S versions are suitable for level measurement in containers with superimposed

steam.

• FMD76 and FMD77: the device is ready for calibration immediately after opening a shutoff

valve (may or may not be present).

• FMD78: the device is ready for calibration immediately.

• PMD70 and PMD75: before calibrating the device, the impulse piping must be cleaned and

filled with fluid. See the following table.

Valves Meaning Installation

1 Fill container to a level above the lower tap.

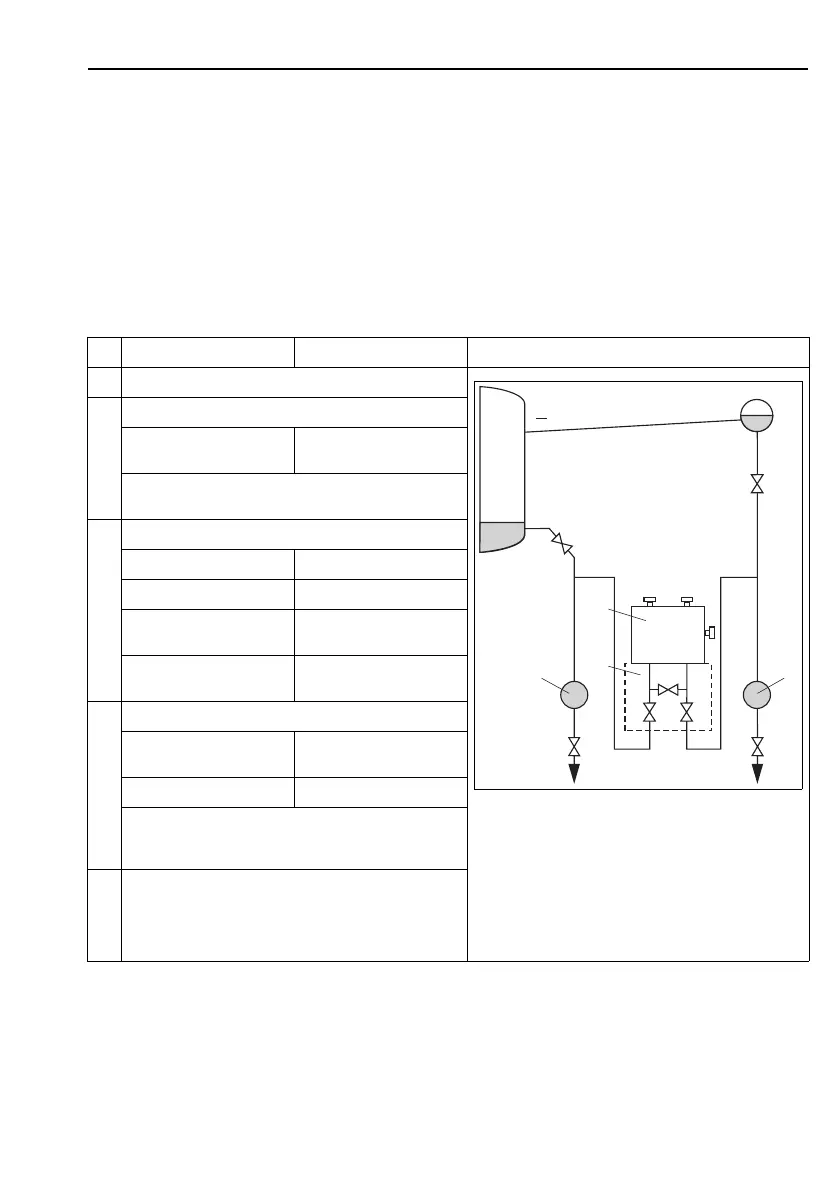

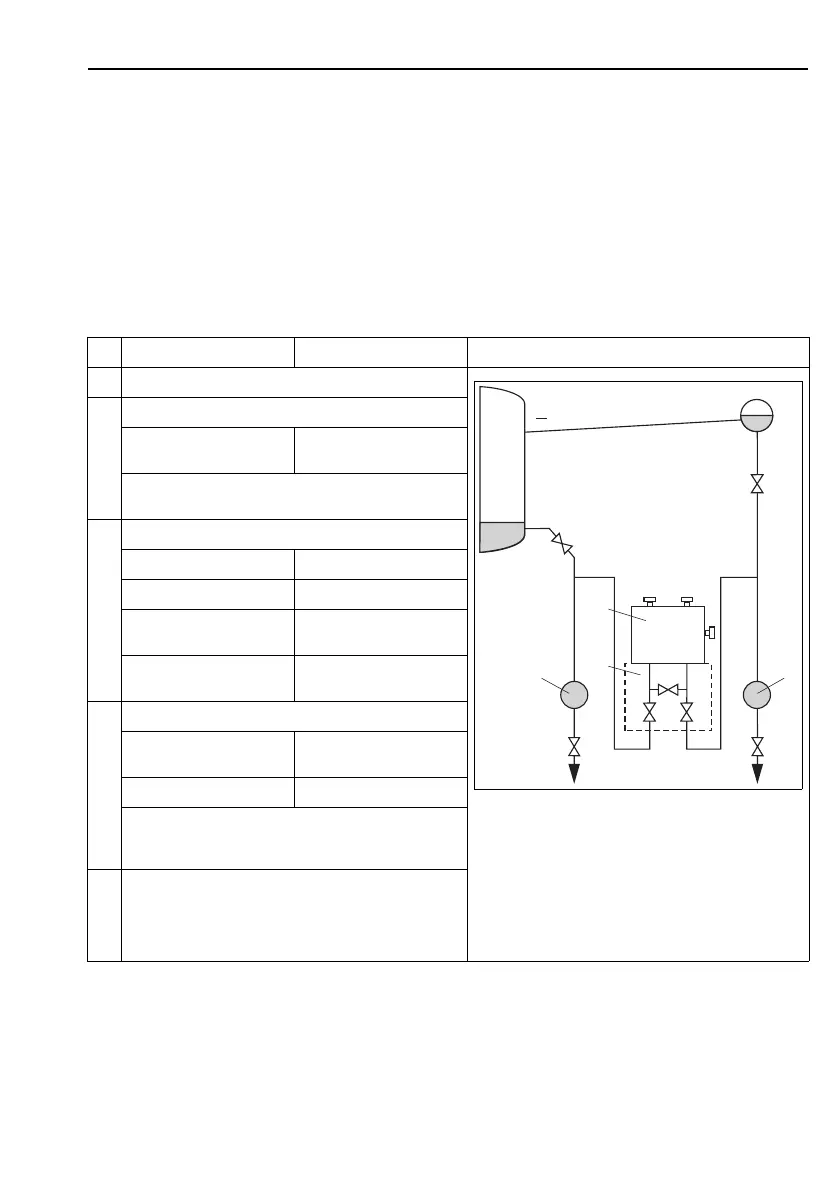

P01-xMD7xxxx-11-xx-xx-xx-005

Fig. 13: Closed container with superimposed steam

I Deltabar S, PMD70 and PMD75

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valves on Deltabar S

A, B Shutoff valves

2 Fill measuring system with fluid.

Open A and B. Open shutoff valves.

Fill the negative impulse piping to the level of the condensate

trap.

3Vent device.

Open 2 and 4. Introduce fluid.

Close 4. Close negative side.

Open 3. Balance positive and negative

side.

Open 6 and 7 briefly, then

close them again.

Fill device completely with

fluid and remove air.

4 Set measuring point in operation.

Close 3. Shut off positive side from

negative side.

Open 4. Connect negative side.

Now

– 3, 6 and 7 are closed.

– 2, 4, A and B are open.

5 Carry out calibration.

See Page 34, Section 6.5.2.

Loading...

Loading...