Liquiphant FTL64

Endress+Hauser 37

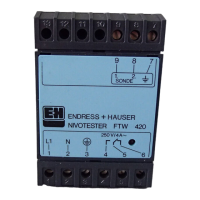

Elements on the electronic

insert

MIN

>0,7

MAX

>0,5

COM

U = 9...20 V DC

4

3 5 8

7

6

L-L+

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

A0037705

46 Example of electronic insert FEL64DC

1 COM interface for additional modules (LED module, Bluetooth module)

2 LED, red, for warning or alarm

3 LED, yellow, switch status

4 LED, green, operational status (device is on)

5 Test button, activates functional test

6 Terminals (3 to 8), relay contact

7 DIP switch for configuring density, 0.7 or 0.5

8 DIP switch for configuring MAX/MIN safety mode

9 Terminals (1 to 2), power supply

Terminals

Terminals for cable cross-section up to 2.5 mm

2

(14 AWG). Use ferrules for the wires.

Local operation Operation at electronic insert

MAX/MIN fail-safe mode

A0033470

47 Switch position on the electronic insert for fail-safe mode MAX/MIN

A MAX (maximum fail-safe mode)

B MIN (minimum fail-safe mode)

• Minimum/maximum quiescent current safety can be switched at the electronic insert

• MAX = Maximum safety: When the tuning fork is covered, the output switches in the direction of

demand. Use this for overfill prevention, for example.

• MIN = Minimum safety: When the tuning fork is uncovered, the output switches in the direction of

demand. Use this for dry-running protection of pumps, for example.

Density switchover

A0033471

48 Switch position on the electronic insert for density

Factory setting for density: 0.7

Loading...

Loading...