EMW90HDNC1A Air-cooled Chiller

5. The refrigerant enters the plate heat

exchanger to evaporate and absorb the heat

of the coolant flowing through the plate heat

exchanger.

6. The circulating pump continuously transports

the coolant to the plate heat exchanger,

exchanges heat with the refrigerant, and

transports the cooled coolant to the container

to cool the battery pack.

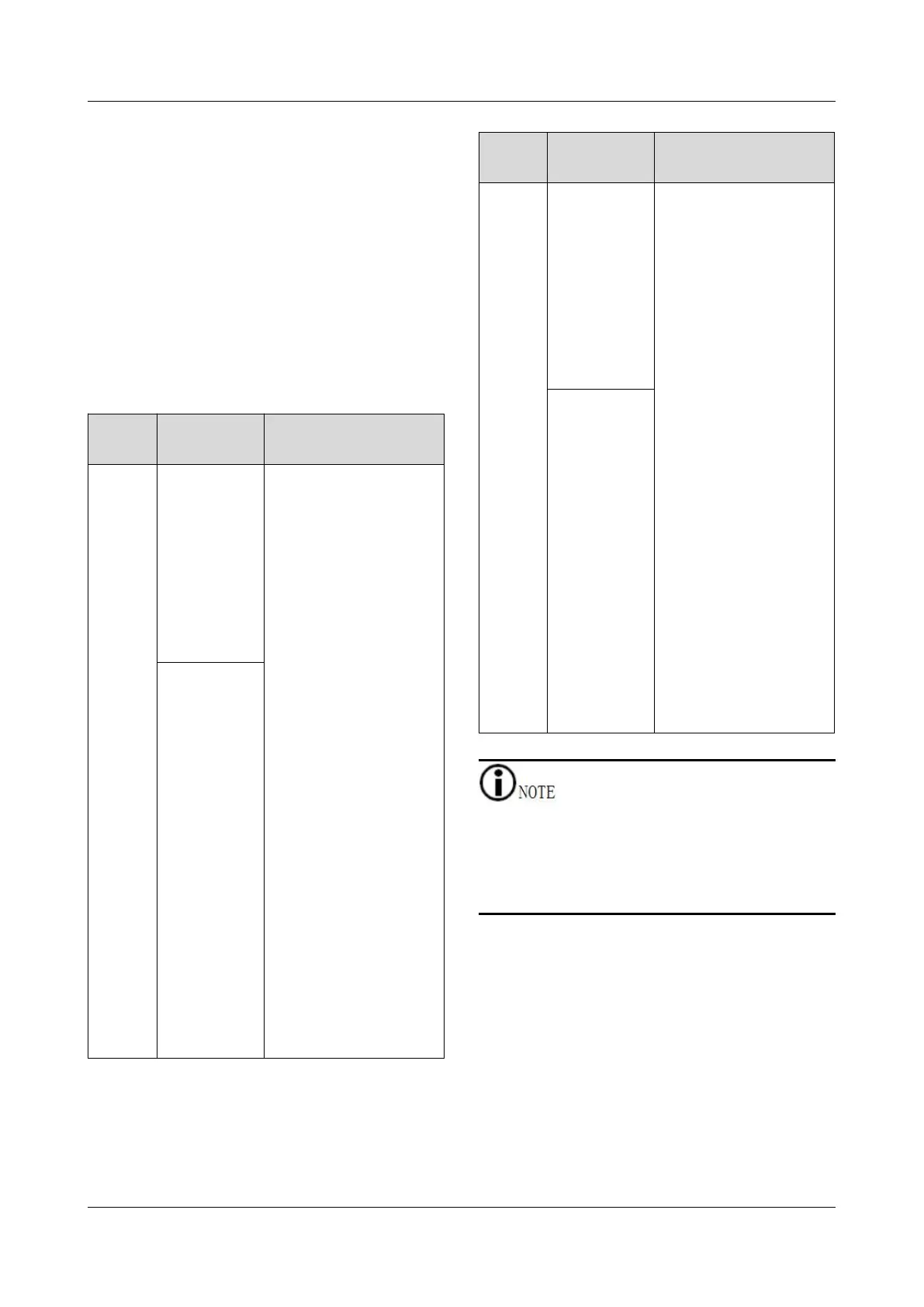

The control logic of EMW90HDNC1A chiller is

shown in Table 2-2.

Table 2-2 Control logic

Refrigeratio

n demand ≥

100%: the

refrigeration

is started.

Refrigeration demand

(%)= (actual control

temperature -

refrigeration set point)

/ refrigeration

sensitivity * 100%

When the refrigeration

set point is 22°C and

the refrigeration

sensitivity is 3°C, the

refrigeration start point

is 25°C

(22°C+3°C*100%=25°

C), and the

refrigeration stop point

is 22°C

(22°C+3°C*0%=22°C)

.

When the outlet

coolant temperature is

used as the actual

control temperature:

coolant temperature

is ≥ 25°C, the chiller

will start cooling.

coolant temperature

is ≤ 22°C, the chiller

stops cooling.

Refrigeratio

n demand ≤

0%: the

refrigeration

is stopped.

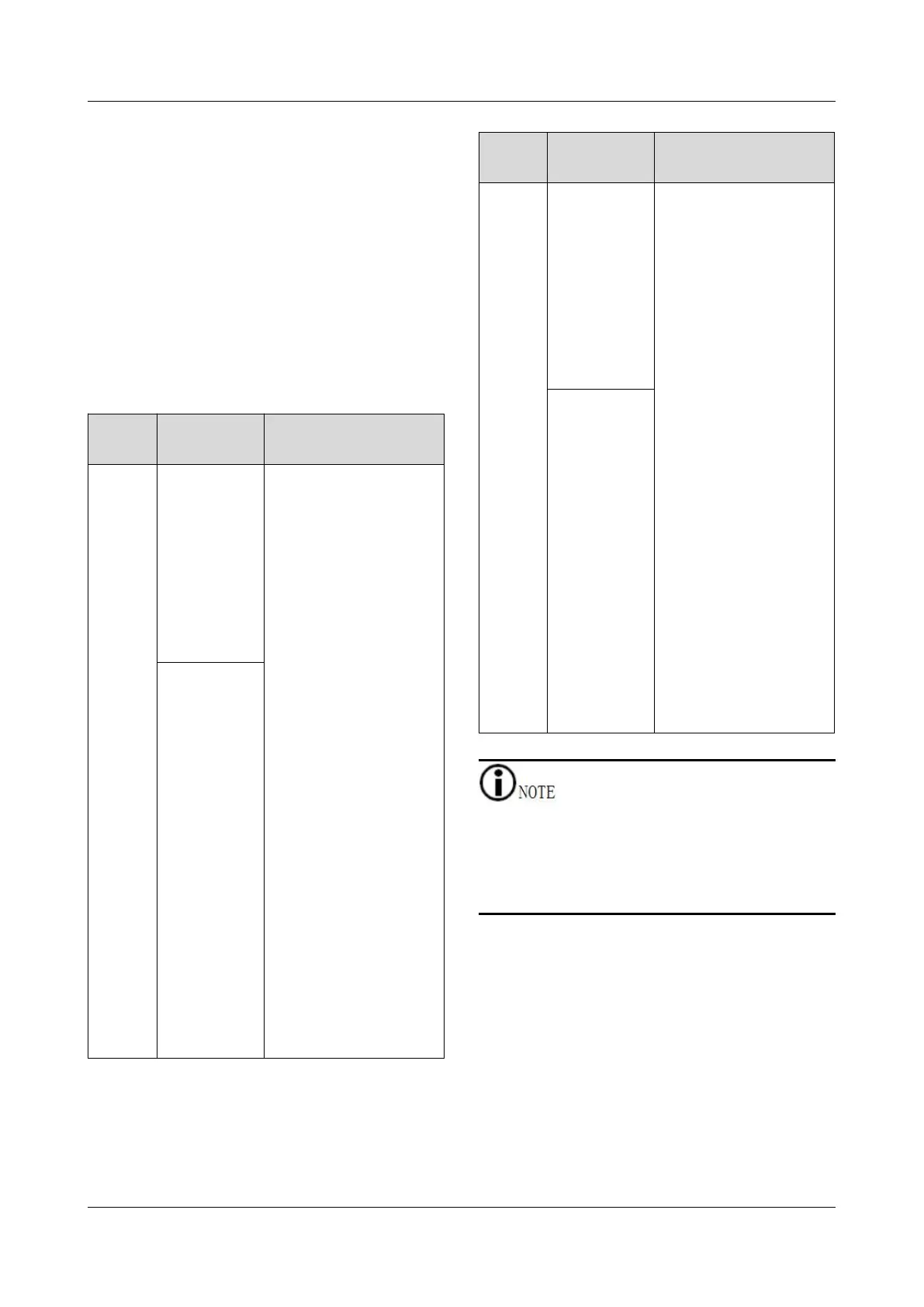

Heating

demand ≥

100%: the

heating is

started.

Heating demand (%)=

(heating set point -

actual control

temperature) / heating

sensitivity * 100%

When the heating set

point is 18°C and the

heating sensitivity is

3°C, the heating start

point is 15°C

(18°C-3°C*100%=15°

C), and the heating

stop point is 18°C

(18°C-3°C*0%=18°C).

When the outlet

coolant temperature is

used as the actual

control temperature:

coolant temperature

is ≤ 15°C, the chiller

will turn on the

electrical heaters.

coolant temperature

is ≥18°C, the chiller

will stop the

electrical heaters.

Heating

demand ≤

0%, the

heating is

stopped.

The actual control temperature is configurable and

supports the coolant outlet temperature and the cell

temperature sent by the host computer.

Refrigeration/heating set point and

refrigeration/heating sensitivity can be configured

according to actual planning.

Loading...

Loading...