EMW90HDNC1A Air-cooled Chiller

The high-efficiency controller is

used to control the cooling

output on demand to achieve

the best cooling and lowest

energy consumption.

conversion compressor and

frequency conversion water

pump to realize double

frequency conversion

adjustment of cooling system

and coolant circulation system.

2.1.2 Function Description

Smart Refrigeration / Heating

The EMW90HDNC1A chiller is equipped with

high-efficiency controller, and supports a field

communicator to visually set control parameters,

which is easy to operate.

The controller monitors the coolant outlet

temperature (the control temperature type is

configurable) in real time, and intelligently adjusts

it according to the target temperature setting, so

that the battery operating temperature in the

container is stabilized within an appropriate

range.

When the coolant outlet temperature is higher

than the refrigeration set point and the

refrigeration start condition is met at the same

time, the chiller starts cooling and chooses to

output different refrigeration capacity

according to the actual temperature.

When the coolant outlet temperature is lower

than the refrigeration set point, the chiller

saves energy by turning off the compressor

and reducing the speed of the circulating

pump.

When the coolant outlet temperature is lower

than the heating set point and the heating start

condition is met at the same time, the chiller

will start electric heater.

RS485 / CAN Communication

The EMW90HDNC1A chillers communicate with

the host computer through the RS485 or CAN

(Controller Area Network) interface using Modbus

or CAN protocol. By sending request messages,

the host computer can perform operations such

as remote start-up and shutdown, query the

operating status of the chiller and set control

parameters to realize remote monitoring of the

chiller.

Power-off Memory and Self-start

After the chiller is powered off, it can memorize

the settings before power off, and it can

automatically and intelligently run according to

the memorized settings after the power is turned

on again.

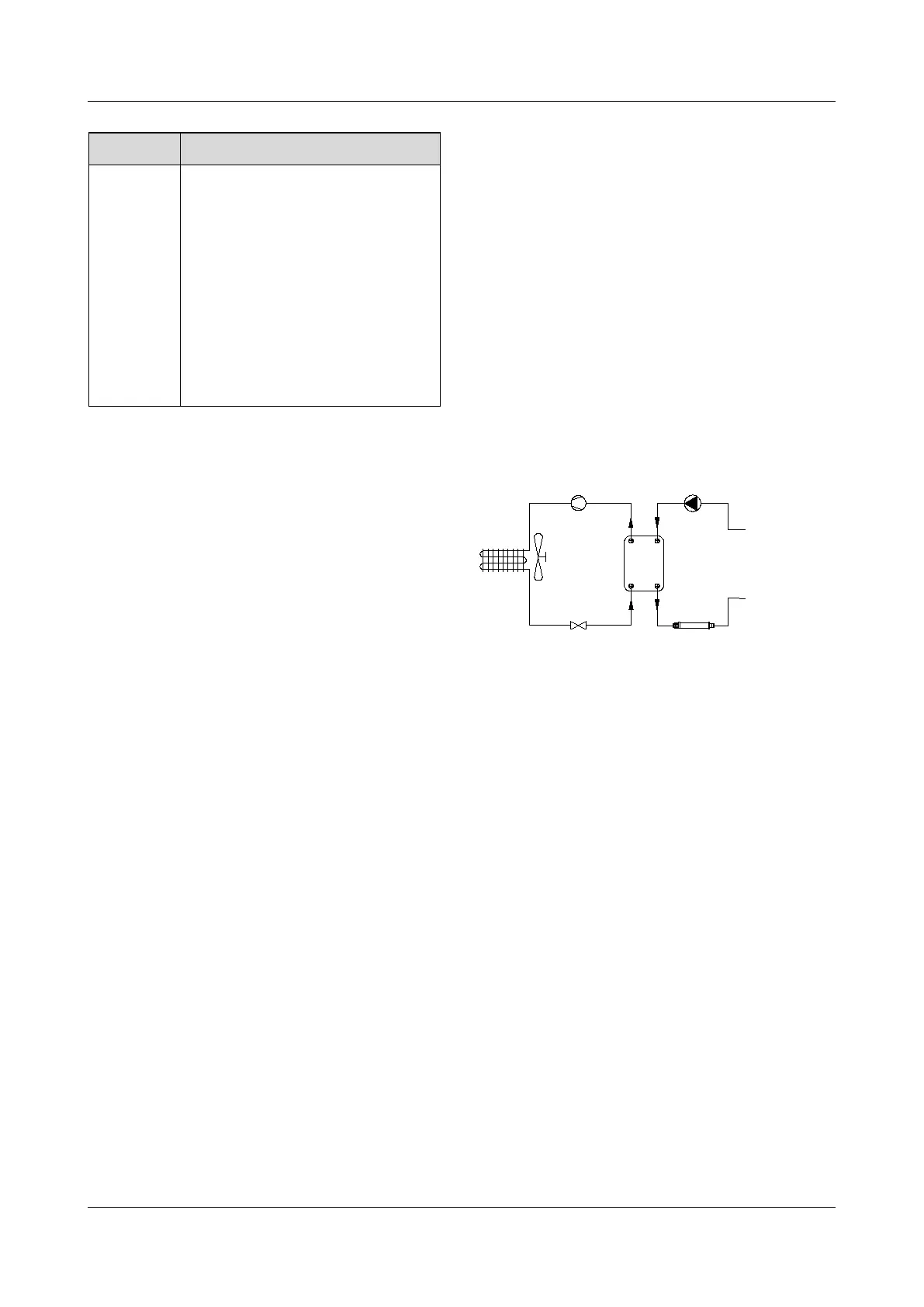

The EMW series chiller is composed of a

refrigeration cycle system and a coolant cycle

system, and the system principle is shown in

Figure 2-2.

Figure 2-2 Chiller composition structure

1

2

3

4

5

7

6

From the load side

To the load side

The working process of EMW series air-cooled

chillers is as follows:

1. When the outlet coolant temperature reaches

the refrigeration opening point, the

compressor starts to compress the gaseous

refrigerant.

The chiller supports the execution of

temperature control logic based on the outlet

coolant temperature and the cell temperature

sent by the host computer.

2. The condenser condenses the

high-temperature refrigerant, and the

refrigerant changes from a gaseous state to

a liquid state.

3. The fan sucks in the outside air and

discharges the heat released when the

refrigerant condenses to the surrounding air.

4. The throttling element (electronic expansion

valve) throttles and depressurizes the

condensed refrigerant.

Loading...

Loading...