Hydraulic Rock Drill COP RR14 / SC14 Ver. C 11 Lubrication

56 No: 4124851851.2.9007203379904011 en-US

• Flow losses in the hydraulic lines are increased. The high flow losses amplify energy

consumption and pressure levels, and put increased strain on seals.

• The risk of cavitation increases, which leads to the risk of damage to the rock drill and

hydraulic pumps.

The hydraulic fluid must be changed at regular intervals

Oil viscosity changes during the period that the hydraulic fluid is used. In general, viscosity

will drop with increased operating hours. To ensure that the viscosity of the fluid does not

drop to a critical level before the recommended service interval, a hydraulic fluid of suffi-

cient stability must be used. In compliance with DIN 51350-6, viscosity of suitable hydraulic

fluids shall drop a maximum of 25% when tested at 100 ºC for shear stability.

Factors influencing the interval between changes are:

• Viscous stability of the hydraulic fluid as specified above. The hydraulic fluid must be

changed before the viscosity drops to a critical level.

• Contamination with water. If the hydraulic fluid becomes cloudy and light grey, the wa-

ter content has become such that the hydraulic fluid must be changed.

• Deterioration of properties such as oxidation inhibition and anti-foaming.

11.1.2 Pneumatic Tool Oil

Pneumatic tool oil is used for cooling and lubricating your rock drill. Depending on ambient

temperature, the oil should have the following viscosity grades if the viscosity index (VI) is

about 100:

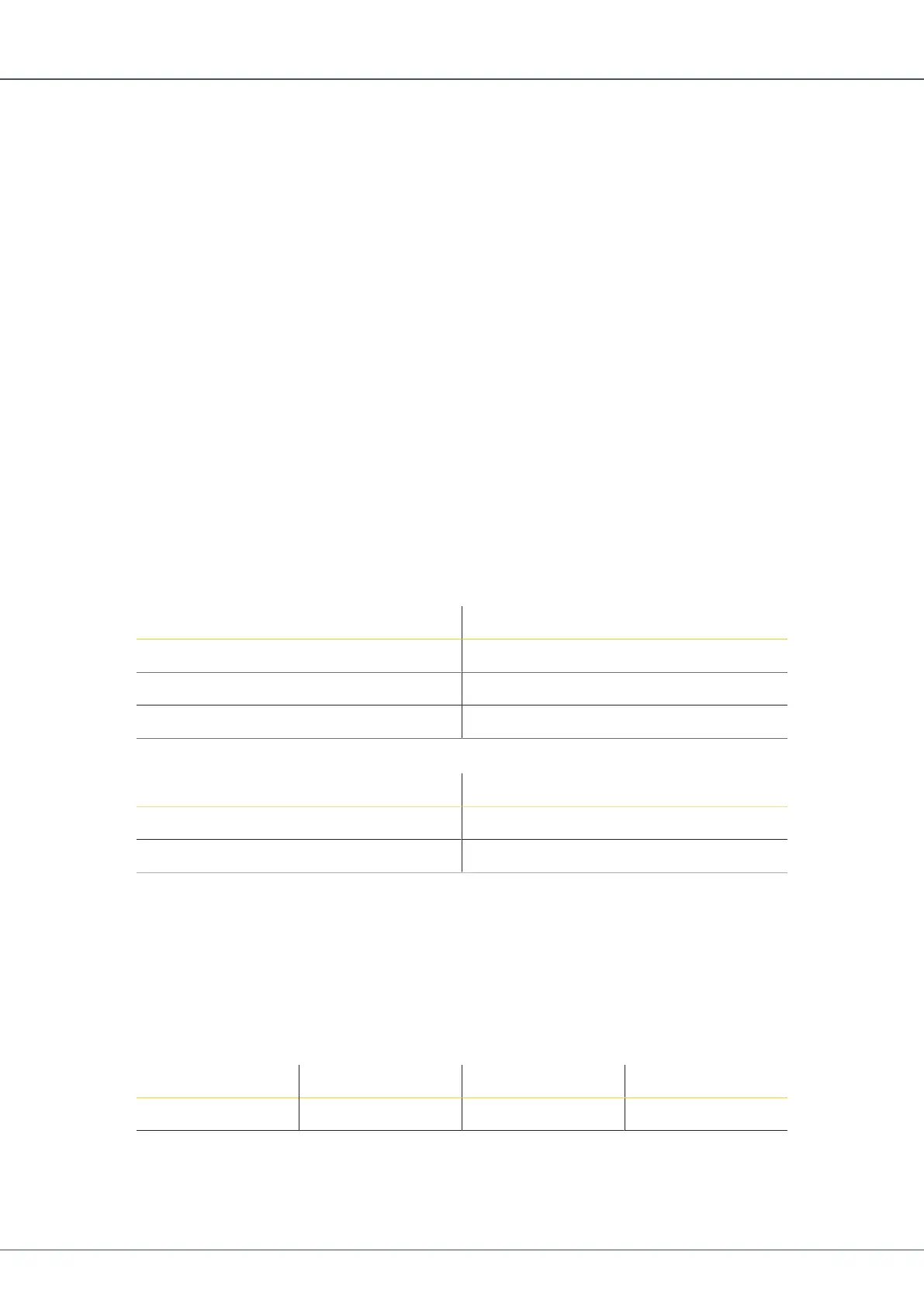

Ambient Temperature C° Viscosity

-30 to ±0 VG 32-68

-10 to +20 VG 68-100

+10 to +50 VG 100-150

The tool oil must have an EP additive which covers the following load-bearing properties:

Referenced Standard Load-Bearing Property

ASTM D 2783 Min. 250 kg

ASTM D 4172 (40 kg) Max. 0.5 mm

The tool oil should also have the following properties:

• The oil must have good lubricating properties, intended for compressed air tools.

• The oil must have good adhesion capacity.

• The oil must have additives that prevent foam formation.

Epiroc recommends the use of Epiroc COP OIL which has been specially developed for

our hydraulic rock drills. COP OIL is an environmentally friendly, biodegradable oil, which

can be used in ambient temperatures between -25 ºC and +50 ºC. COP OIL can be or-

dered with the following part numbers:

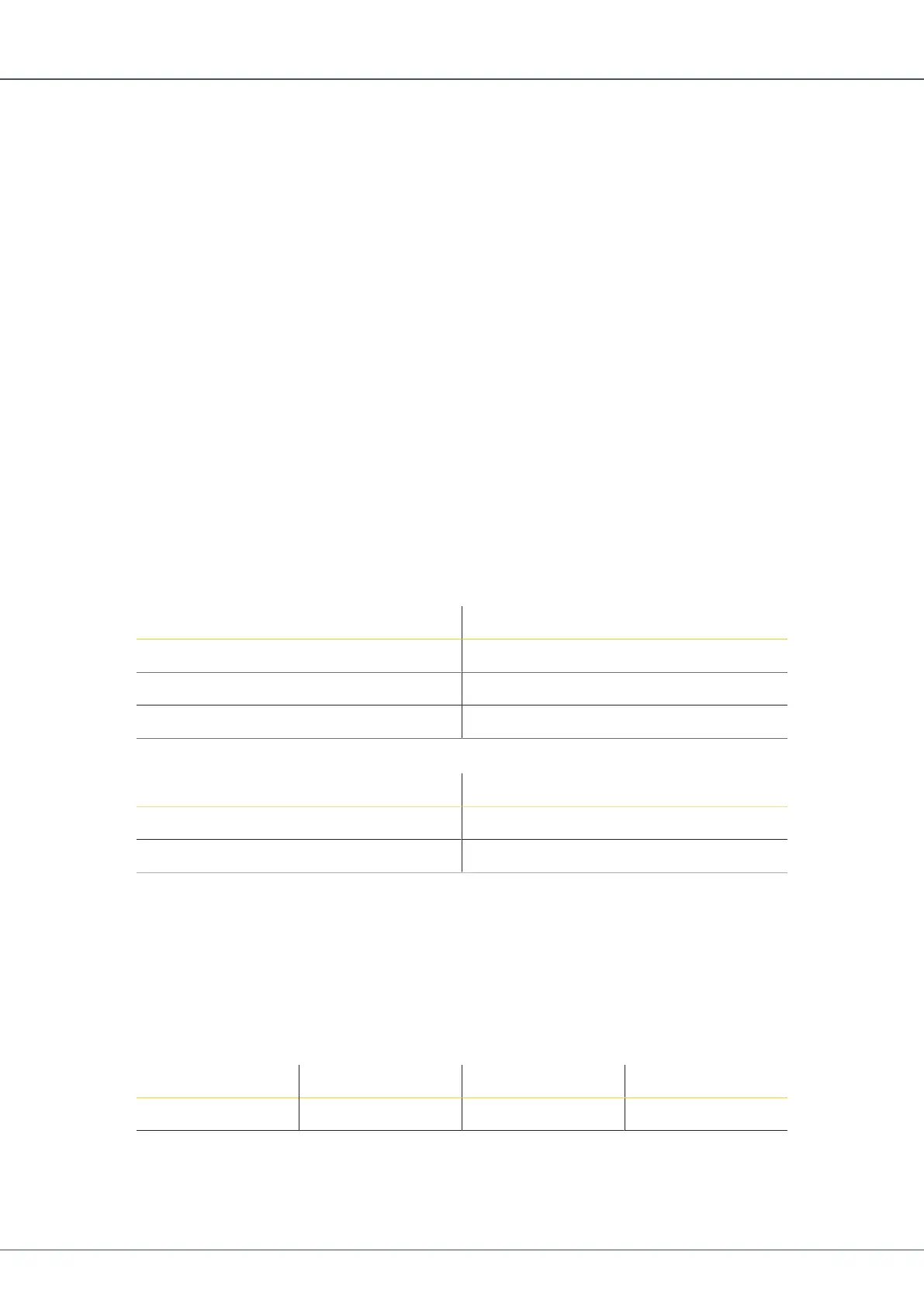

1 Can of 4 litres 1 Can of 20 litres 24 Can of 20 litres 1 Barrel of 208 litres

3115 3125 02 3115 3125 01 3115 3126 01 3115 3127 00

Loading...

Loading...