Hydraulic Rock Drill COP RR14 / SC14 Ver. C 11 Lubrication

57 No: 4124851851.2.9007203379904011 en-US

11.1.3 Grease

Considering the high operating temperature in the rock drill gear housing, always use a

high-temperature grease with lithium complex soap based on a synthetic base fluid (polyal-

phaolefin/synthetic ester) with EP additive, and additives that protect against oxidation, cor-

rosion and wear at high loads. The grease should meet the specifications, specified in the

table below:

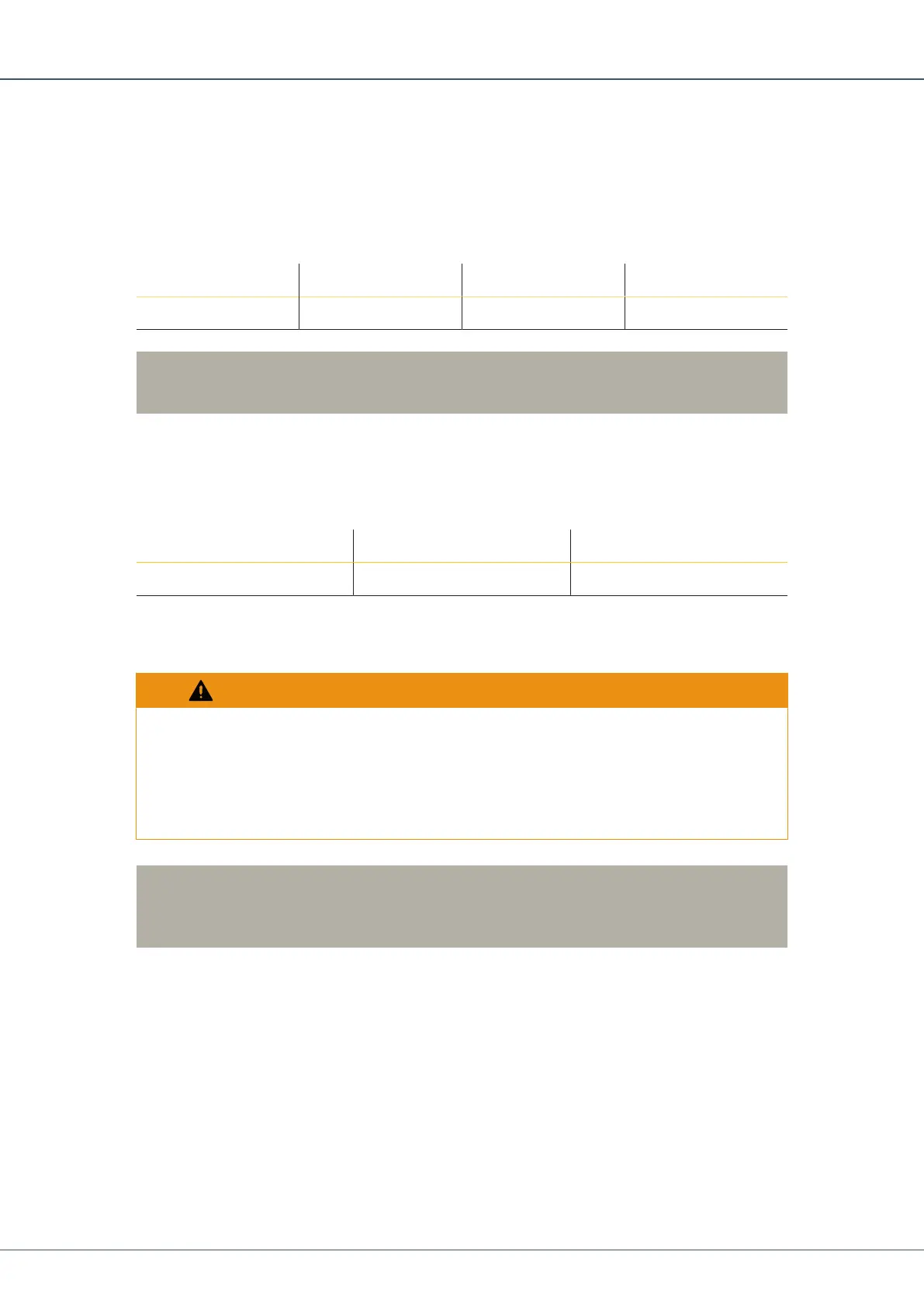

NLGI Number Drop Point Base Oil Viscosity Operating Temp

2 260 °C 220 cSt at 40 °C -15 to +150 °C

!

NOTE: Molybden (Molybden disulfide) grease is harmful for seals. Molybden grease

shall be avoided.

Epiroc recommends the use of Epiroc COP GREASE, which has been specially developed

for our hydraulic rock drills, and is suitable to be used in both gear housing and flushing

seals. COP Grease withstands temperatures between -40ºC to +150ºC, and temperatures

of up to 220ºC during shorter periods. COP Grease is developed to be implemented in

both arctic and tropical conditions, and can be ordered with the following part numbers:

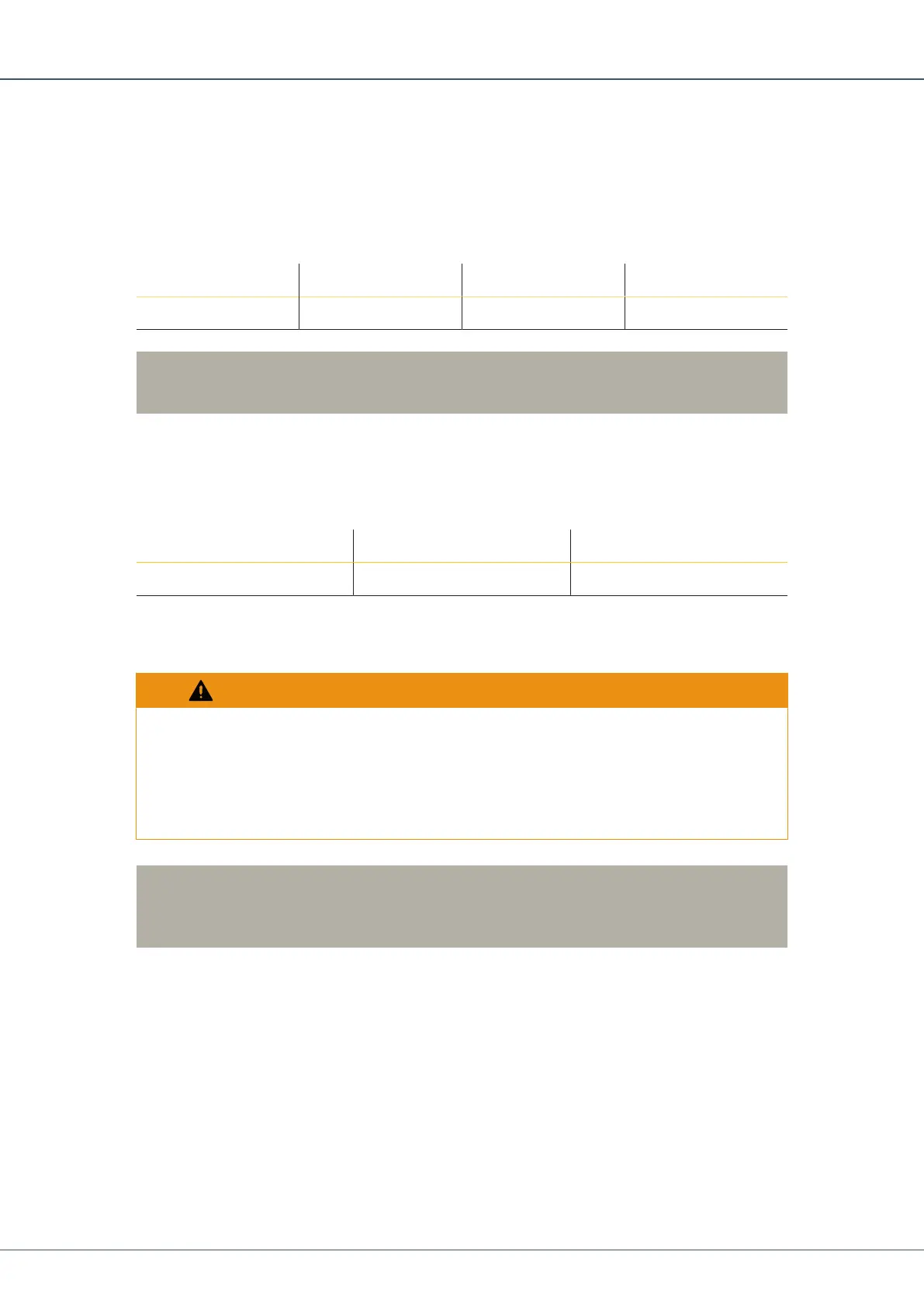

Grease Tube 0.4 kg Can 18 kg

COP Grease 3115 3422 00 3115 3423 00

11.2 Fill Air Lubricant Oil

WARNING

Serious injury

Risk of serious injury to the eyes and skin.

u Never work on the lubrication system when it is pressurised. Lubrication air and oil may

spray out.

!

NOTE: Certain moving parts on the Rock Drill are lubricated with compressed air con-

taining oil. Is important that these parts receive good lubrication. Use the recom-

mended lubrication air pressure and lubricant.

1.

Check the level in the lubrication tank on every shift. Exercise cleanliness and fill with

the right grade oil. See chapter: Lubricating.

2.

If the lubrication system is drained of oil, bleeding must take place after filling. See the

appropriate Rig manuals for instructions.

Loading...

Loading...