Maintenance 6. Joint #2

100 L

S20-B Rev.4

6.1 Replacing Joint #2 Motor

Maintenance

AC Servo Motor (520 W) 1 2197985

Tools

Hexagonal

width across flats: 2.5 mm

Cross-point screwdriver (#2)

A brake is mounted on the motor of Joints #3 and #4 to prevent the shaft from moving down

and rotating due to the weight of the end effector while the power to the Controller is OFF

or while the motor is in OFF status (MOTOR OFF).

Move the shaft down to its lower limit before the replacement procedure following the

removal steps.

Motor

Push down the shaft to its lower limit while pre

ssing the brake release switch.

Be sure to keep enough space and prevent

the end effector hitting any

peripheral

equipment.

The brake release switch is applied to both Joints #3 and Joint #4.

When the brake release switch is pressed, the respective brakes of the Joint #3 and Joint

#4

are released simultaneously.

shaft falling and rotating while the brake release switch is

because the shaft may be lowered by the weight of an end effector.

Arm Top Cover.

For details, refer to Maintenance: 3.1 Arm Top Cover.

and Duct Plate.

For details, refer to Maintenance: 3 Covers.

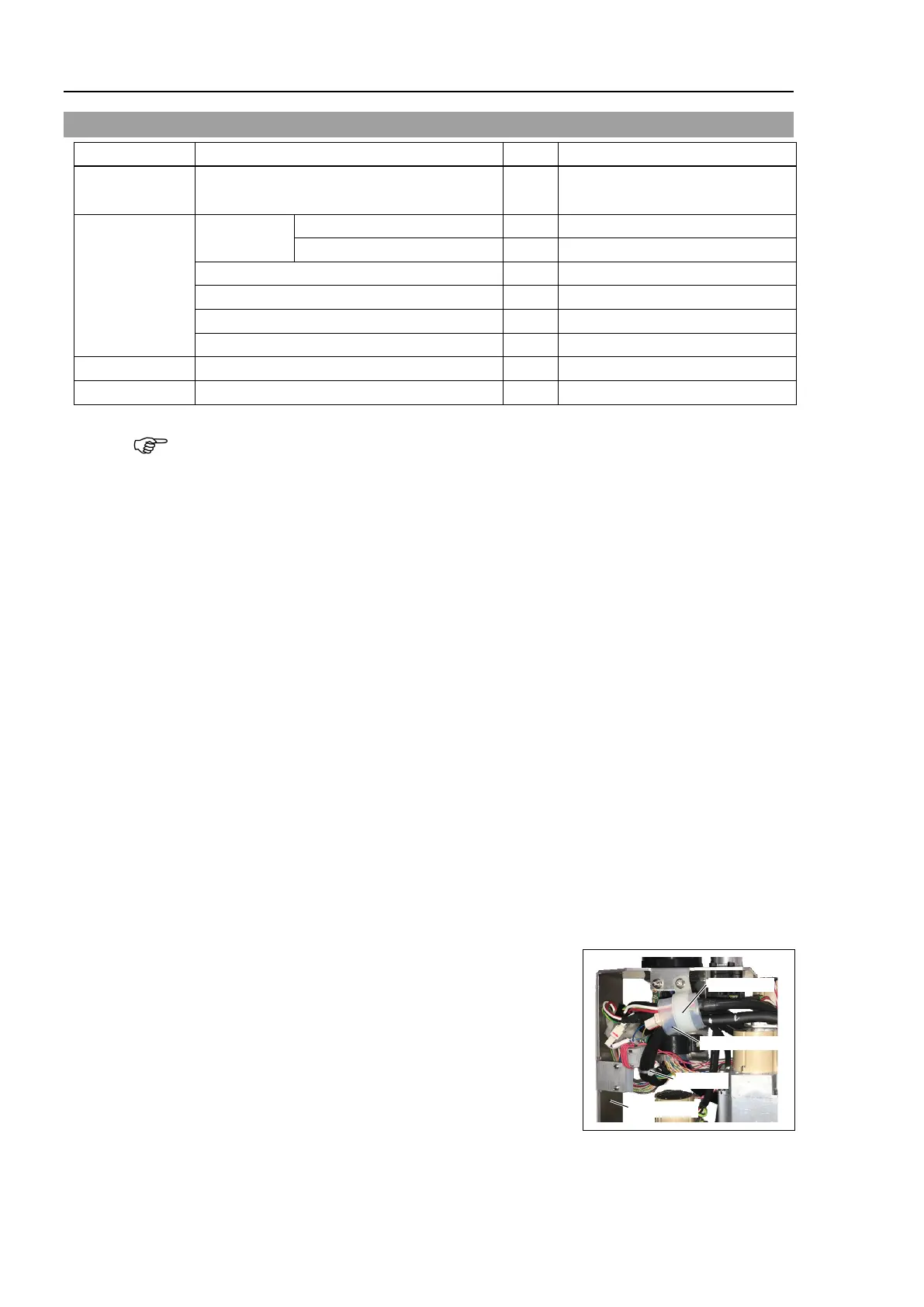

Remove the Clip Band and Sheet binding the

motor

cables.

The Clip Band and sheet will be reused

when

installing the cable unit.

Be careful not to lose them.

o not cut the wire tie (in the duct fittings outlet) that

binds the cables to the duct

plate.

Clip Band

Wire Tie

Duct Plate

Silicon Sheet

Disconnect the following connectors

.

Connectors: X221, X42 (Hold the clip to remove.)

Loading...

Loading...