Maintenance 8. Joint #4

LS20-B Rev.4 133

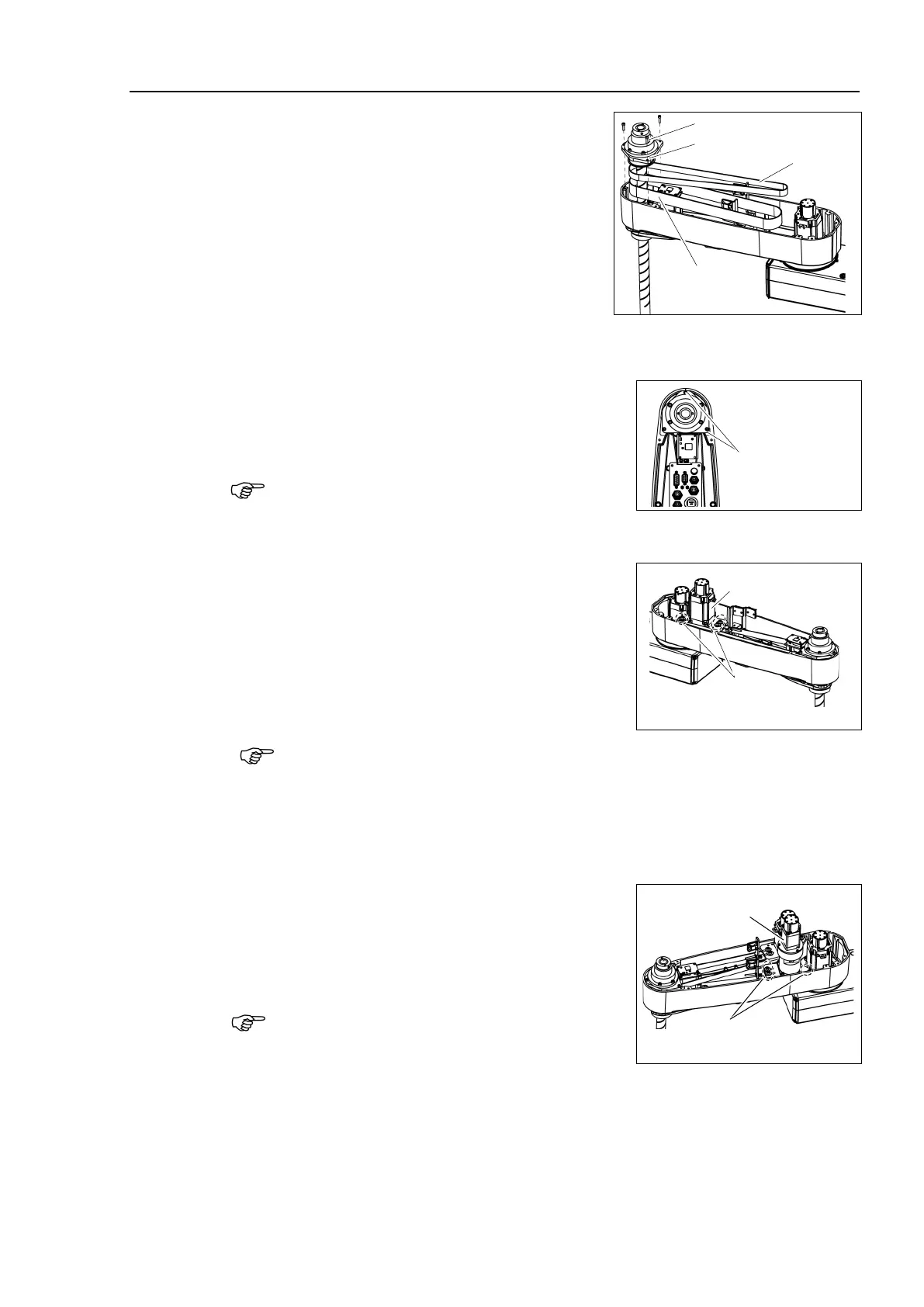

belt

)

Hold up the spline plate and set the U belt

Make sure the gear grooves of the belt are

fit

into those of the pulleys completely.

3-M4×15

Spline Plate

Z Belt

U Belt

Hold up the spline plate and set the Z belt

around the Z pulley.

Make sure the teeth of the timing belt are

engaged with those of the pulley.

Loosely secure the spline plate on the

Arm #2 and

move the shaft up and down

several times before

spline plate.

the screws so that the spline plate

hand. Fix the spline plate with

pushing the front side of the Arm

the right side face.

Faces to push

the spline plate

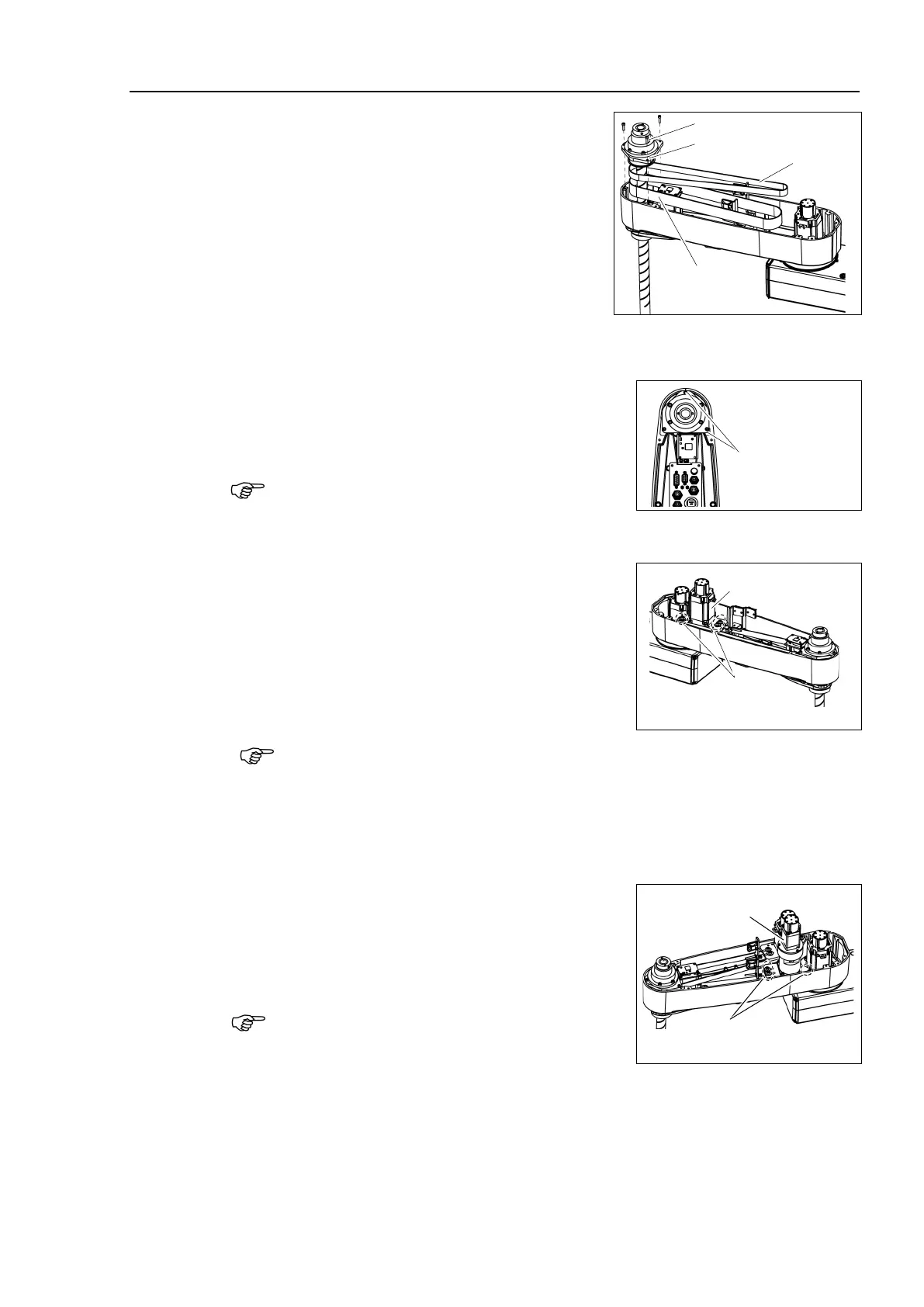

Loosely secure the Joint #3 motor unit to

the Arm

Make sure the teeth of the

timing belt are engaged

with those of the pulley.

Joint #3

Motor Unit

3-M5×20

+washer for

slotted hole

At this point, make sure that the Joint #3 motor unit can be moved by hand, and it

will not tilt when pulled.

If the unit is tilted, the belt will not have the proper tension.

pply the proper tension to the Z belt, and then secure the Joint #3 motor unit.

For details, refer to Maintenance: 7.2 Replacing the Timing Belt.

Loosely secure the Joint #4 motor unit to

the Arm

teeth of the timing belt are engaged

with those of the pulley.

ake sure that the Joint #4 motor unit can be

will not tilt when pulled.

3-M5×20

+ washer for slotted hole

Joint #4

Motor Unit

If the unit is tilted, the belt will not have the proper

tension.

Loading...

Loading...