Setup & Operation 5. Motion Range

54 L

S20-B Rev.4

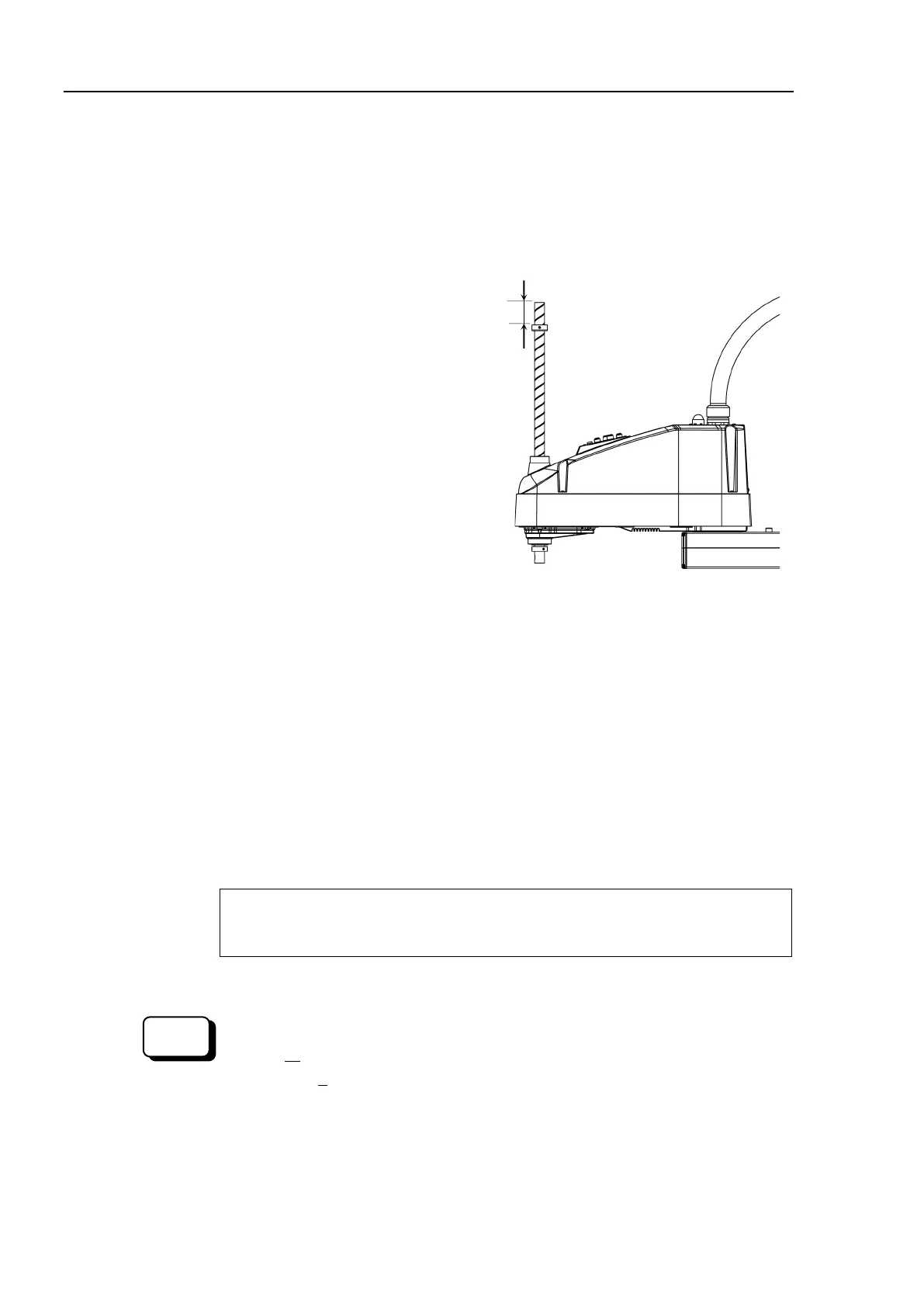

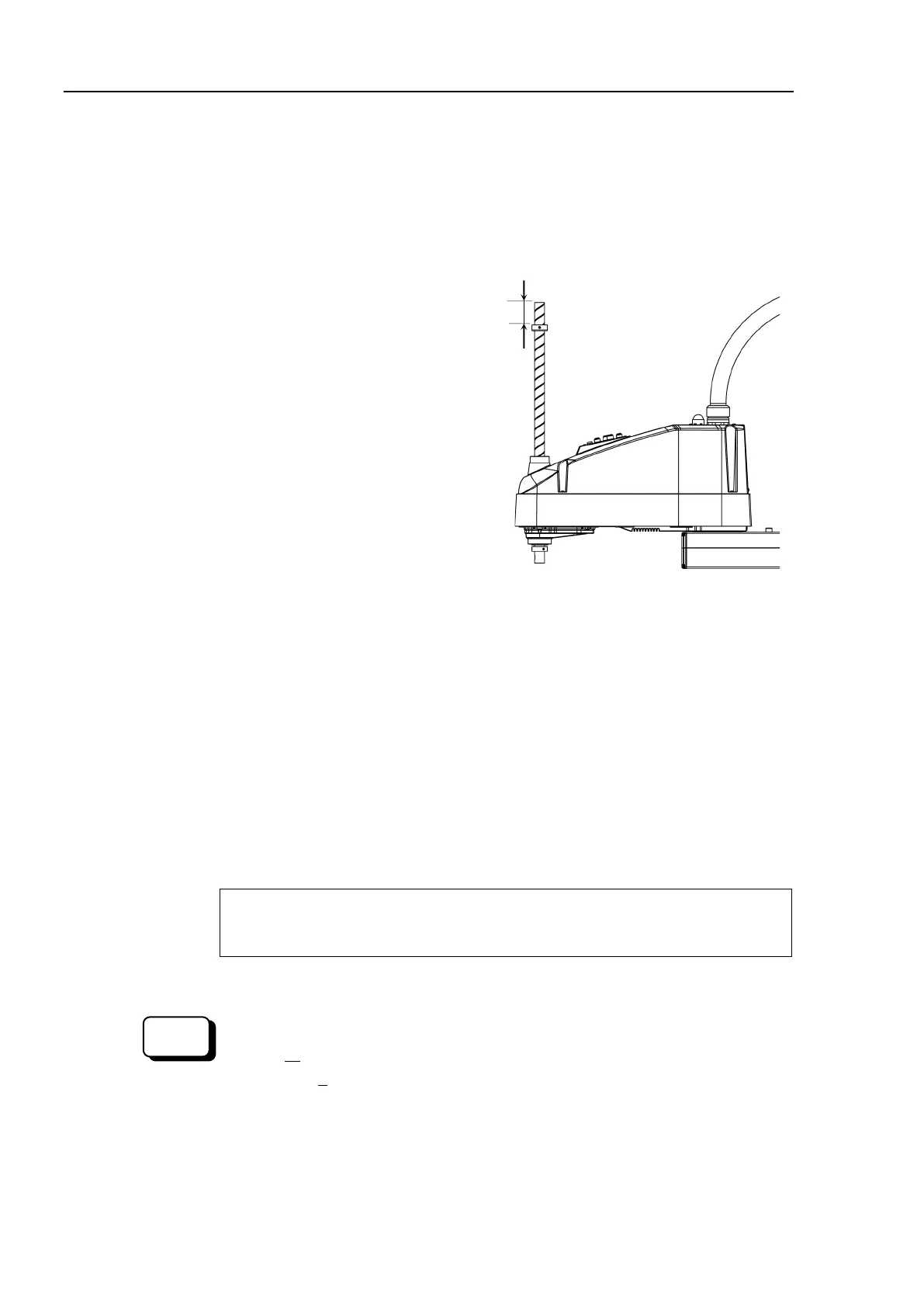

The upper end of the shaft

defines the maximum stroke. Move the lower limit

mechanical stop down by the length you want to limit the stroke.

For example, when the lower limit mechanical stop is set at

“420 mm” stroke, the

limit Z coordinate value is “−420”. To change the value to “−100”, move the

lower limit mechanical stop down

“320 mm”. Use calipers to measure the distance

adjusting the mechanical stop.

Firmly tighten the lower limit mechanical stop screw

(set screws: 2-M5×6).

Recommended tightening torque:

3.9 N·m (39.8 kgf·cm)

Controller.

Joint #3 to its lower limit while pressing the brake release switch, and

limit position. Do not lower the mechanical stop too far

may not reach a target position.

Calculate the lower limit pulse

value of the pulse range using the formula

shown below

and set the value.

T

he result of the calculation is always negative because t

he lower limit Z coordinate

value

is negative.

Lower limit of pulse (p

ulse)

= lower limit Z coordinate value (mm) / Resolution (

mm/pulse)

** For the Joint #3 resolution,

refer to the section Setup & Operation 2.4 Specifications.

Execute the following command from the [Command Window].

value in X.

>JRANGE 3,X,0 ' Sets the pulse range of Joint #3

(10)

Pulse command (Go Pulse command), move

Joint #3 to the lower limit

position of the pulse range at low speed.

If the mechanical stop range is less

than the

pulse range, Joint #3

will hit the mechanical stop and an error will occur.

When the

error occurs, either change

the pulse range to a lower setting

or extend the position of the

mechanical stop within the limit.

Loading...

Loading...