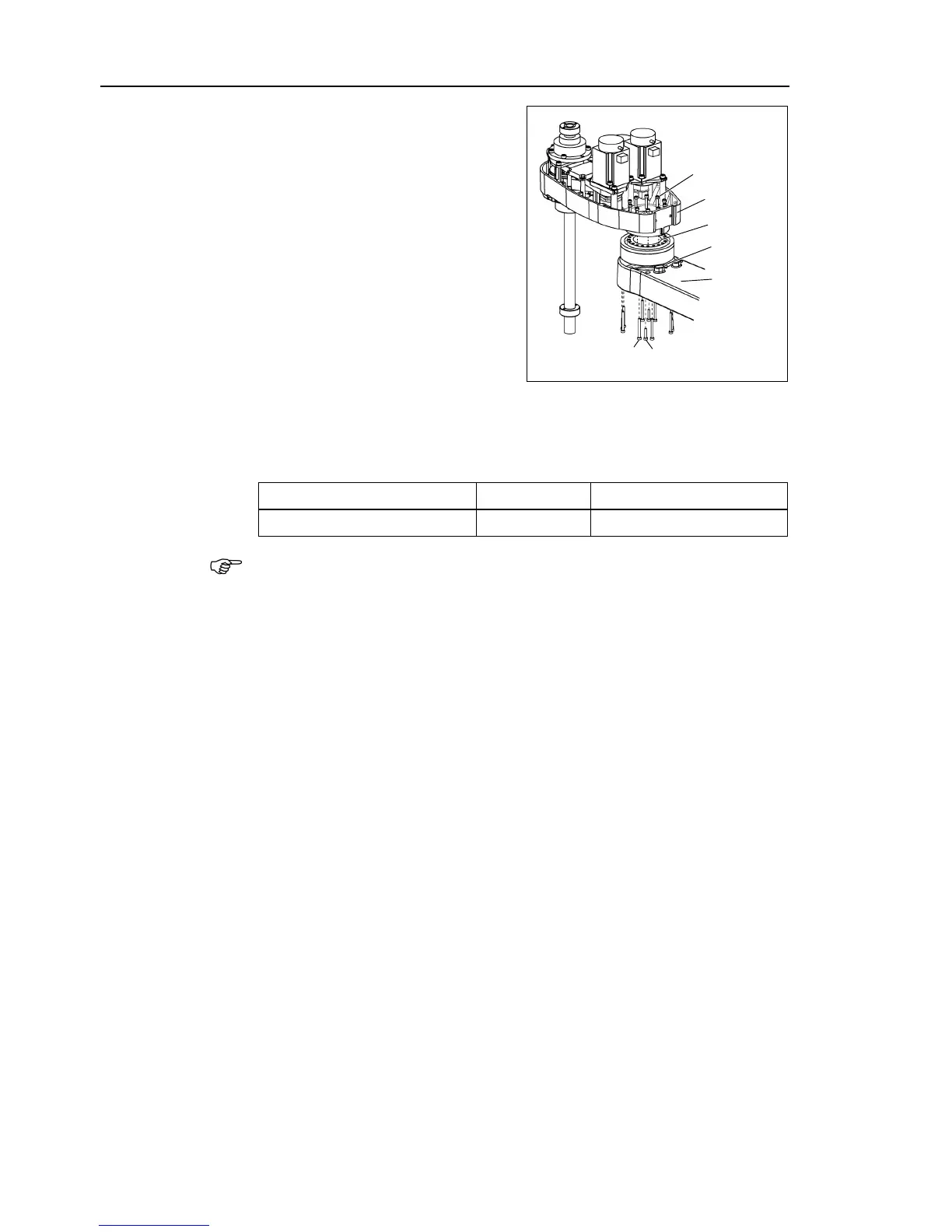

Set the O-ring removed in the removal

step (6) into the O-ring groove of the

Arm #1 and install the flexspline on the

Arm #1.

A: LS3: 10-M3×18

LS6: 16-M3×28

B: LS3: 8-M3×30+8-M3 small washer

LS6: 8-M3×32+8-M3 small washer

C: LS3: 4-M3×15+4-M3 small washer

LS6: 4-M3×12+4-M3 small washer

Loosely secure all bolts in a crisscross

pattern so that the bolts will be secured

evenly. Then, using a torque wrench,

tighten each bolt securely in a crisscross

pattern at the torque specified in the

table below.

Set the attached O-ring into the O-ring groove of the circular spline.

Secure the Arm #2 on the circular spline.

Loading...

Loading...