Maintenance 5. Arm #1

92 LS Rev.10

5.1 Replacing Joint #1 Motor

Name Quantity Note

Maintenance

AC Servo Motor (200 W) 1 R13B000102

Tools

Hexagonal wrench

Maintenance: 3.3 Connector Plate.

connector X111. (Hold the claw to remove.)

Remove the Arm #1 mounting bolt in the Joint #1 side and remove

-ring between the Joint #1 unit and the arm. Be sure to keep the O-ring.

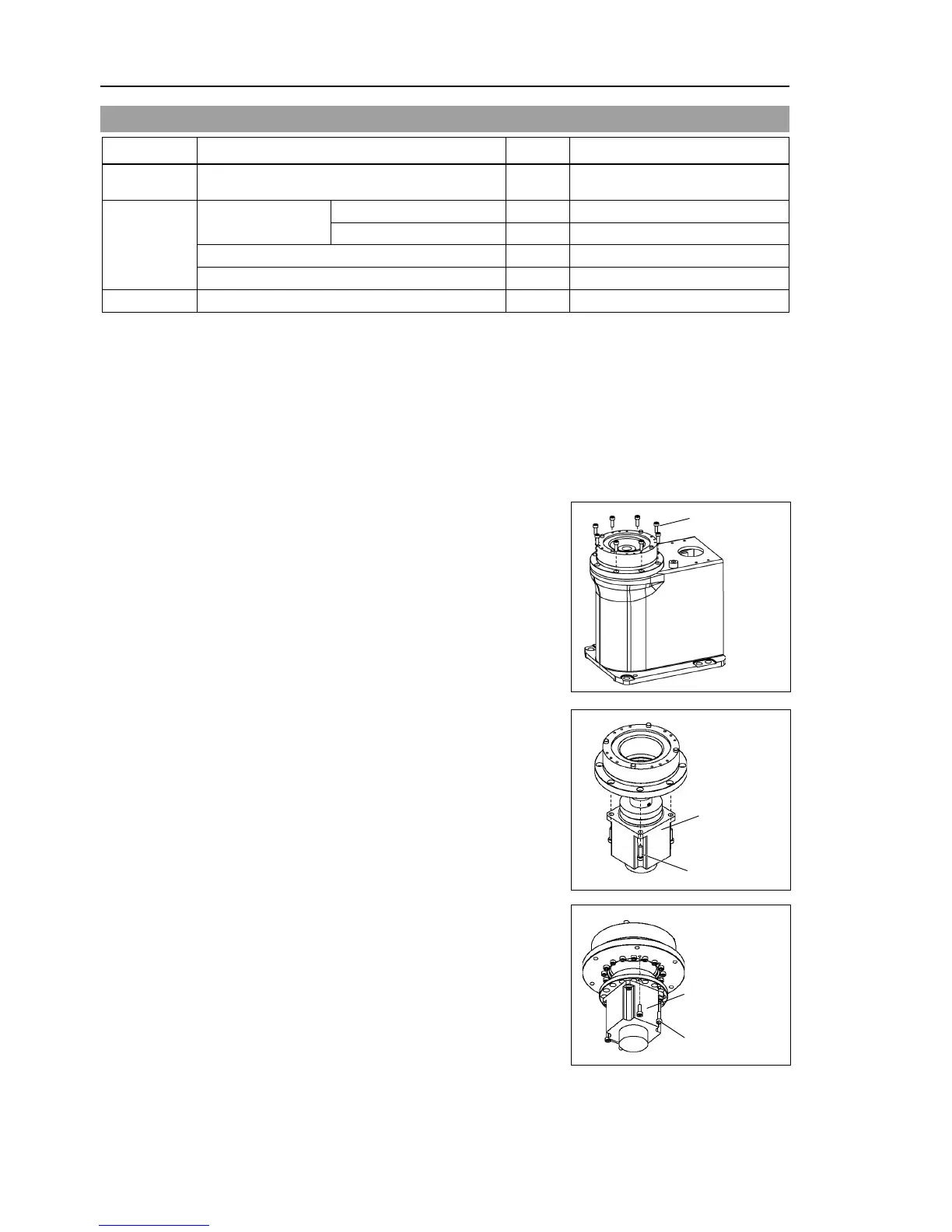

s mounting the Joint #1 flange

LS3: 8-M4×12

LS6: 6

-M5×15

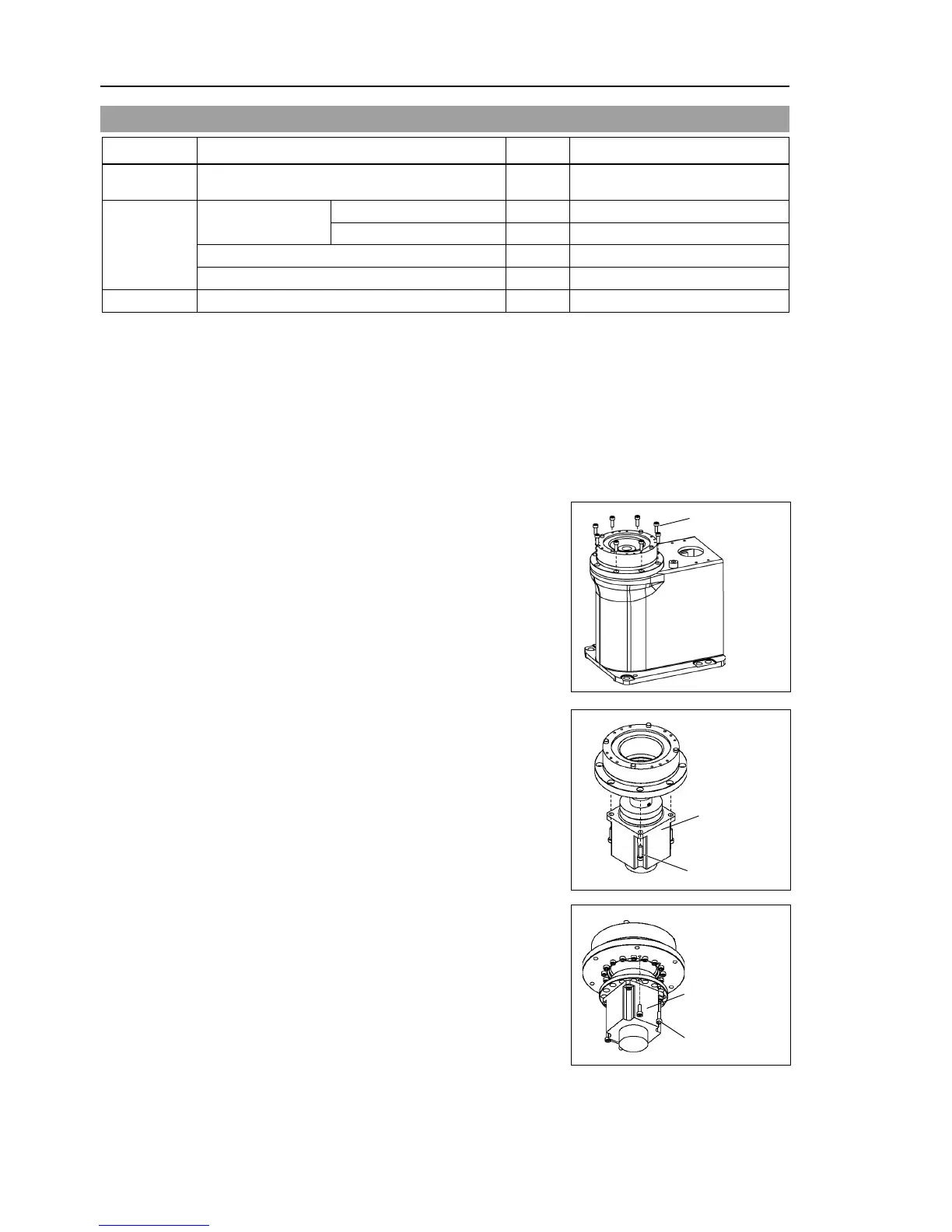

up the Joint #1 unit and remove the

connector X10 from the resolver board.

Loosen the motor mounting

motor flange and remove the

Joint #1 motor flange and remove

Loading...

Loading...