Epson Stylus C58/C59/ME 2/C79/D78/C90/C91/C92/D92/T20/T20E/T23/T26/S20/T10/T11/ME 30/T21/T24/T27/S21 Revision E

ADJUSTMENT Adjustment Items and Overview 71

Confidential

Adjustment Items

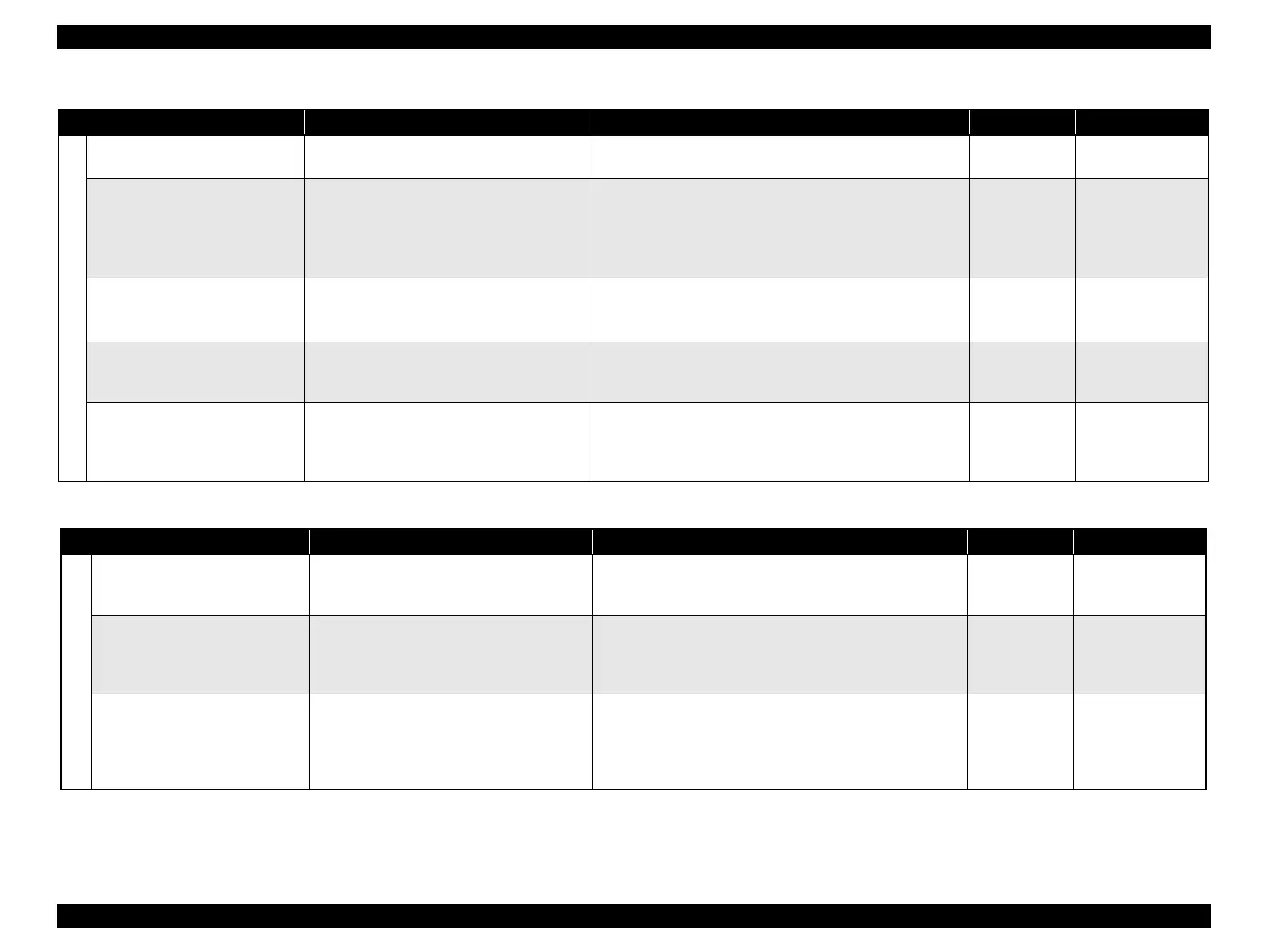

Head angular adjustment

Adjust the vertical/horizontal tilt that occur

when installing the Head, by the software.

Use the adjustment program to print the adjustment pattern and

adjust to meet the standard.

• Adjustment

Program

A4

(Plain paper)

Bi-D adjustment

This adjustment is made to correct the print

timing in the go and return paths in bi-

directional printing.

Use the adjustment program to print out the adjustment pattern,

and enter the adjustment value of the printed pattern with no

black/white streaks in the block.

Adjustment items are, each dot sizes (ECO/VSD1/VSD2/

VSD3) x Colors (Black/Color), total of 8 types.

• Adjustment

Program

A4

(Plain paper)

First dot adjustment

Correct the print timing by the software to

make the start printing position of the main

scan direction to the value you wish.

Use the adjustment program to print the adjustment pattern and

enter the adjustment value of printed position 5mm from the left

edge.

• Adjustment

Program

• Rule

A4

(Glossy paper)

PF Band adjustment

This adjustment is made to correct the

variations of Mechanism, or the paper feeding

accuracy.

Use the adjustment program to print out the adjustment pattern,

evaluate the pattern based on the criteria, and register the

appropriate adjustment value to the printer.

• Adjustment

Program

A4

(Plain paper)

CR heat protection control

Assuming production variation of the CR

Motor and the PS Board, operate this to use the

motor capacity to the maximum when the CR

Motor generates heat.

Select the replaced parts in the adjustment program, then

operate this adjustment to automatically write the appropriate

adjustment value.

• Adjustment

Program

--

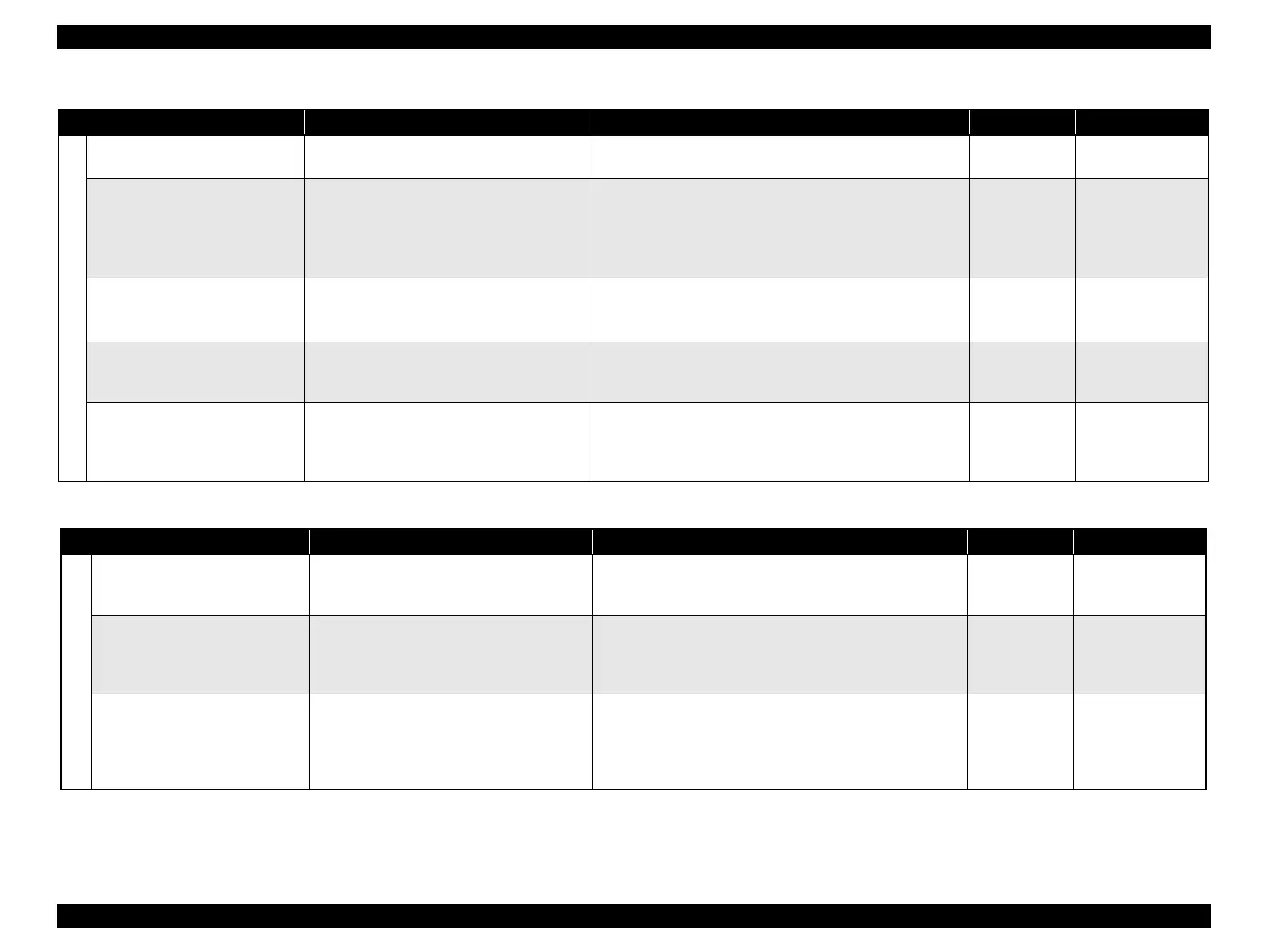

Table 5-2. Maintenance Items

Function Item Purpose Method Outline Tool Used Media

Maintenance Items

Head Cleaning

This function is used to execute Cleaning

efficiently when ink is not delivered from the

Head properly, e.g. dot missing.

Use the adjustment program to execute Cleaning, then execute

nozzle check printing.

• Adjustment

Program

A4 / Letter

(Plain Paper)

Ink charge

When replacing the Head, this function is used

to fill ink in the flow path of the Head in the

ASP to make all nozzles printable and stabilize

the ink in the Printhead.

Use the adjustment program to execute ink charge, then

execute nozzle check printing.

• Adjustment

Program A4 / Letter

(Plain Paper)

Waste ink pad counter read out/

Initialization

Initialize the Waste ink pad counter for

replaced parts after maintenance error

occurred. Also, when counter full is close, pad

exchange/counter initialization may be

executed to prevent re-fixing.

After exchanging the Waste ink pad, initialize the counter by

the adjustment program.

• Adjustment

Program

--

Table 5-1. Adjustment Items

Function Item Purpose Method Outline Tool Used Media

Loading...

Loading...