© ESAB AB 2010

-32-

bp12a2

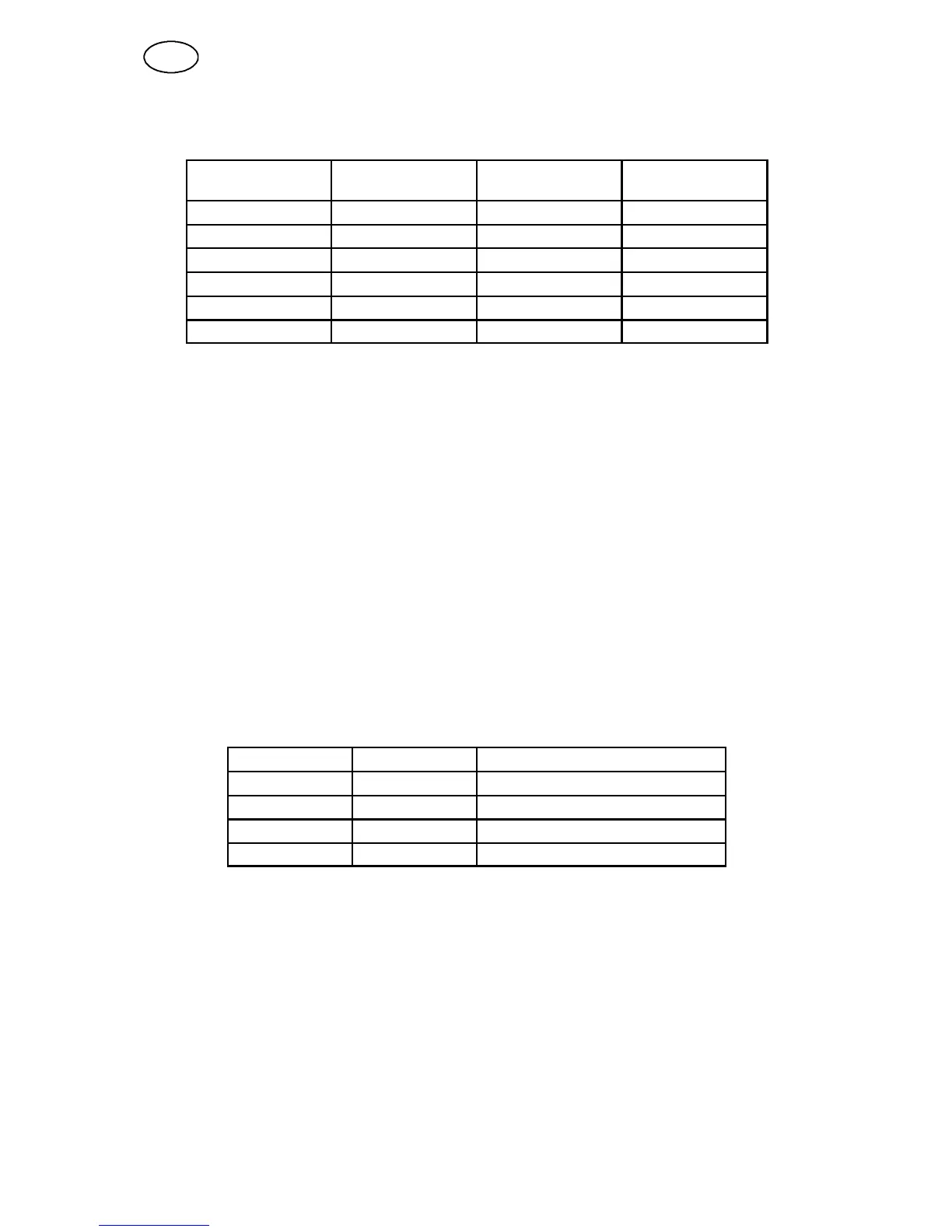

The table used to calculate the initial current, pilot current and upslope values are

stored in the micro and contains the following information:

Cut current

(amps)

Start current

(amps)

Pilot arc current

(amps)

Upslope time

(msec)

30 20 15 200

50 25 20 250

100 50 25 500

200 100 30 800

300 150 35 900

360 180 40 950

If values other than the table values are used for the cut current, the corresponding

values are calculated assuming a linear slope for all the required parameters.

2. Remote mode -

a. Partial CNC operation - ( CNC cable pin “V” open, open for internal control)

In this mode of operation the panel/remote switch needs to be in the remote

position. The CNC should be providing the cut current reference and

start/stop signal to the power source. Based on the cut reference the micro

in the power source will compute the initial current, pilot current and upslope

time.

b. Remote with Full CNC Mode - (CNC cable pin “V” closed, closed for

external control) Panel/remote switch on the power source is set to remote .

The CNC should activate the input labeled “full CNC control” on pin “ V” of the

interconnect cable. In this mode all parameters are controlled by the CNC,

including start current, pilot current and sloping times. Th e control of the pilot

current can be done either by logic inputs or by an analog input. If the analog

input is less than 0.5 volts, the power source will use the logic inputs PA0

and PA1 to provide the requested pilot arc current, based on the following

combination:

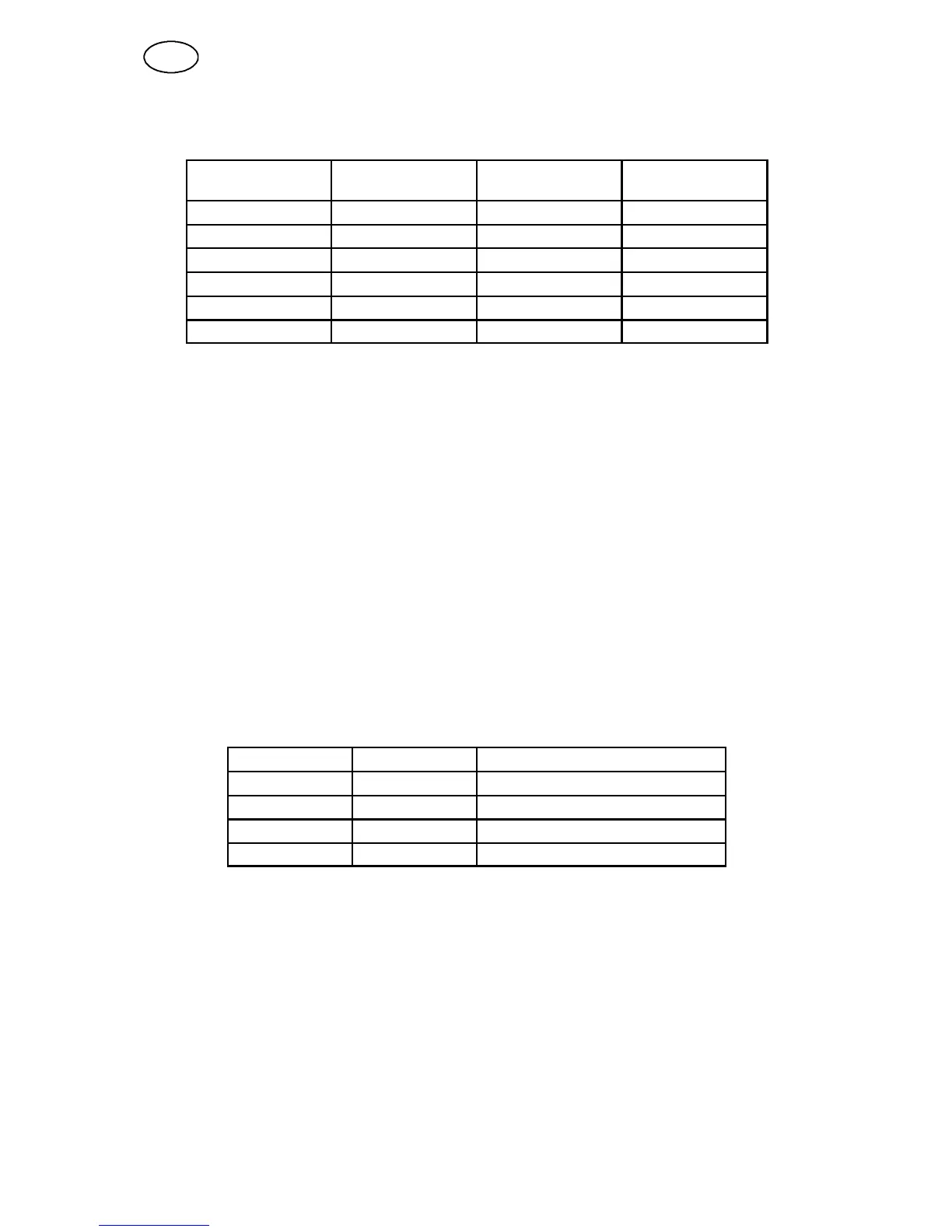

PAO PA1 Pilot current in amp

open open 10

closed open 20

open closed 30

closed closed 40

If the analog reference is used, 10 VDC will provide 45 amps or 1 V = 4.5 amps.

Marking - Can be done in both panel and remote mode and requires the mark

mode select input to be closed by the CNC. In the panel m ode the maximum

marking current (set by the panel potentiometer) is 36 amps. If SW1-1 (which is

open on the control board) is closed, the r ange becomes 0 -18 amps max. In the

remote mode the marking current is set by the main reference input and 10 VDC

will provide 36 amps or 1 V = 3.6 amps of marking current.

US

Loading...

Loading...