© ESAB AB 2010

-36-

bp12a3

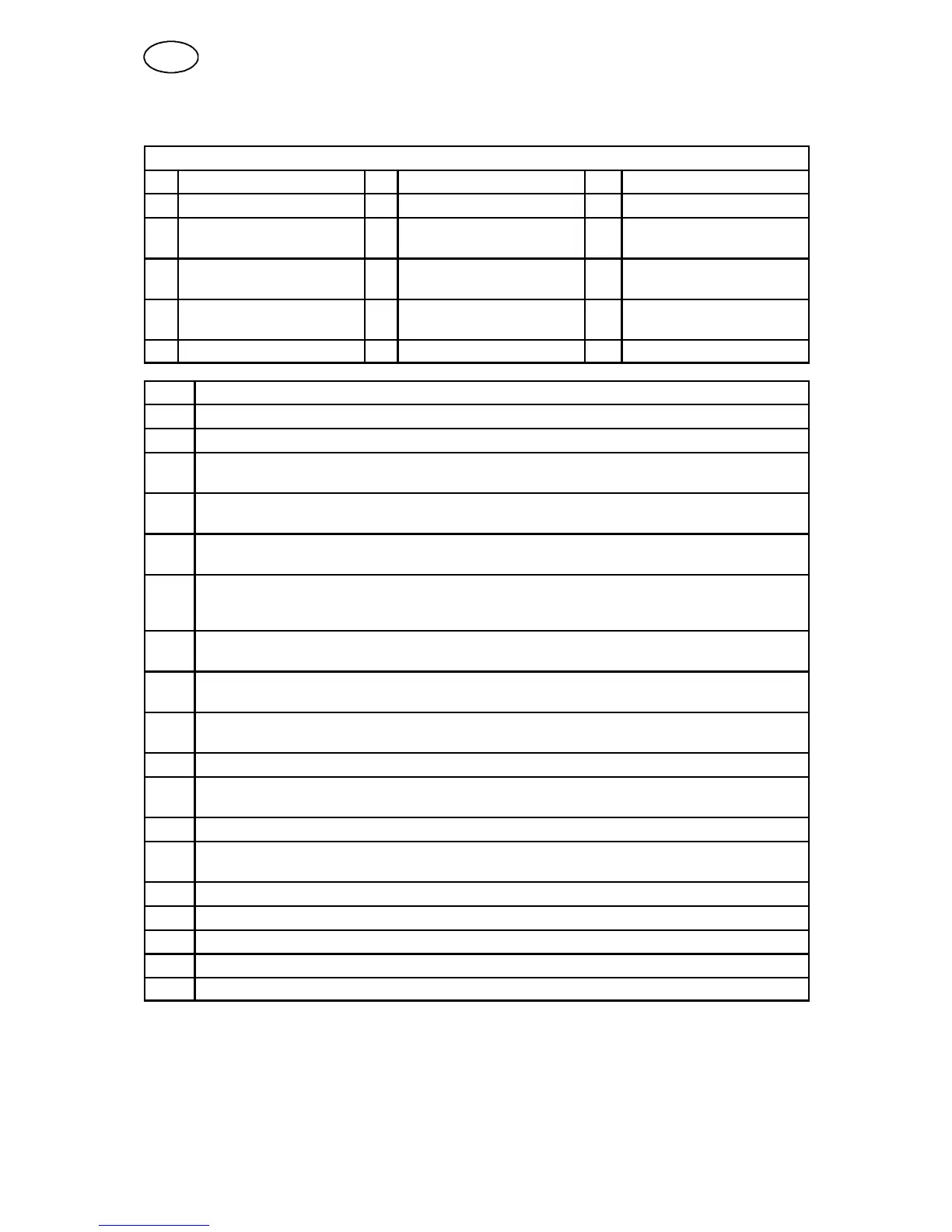

10.2 Help code list

Help codes

01 LINE VOLT, IDLE 08 TORCH ERROR 15 BUS CHARGER FAILURE

02 LINE VOLT, CUTTING 09 OCV OVER 40V, IDLE 17 IGBT DRIVER ERROR

03 CONTROL BIAS 10 OCV O VER 70V,

STARTUP

18 CUT/MARK VOLTAGE

TOO LOW

04 THERMAL (SWITCH

OPEN)

12 1Ф OPERATION,

SHUTDOWN

19 SLAVE P/S NOT

DETECTED

05 START ON POWER UP 13 OCV FAILURE 20 SHORTED IGBT, BUS

CHARGED

06 FAIL TO FIRE 14 AMBIENT TEMP 113 SLAVE P/S ERROR

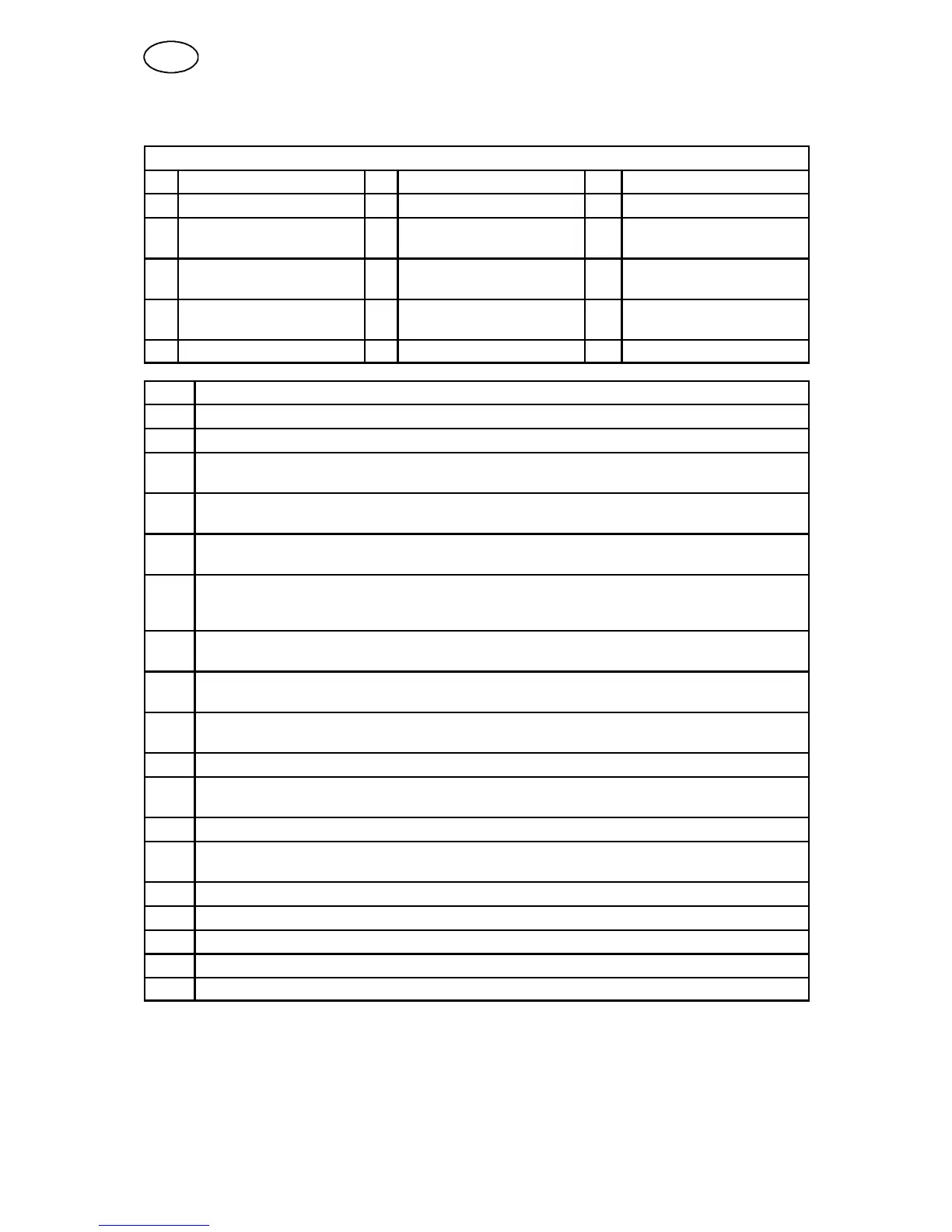

Code Error number displays and their meaning for the EPP -360 power supply.

01 +/- 15% deviation in the idle mode is exceeded.

02 Line voltage during cut drops by more than 20 %.

03 Problem with the bias supplies on the control board. The +15 and -15 volt supplies are not

balanced, board should be replaced.

04 Thermal switch has opened. Unit is disabled until overheated component cools down. Look

for fans not working or restrictions on input or output louvers

05 The start switch from the CNC was already on when the power source was powered up. Unit

will not be functional until start signal is removed and then reapplied.

06 Ignition did not take place during the 10 seconds allowed for arc ignition.

Note: This should rarely occur since the CNC has a much shorter time allowed for the

ignition time and will reset the power source to idle.

08 Electrode current was present before the PWM was enabled. Most likely caused by an

electrode to nozzle short on the torch.

09 Open circuit voltage in idle mode was over 40 volts. Possible cause leaky IGBTs, faulty

PWM drive

10 Open circuit voltage is over 70 volts when unit is powered up. Possible cause leaky IGBT’s,

faulty PWM.

12 Shut down due to single phasing. Fuse blown in supply line circuit.

13 Open circuit voltage did not reach 300 volts in the allowed time. Check PWM circuit & E-Stop

on J1.

14 Ambient temperature exceeded 55 C in control enclosure.

15 Bus voltage did not reach 100 volts during the allowed time. Bus charge relay or surge

limiting resistors defective

17 IGBT driver board error.

18 Cutting voltage fell below 70 volts during cutting or below 40 volts during marking.

19 Master is requested to engage slave power supply but slave is not present.

20 Open circuit voltage detected before PWM was engaged.

113 Error detected in slave power supply.

US

Loading...

Loading...