4

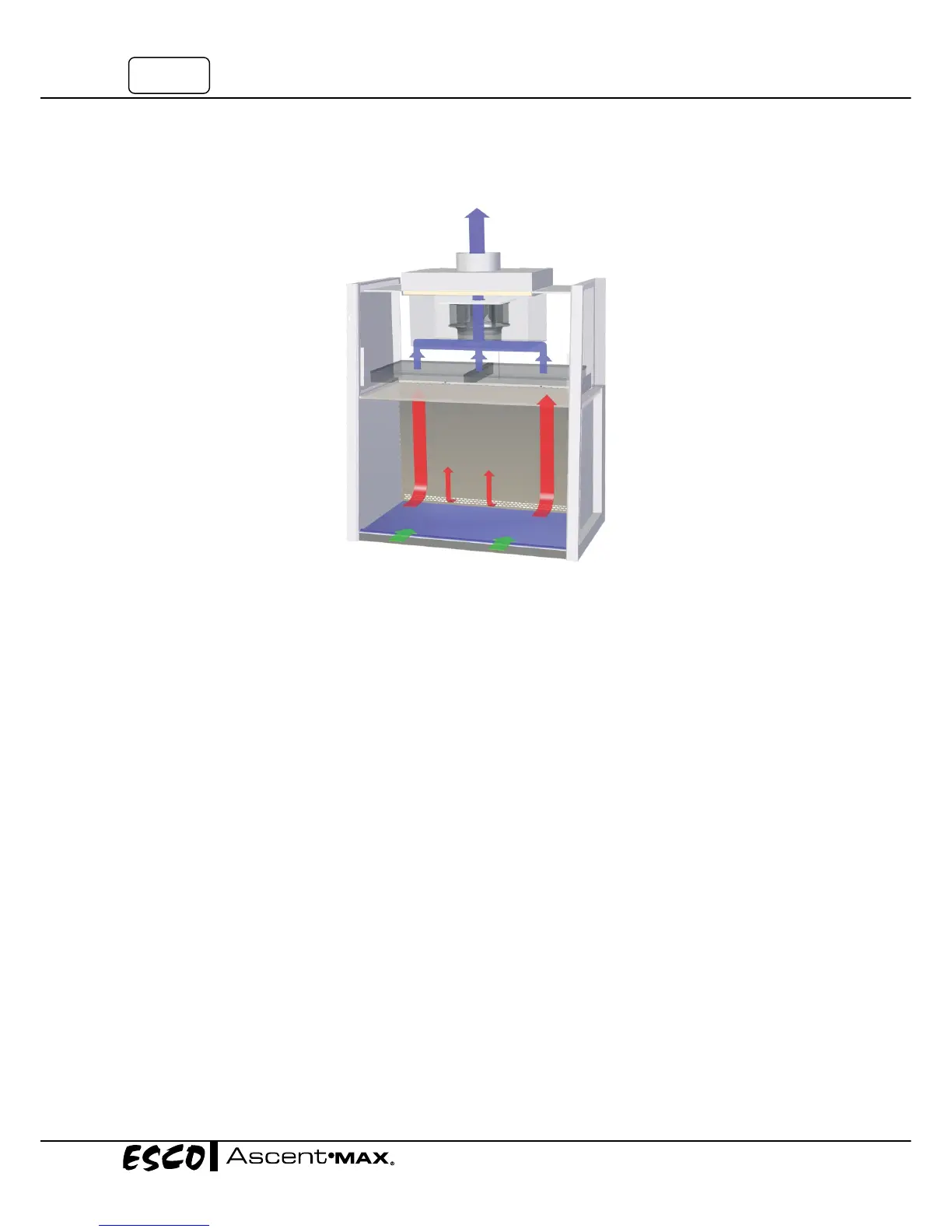

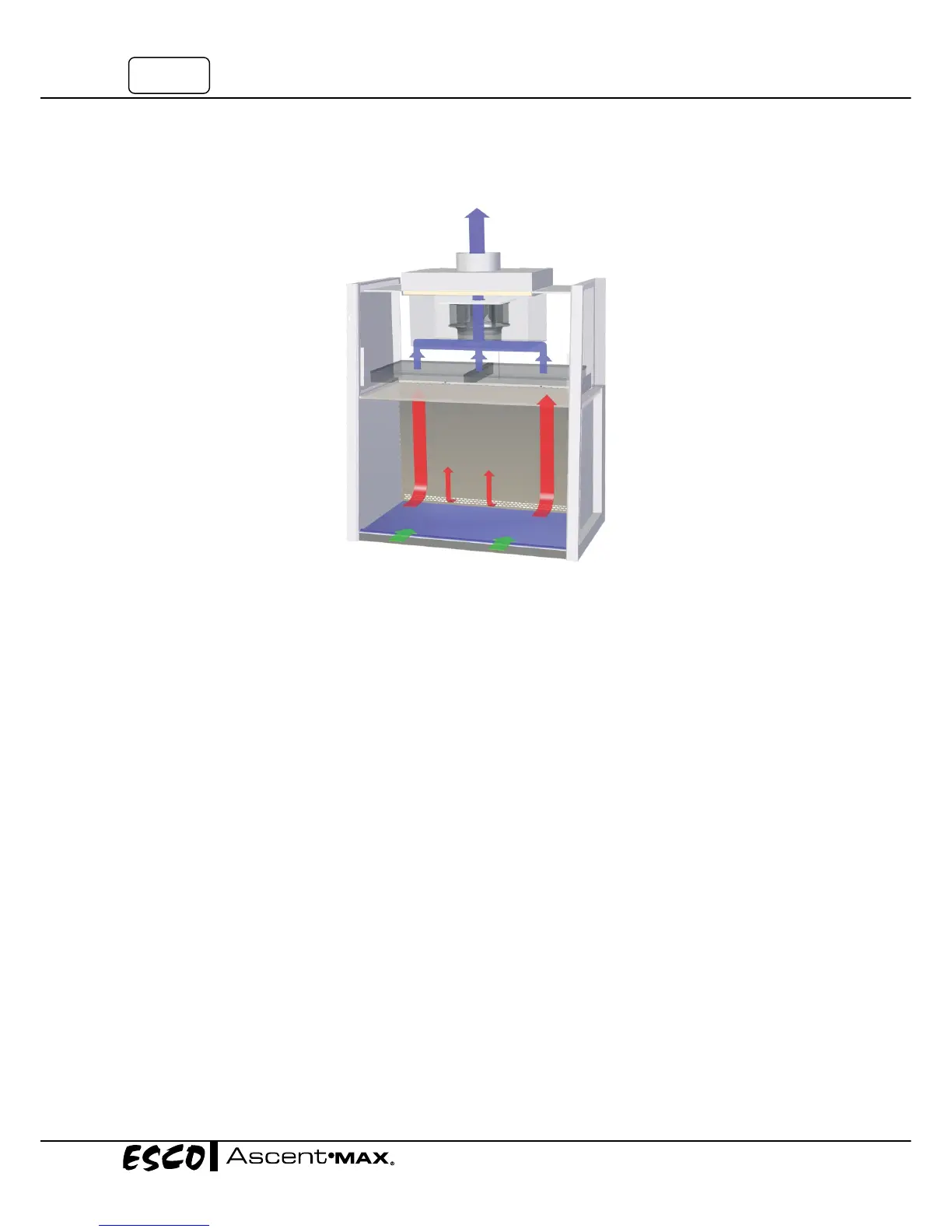

1.4AirflowPattern

1. Aninflowaircurtainfromtheambientenvironmentintothecabinetwithanaveragevelocityof0.5

m/sor100fpmisinducedbythecabinetblowersystem.

2. AdditionalinflowairtakenthroughtheAutoPurge™slotsatthebackoftheworkzonepreventsfume

accumulationforbetteroperator

protection.

3. Theinflowflushestheentireworkzoneofthecabinet;withinthemainchamberofthecabinet,

negativepressure(relativetotheambientenvironment)ismaintainedinordertoensurethatno

chemicalfumesorvaporsescapetheworkzone.

4. Airistakenthroughanactivatedcarbon

filtermountedintheinterior;thisremovesallfumesfrom

theexhaustairstream;exhaustairisre‐circulateddirectlybacktotheroomfromthetopofthe

cabinet.

1.5Filtracheck

FiltraCheckisatrademarkserviceprovidedbyEsco’sfumefiltrationdivision.Customerswhointendto

purchaseaductlessfumehoodbutareunsurewhetherthecabinetissuitablefortheirapplication,can

forwardalistofchemicalsthattheywillbehandlingandtheirpatternofusagetoEsco'sFiltraCheckservice

team.

APDFQuestionnaireformisavailableathttp://ductless.escoglobal.com/.Thisquestionnairecanbe

downloadedandeitherforwardedbyemailorbyfaxtoEsco.Aftercarefulanalysisoftheprovidedchemicals

listandpatternofusage,aproperadvicedocumentwillbegeneratedandprovidedtothecustomerin3days

period.

Thisdocumentwillrecommendtheappropriatelaboratoryequipment;ductedfumehoodorductlessfume

hoodorneitherbasedontheinvestigationdonebytheFiltraCheckteam.Dependingonthetypeofchemicals

used,thedocumentmayalsocontainalistofprocedures,warnings,etc.thatwillhelpinensuring

asafer

laboratoryworkingenvironment.Inthecaseofarecommendationofaductlesscabinet,appropriategrade

andtypeofactivatedcarbonalsobecomesafactorthathastobetakenintoconsideration.

Loading...

Loading...