21

DuctlessFumeHoods

Chapter5–ServiceandMaintenance

5.1ScheduledMaintenance

ProperandtimelymaintenanceiscrucialfortroublefreefunctioningofanydeviceandyourEscoductless

fumehoodisnoexceptiontothisrule.Westronglyrecommendthatyoufollowthemaintenanceschedule

suggestedhereunderinordertoobtainoptimalperformancefromyourEscoductlessfumehood.

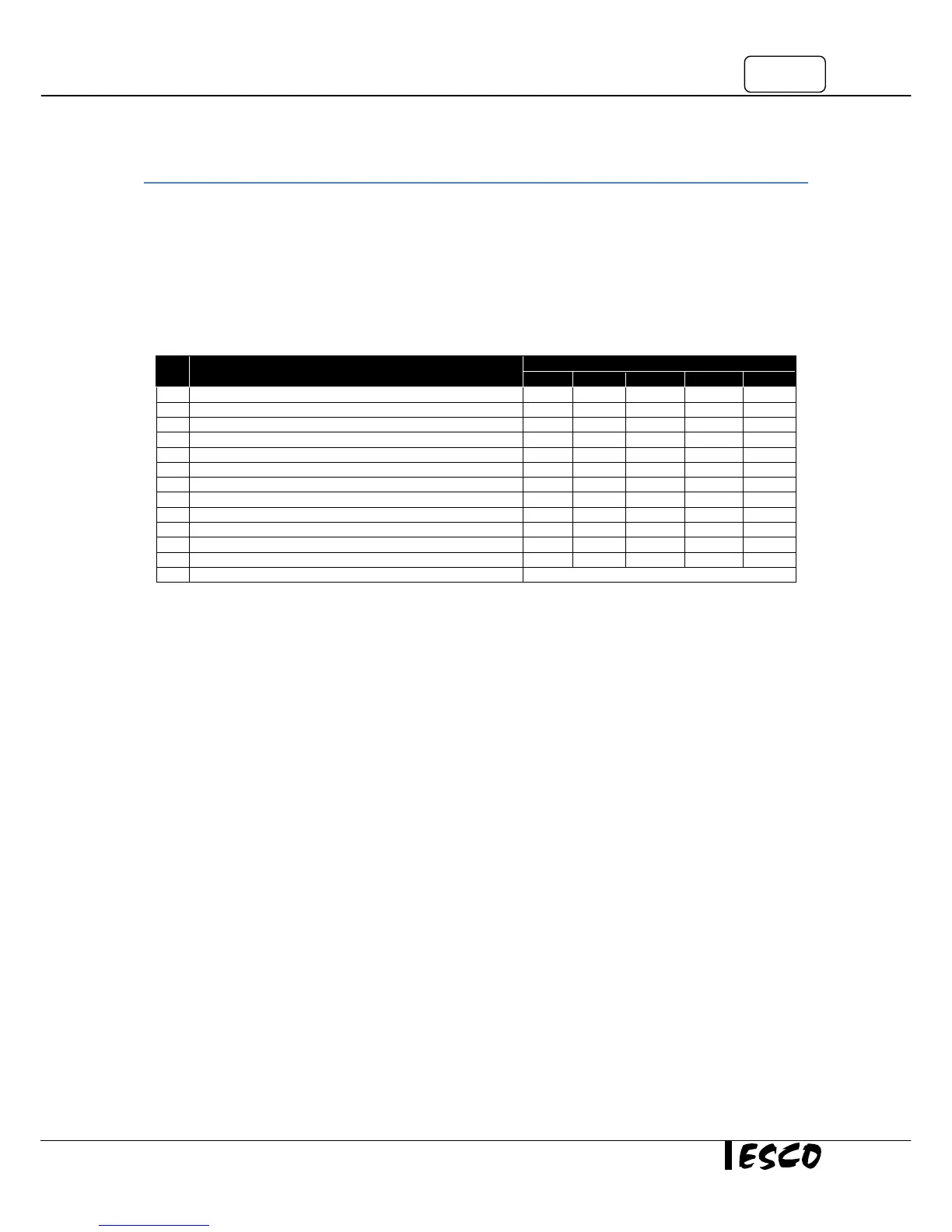

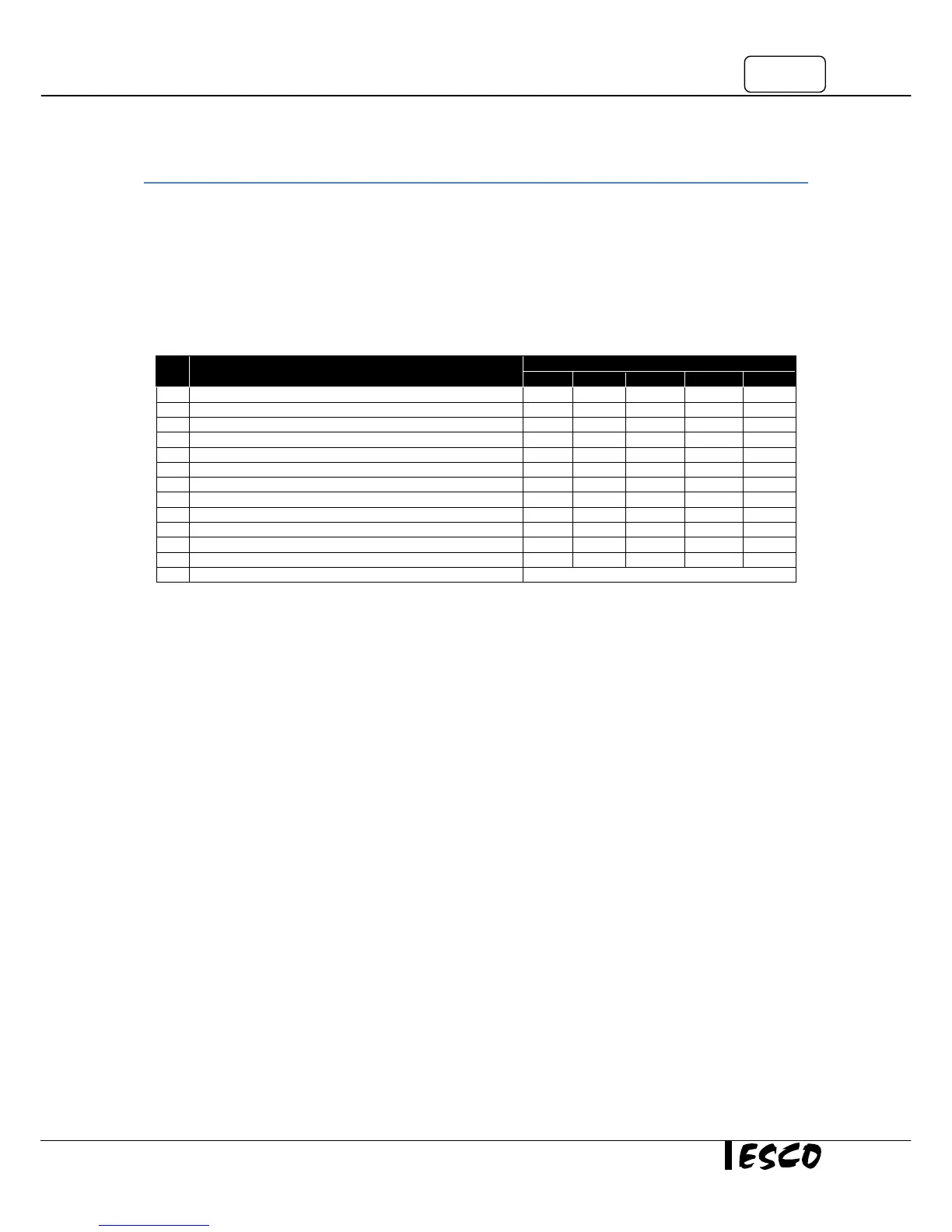

No. DescriptionofTasktoPerform

Maintenancetobecarriedoutevery

Week Month Quarter 1Year 2Years

1 Checkthealarmandmeasurethebasicairflow √

2 Cleantheinteriorworksurfaceandwallswithsoapwater √

3 Wipedownsashwithappropriateglasscleaner √

4 Cleantheexteriorsurfacesoftheductlessfumehood √

5 Measuretheductlessfumehoodfacevelocity √

6 Checkfans,motors,drivesandbearingsforproperoperation √

7 Checkfluorescenttubesforproperoperation√

8 Testtheoperationofairflowalarm√

9 Repairdefectandlubricateasnecessary√

10 CleanthestainlesssteelsurfaceusingMEK √

11 Re‐certification √

12 Changethefluorescentlamps √

13 Checkfiltersaturation (checkaccordingtoFiltracheckrecommendation)

CleaningtheHood

• Cleantheworksurfaceandwallswithsoapwater

• Cleanthesashwindowusinganappropriateglasscleaner

• Useadampclothtocleantheexteriorsurfaceofthefumehood,particularlyonthefrontandtopin

ordertoremovedustthataccumulated

there

• Usecleanwatertofinishthecleaningandwashawayanyresiduefromthesoapwaterandglass

cleaner

• Forremovingstubbornstainsorspotsonthestainlesssteelsurface,makeuseofMEK(Methyl‐Ethyl‐

Ketone).Insuchcases,makesurethatyouwashthesteelsurface

immediatelyafterwardswithclean

waterandsomeliquiddetergent.Useapolyurethaneclothorspongeforwashing.Regularlycleaning

thestainlesssteelsurfacecanhelpyouretaintheattractivefactoryfinish.

Testtheaudibleandvisualalarm

Ifpossible,covertheairflowsensor;otherwisecovertheperforationsontheback

wall–thisshoulddisrupt

theairflowofthehoodenoughtoactivatethealarm

Checkthehoodsfunctionality

• Checkthehood’smechanicalfunctionality;ex:sashwindow–lubricateifnecessary

• Checkthehood’selectricalfunctionality;ex:fluorescentlamp–replaceifnecessary

• Checkthehoodfor

anydefect,repairimmediately

Checkfiltersaturation

Checkforfiltersaturationoften.Thesaturationlevelofafilterisdirectlyaffectedbytheamountofchemical

fumegeneratedbytheexperimentconductedinsidethefumehood.Useparticlecounterbelowandabove

themain(andbackup)filterandcomparethe

resultstocheckthesaturationlevelofthecarbonfilter.

Re‐certification

Allductlessfumehoodsmustbere‐certifiedannuallybyacertifiedengineer.

Loading...

Loading...