12 www.eta.co.at

Safety devices Safety

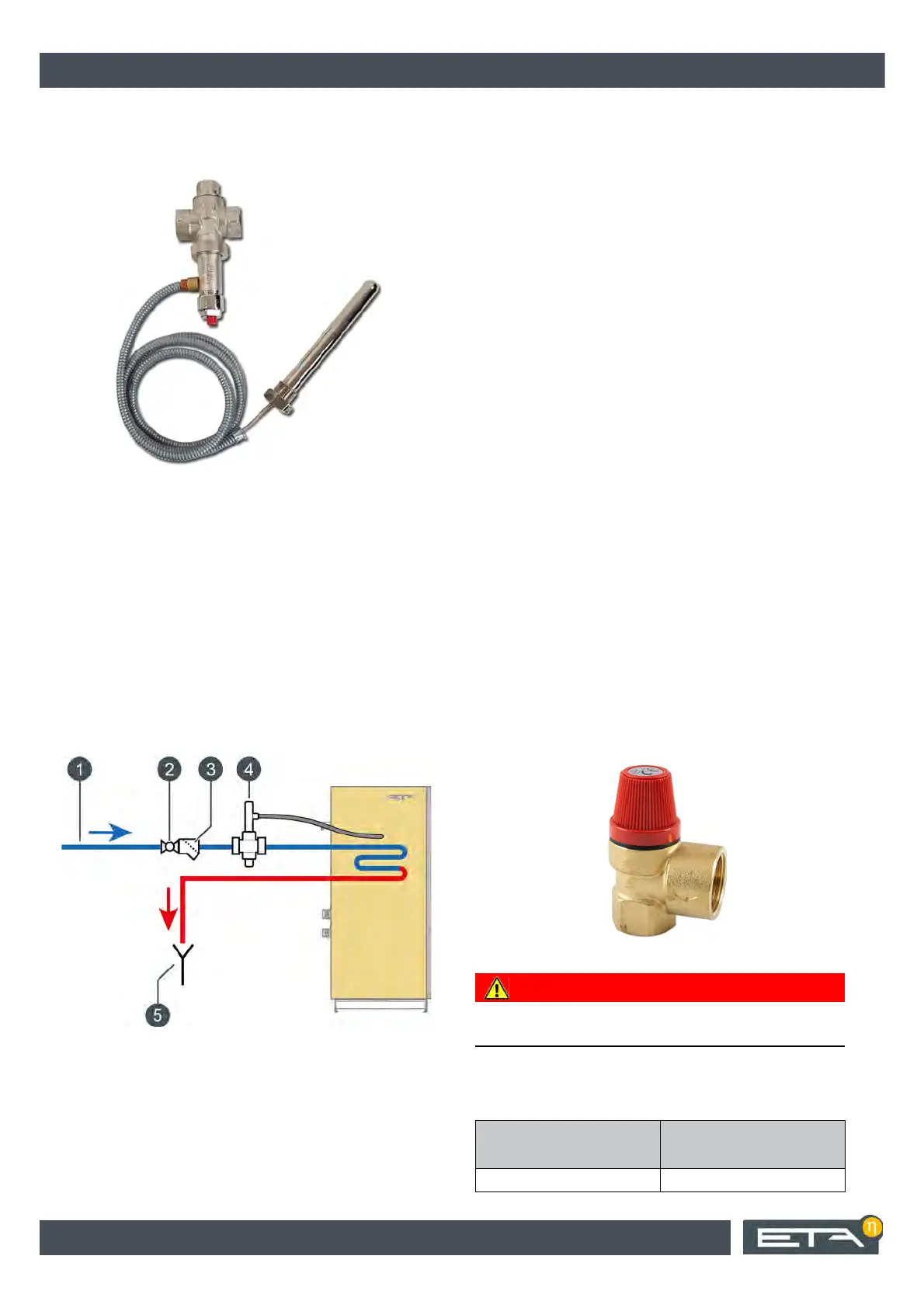

the boiler against overheating if the pump fails. The

minimum pressure in the cold water pipe must be 2 bar

and the temperature must not exceed 15 °C.

Fig. 3-2: Thermal emergency cooling valve

Only thermal emergency cooling valves that

correspond to the standard DIN EN 14597 (or

comparable standards) may be installed. They must

activate at 100 °C and have a flow rate of at least

2.0 m³/h. The clear width of the cold water supply and

outlet may not fall below the nominal diameter of the

safety heat exchanger.

The cold water supply must be connected to the upper

connector of the safety heat exchanger; the lower

connector serves as an outlet to the sewer. To prevent

the supply line from being shut off accidentally, remove

the levers from ball valves or the hand wheels from

valves and hang them there with a piece of wire.

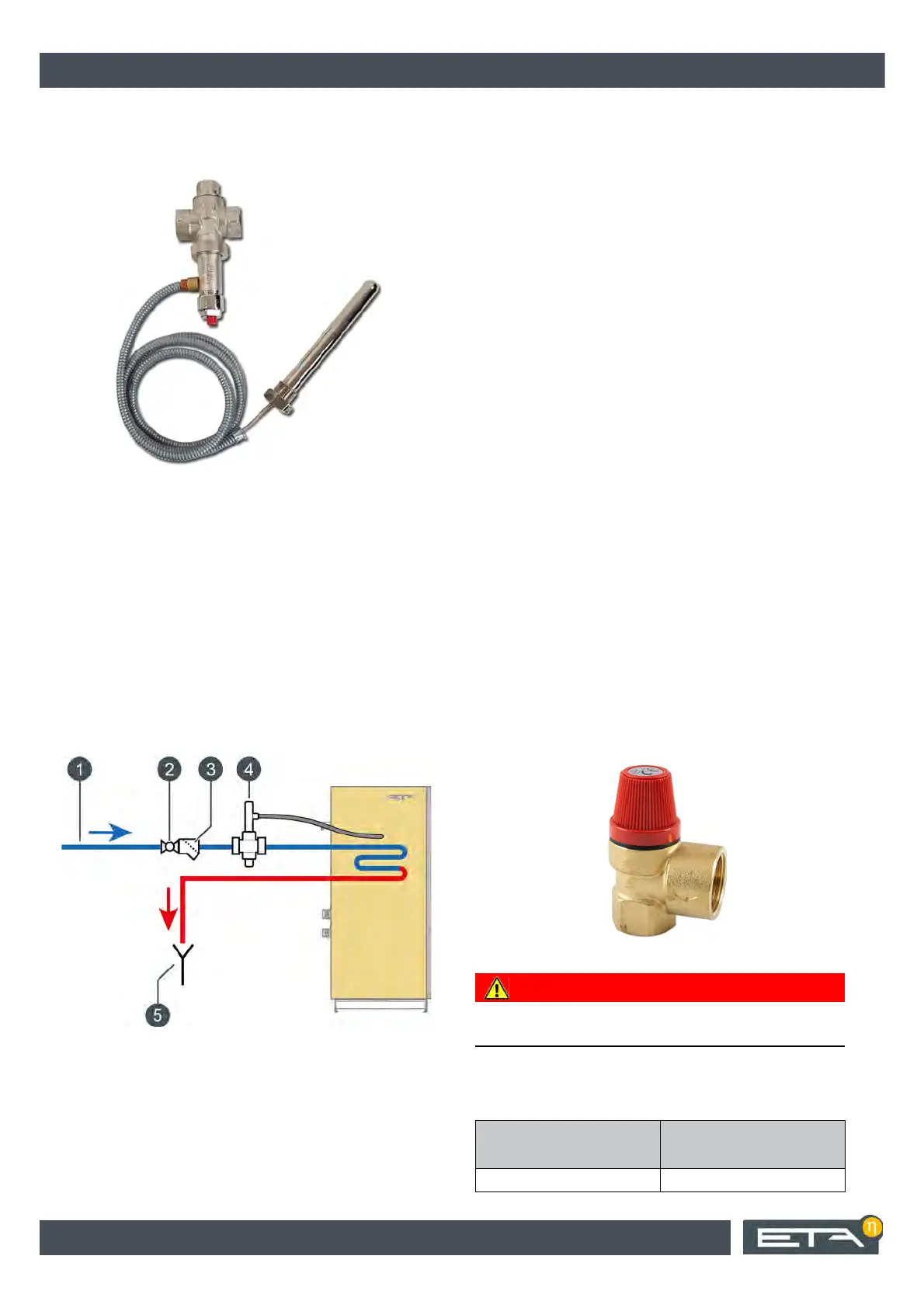

Fig. 3-3: Installation on the boiler

1 Cold water connection

2 Isolating valve; remove hand wheel

3Strainer

4 Thermal emergency cooling valve

5 Visible outlet to sewer

The outlet must have an easily visible flow path so mal-

functions can be recognised. Direct the discharged

water to the sewer via a siphon funnel or at least with

a pipe into the ground so that nobody can be scalded

if the valve is activated.

Even for cold water coming from a domestic well with

its own pump, a thermal emergency cooling valve must

be installed on the boiler. With a generously

dimensioned air vessel, enough water for cooling will

come even if there is a power failure. If the power

supply is very uncertain, a dedicated air vessel for the

thermal emergency cooling valve is required.

Safety shutdown by safety temperature limiter

For additional safety against boiler overheating, a

safety temperature limiter is built into the boiler. When

a boiler temperature of 105°C (tolerance 100 to 106°C)

is reached, it blocks the draught fan so that it can no

longer be switched on. When the boiler temperature

decreases below 70°C again, the safety temperature

limiter can be manually released for a restart of the

boiler.

Installing a safety valve against overpressure

A safety valve with 3 bar opening pressure must be

installed on the boiler. Every heat producer in a heating

system must be protected by at least one safety valve

against pressure exceeding the maximum permissible

operating pressure (see EN 12828). These valves

must be designed such as to ensure the maximum

permissible operating pressure that can arise in the

heating system or parts thereof. The safety valve must

be situated in the boiler room and be easily accessible.

Fig. 3-4: Safety valve

DANGER!

Do not install any shut-off valves, strainers or such like

between the boiler and the safety valve.

The connection size of the safety valve is determined

on the basis of the heating system's maximum heating

capacity, as shown in the table.

Valve size

a

Nominal diameter (DN)

Maximum heating ca-

pacity (kW)

15 (G ½) 50

Loading...

Loading...