275

GEARCASE

PROPELLER SERVICE

13

PROPELLER SERVICE

Inspection

Carefully examine propeller and outboard for the

following:

• Damaged blades and signs of propeller cavita-

tion (burned paint, etc.)

• Spun or overheated inner hub

• Worn or twisted splines and inadequate lubri-

cant

• Damaged or missing converging ring (if applica-

ble)

• Damage to outer hub area

• Worn, missing, or incorrect thrust washer and

spacer

• Correct size and style

• Check for bent or damaged propeller shaft and

twisted splines.

Refer to Propeller Hardware Installation on

p. 61.

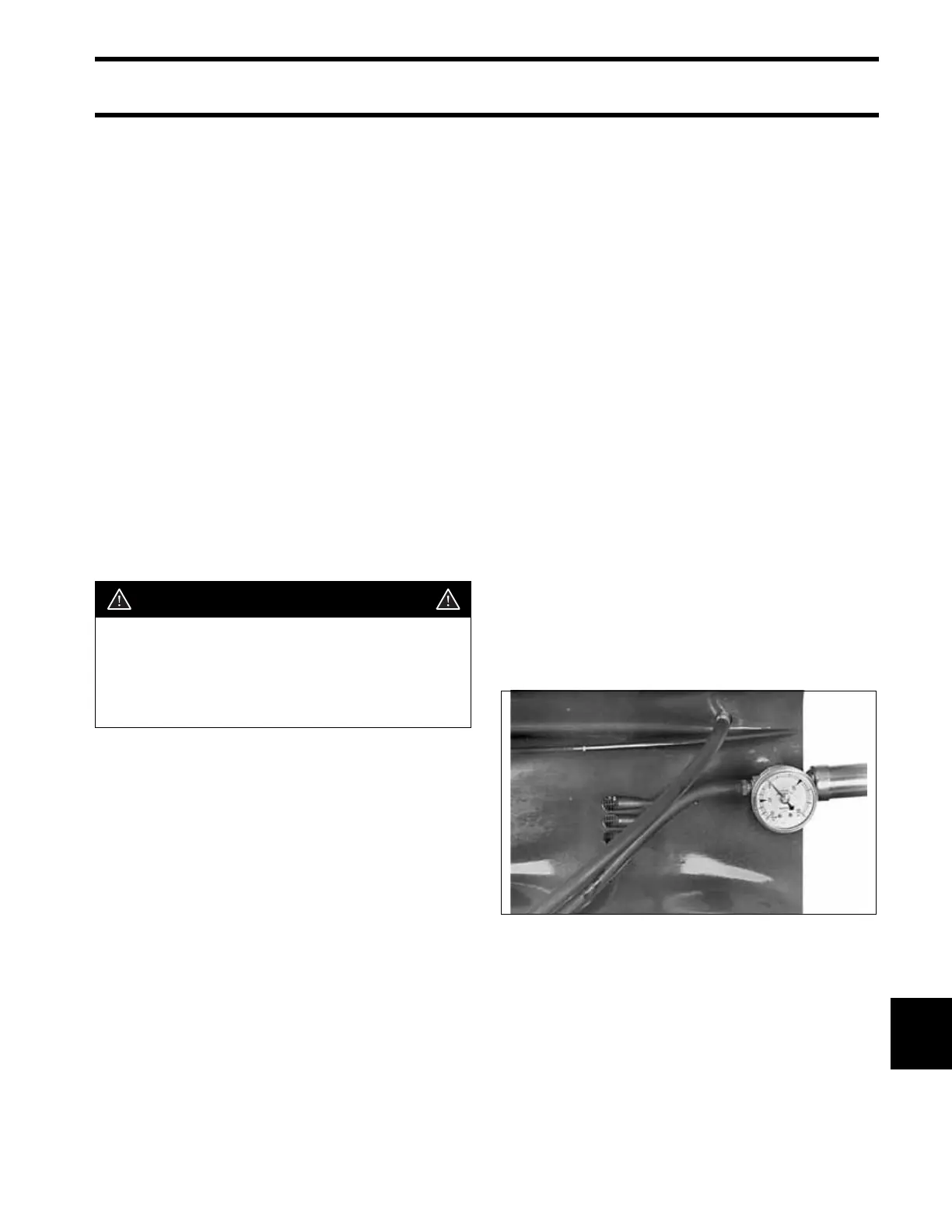

GEARCASE LEAK TEST

Drain lubricant before testing.

Install lubricant drain/fill plug and seal, thread

pressure test gauge fitting and seal in lubricant

level hole.

Pressurize 3 to 6 psi (21 to 42 kPa).

If pressure gauge indicates leakage, submerge

the gearcase in water to determine source of leak.

If the gearcase pressure gauge does not indicate

leakage, increase pressure to 16 to 18 psi (110 to

124 kPa). Check for leakage.

Make necessary repairs and repeat test.

Install vacuum test gauge. Apply 3 to 5 in. of vac-

uum (76 to 127 mm) Hg. with pump.

Check for leaks.

If leakage occurs, apply oil around suspected

seal. If leak stops or oil is drawn in, that seal is

defective.

Repeat test, gearcase must hold minimum of 15

in. vacuum (381 mm) Hg.

WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL, turn the key

switch OFF, and disconnect the battery

positive (+) cable so the outboard cannot

be started accidentally.

27022

Loading...

Loading...