277

GEARCASE

GEARCASE REMOVAL AND INSTALLATION

13

may prevent seating of the driveshaft in the crank-

shaft.

Apply Adhesive 847 to the exhaust housing seal’s

inner surface. Place the seal on the exhaust hous-

ing. Apply Triple-Guard grease to the seal’s outer

surfaces.

Slide the gearcase into place, making sure:

• Driveshaft engages the crankshaft.

• Inner exhaust housing installs correctly.

• Shift rod does not turn and is positioned prop-

erly in shift shaft connection area.

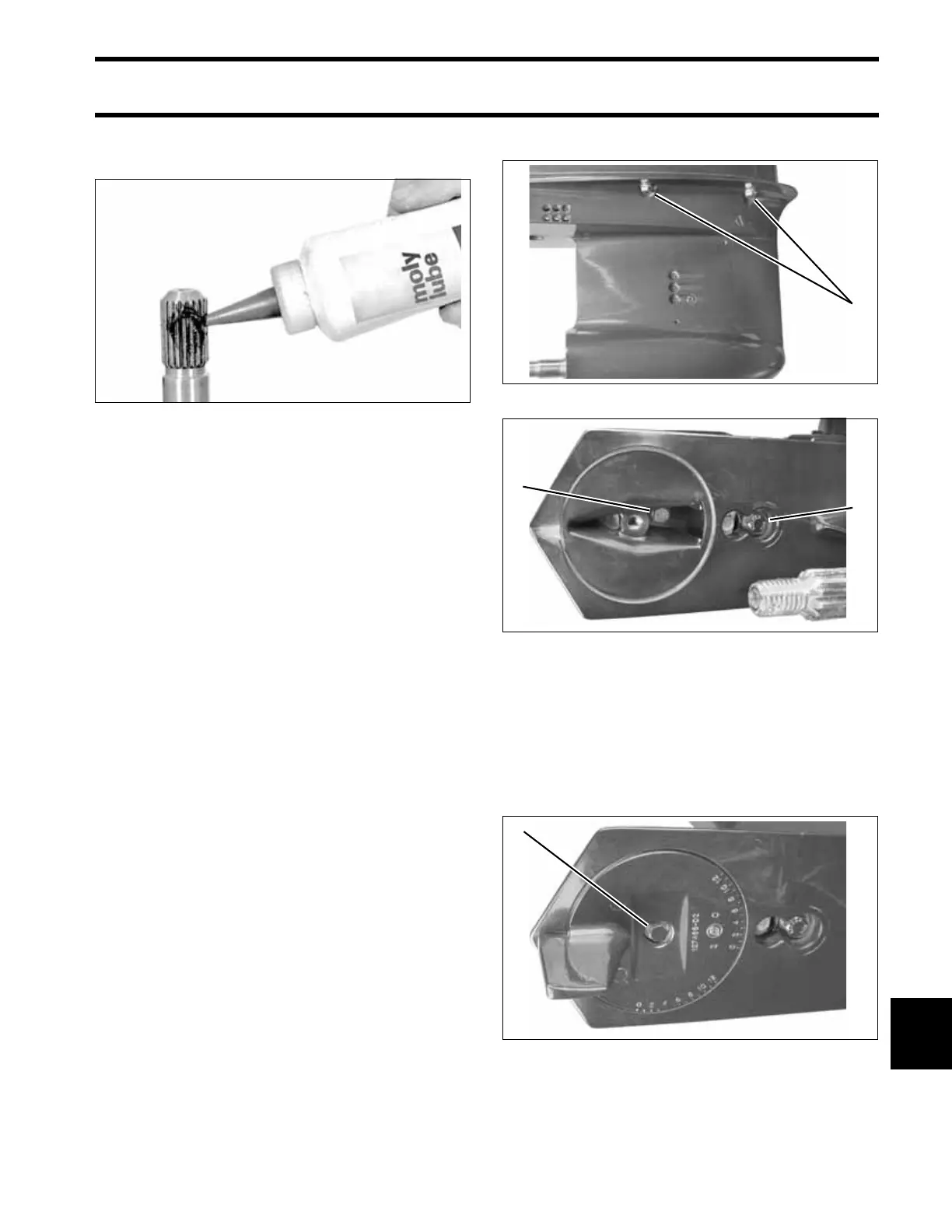

Apply Gasket Sealing Compound to threads of the

gearcase retaining screws. Tighten the screws to

a torque of:

• 3/8 in. screws – 18 to 20 ft. lbs. (24 to 27 N·m)

• 7/16 in. screw – 28 to 30 ft. lbs. (38 to 40 N·m)

• 5/16 in. screw – 10 to 12 ft. lbs. (13.5 to 16 N·m)

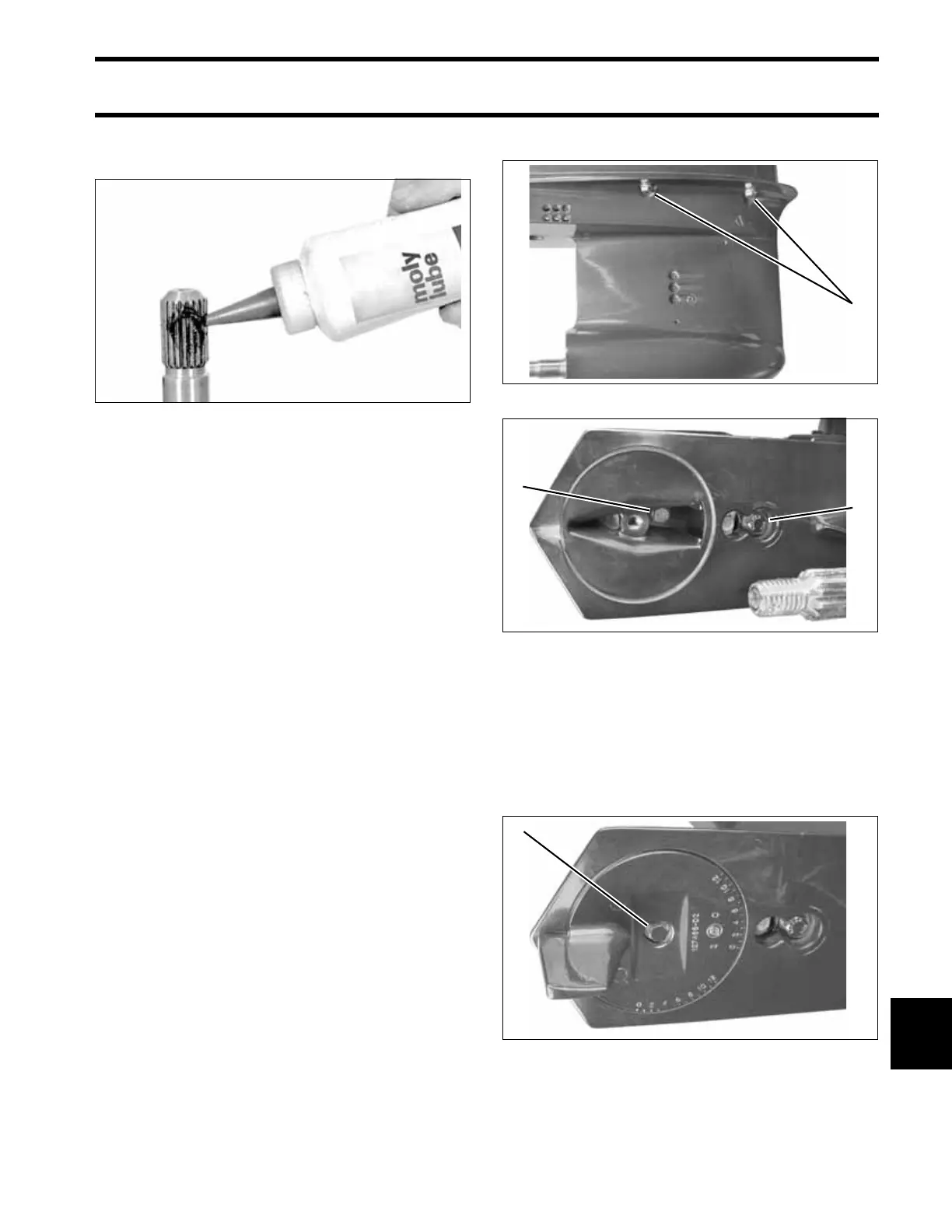

Apply Gasket Sealing Compound to threads of the

trim tab screw. Install and align the trim tab with

the index marks noted prior to disassembly.

Tighten the trim tab screw to a torque of 35 to 40

ft. lbs. (47 to 54 N·m). For adjustment, refer to

Trim Tab Adjustment on p. 63.

30385

1. 3/8 in. screws 001994

1. 7/16 in. screw

2. 5/16 in screw

001995

1. Trim tab screw 001996

1

1

2

1

Loading...

Loading...