34000 Autry Street, Livonia, MI 48150 • 800.968.5530 • Fax 734.419.0209 • www.hamiltonengineering.com • LIT91127 REV 3/09

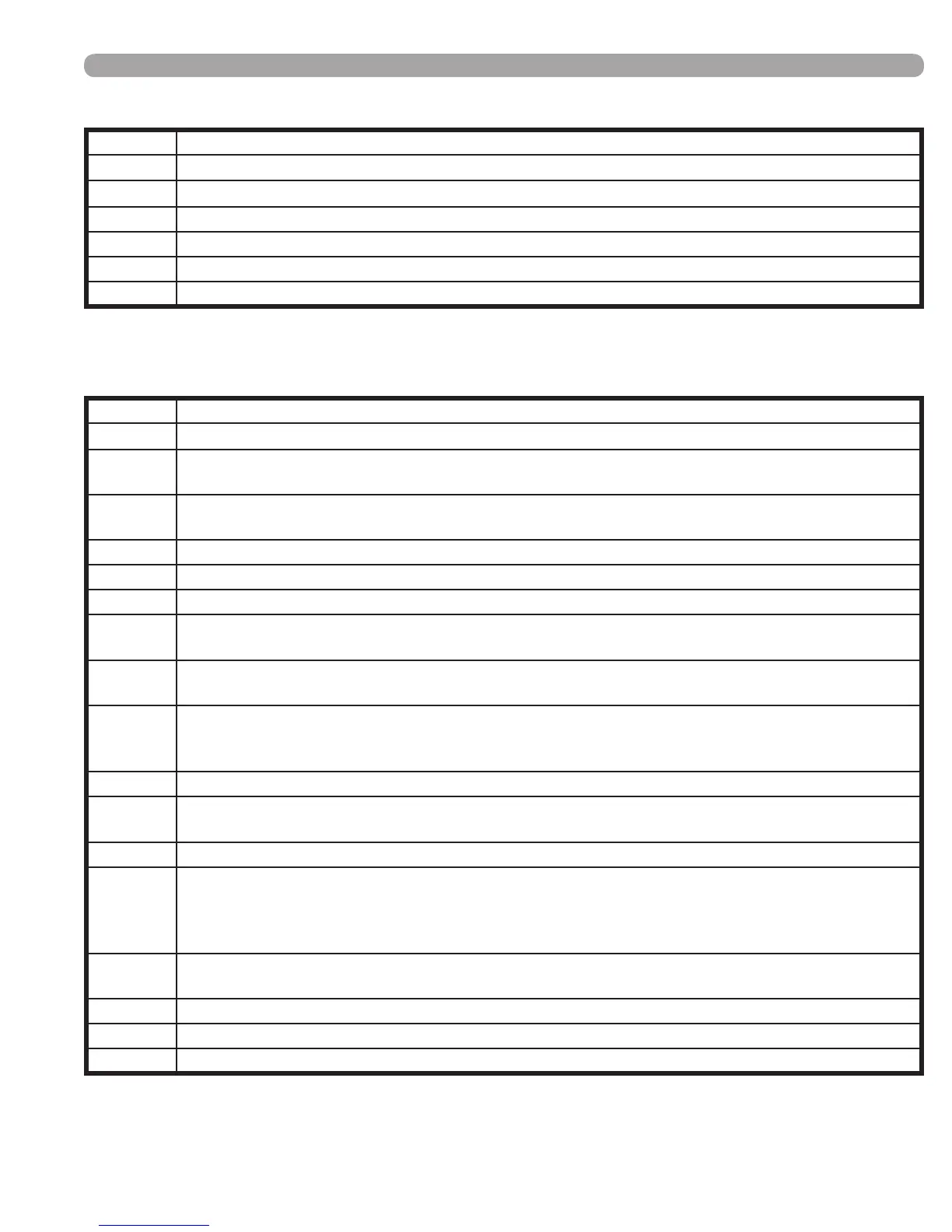

66. Gas valve not correctly adjusted at maximum load

67. Venting system has too much resistance (possibly partially blocked)

68. Setting of the pressure switch is incorrect (setting = 7mbar)

70. Electrical contacts are corroded

71. Wiring to switch is disconnected or incorrectly connected

72. Insufcient ow through the boiler

73. Heat exchanger is beginning to accumulate scale

SERVICING

(TABLE 7-5) FAULT CAUSES (CONTINUED)

The numbers given in Tables 7-3 and 7-4 match with those in the following table to troubleshoot.

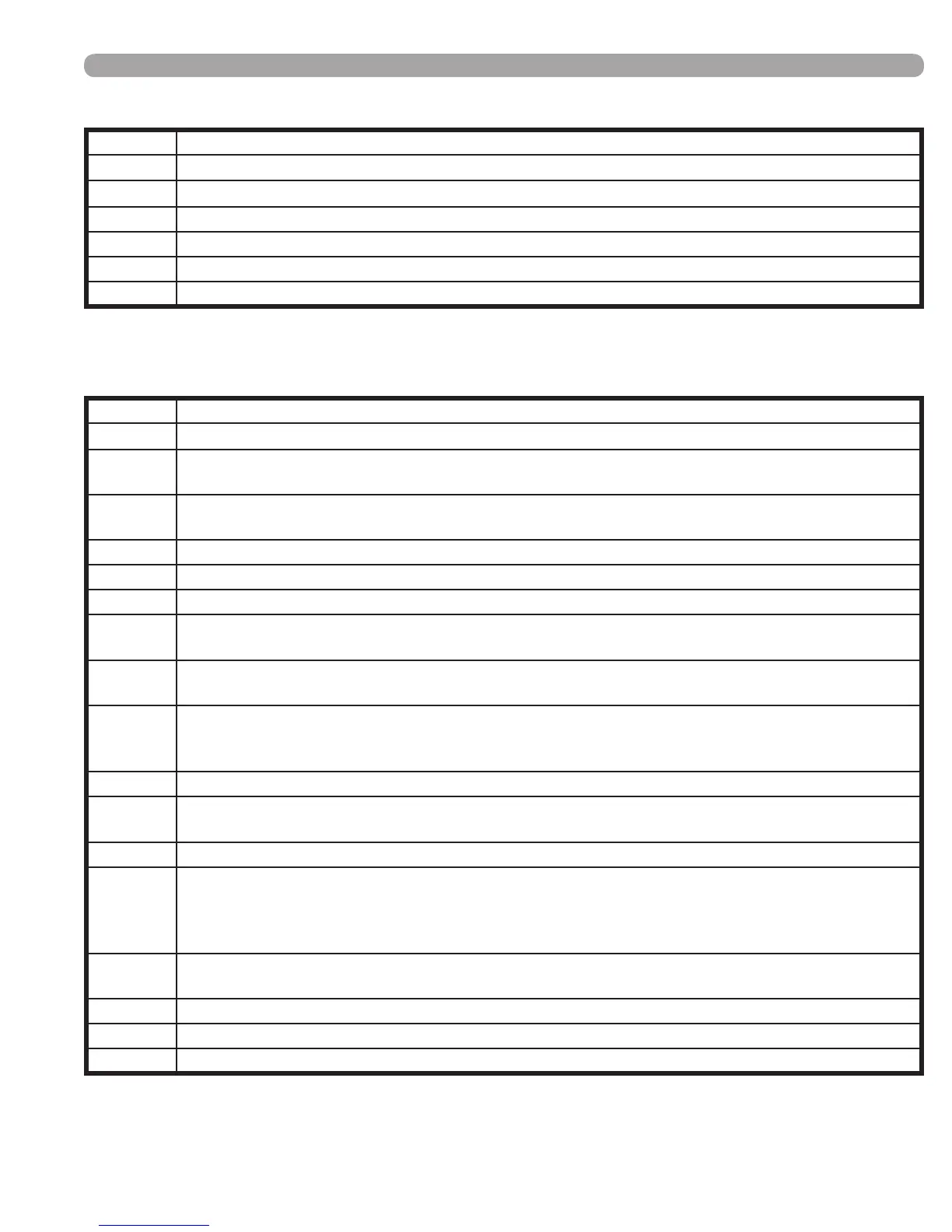

(TABLE 7-6) TROUBLESHOOTING THE FAULT

1. Flow and return line on the boiler have been changed around

4. Try to loosen the pump spindle, or replace the pump drive

5.

Check available city water pressure - water heater must be over 15 PSI. Boiler closed loop

heater system must have at least 12 PSI from ll valve. Check operation of expansion tank.

7.

Remove and reconnect the wiring harness, being sure that the plus lines up properly and latches

when fully inserted

8. Clean the fan blades

9. Replace the fan - see notes below under 13

10. Open gas valve

11.

Check line, gas meter, and pressure to heater inlet (it must be at least 4 inches WC). Make a

pressure drop test and calculation, as required.

12.

Change gas lines. If a exible connector is used, it must be rated for the BTU capacity of the appliance.

CONNECTORS PURCHASED AT HOME CENTERS WILL NOT WORK!

13.

Replace fuse. Check the fan; moisture will short circuit across the plug or wiring. The fan should

run at maximum speed by undoing the fan plug (speed control) with the 4 wires. If it does not,

replace the fan. If it does, check the wiring harness and connections.

16. See pages 11-13

18.

Check cable and cap for shorting to ground, overheating, and cut or worn cable casing. Check

spark ignitor porcelain for cracks. Check for 3/8” gap at electrodes.

21. Check that the plug(s) are tting tightly

22.

Open the condensate trap and clean out (underneath the appliance in the center) by unscrew-

ing the cap. Keep a jug on hand to catch the water drained. Look through the drained material

for contaminants. If there are alot, take the burner unit from the appliance as required, and pour

some water in the heat exchanger to rinse out the drain line

23.

Bleed all air from not only the appliance itself, but the entire system. If working on a closed loop

heating system, take care not to run the pumps if there is no water

25. Check the inlet air and ue lines for blockage

26. Check the inlet and ue system starting at the appliance outlet

28. Check all shut off valves and check valves. Be sure they are fully open.

Page 29 of 50

Loading...

Loading...