34000 Autry Street, Livonia, MI 48150 • 800.968.5530 • Fax 734.419.0209 • www.hamiltonengineering.com • LIT91127 REV 3/09

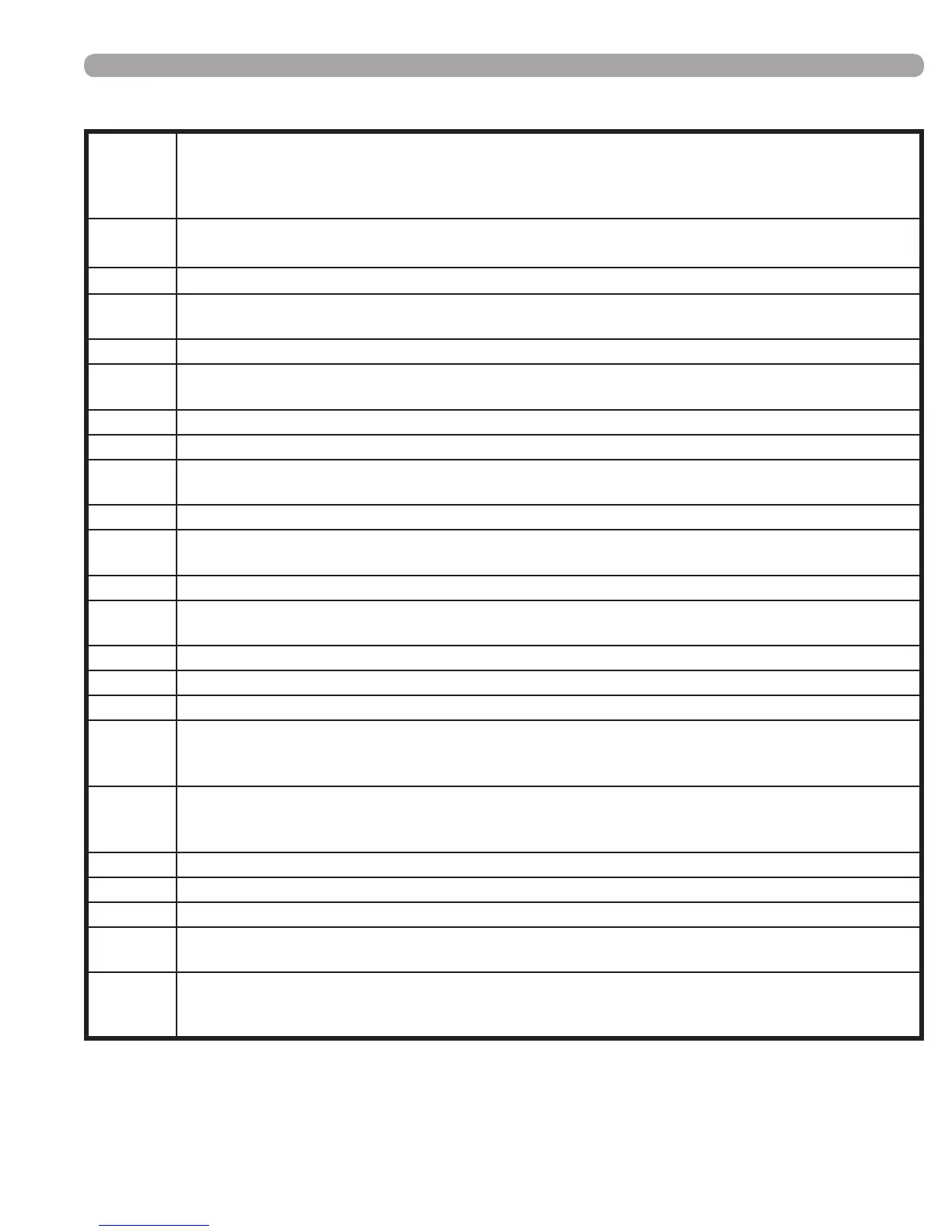

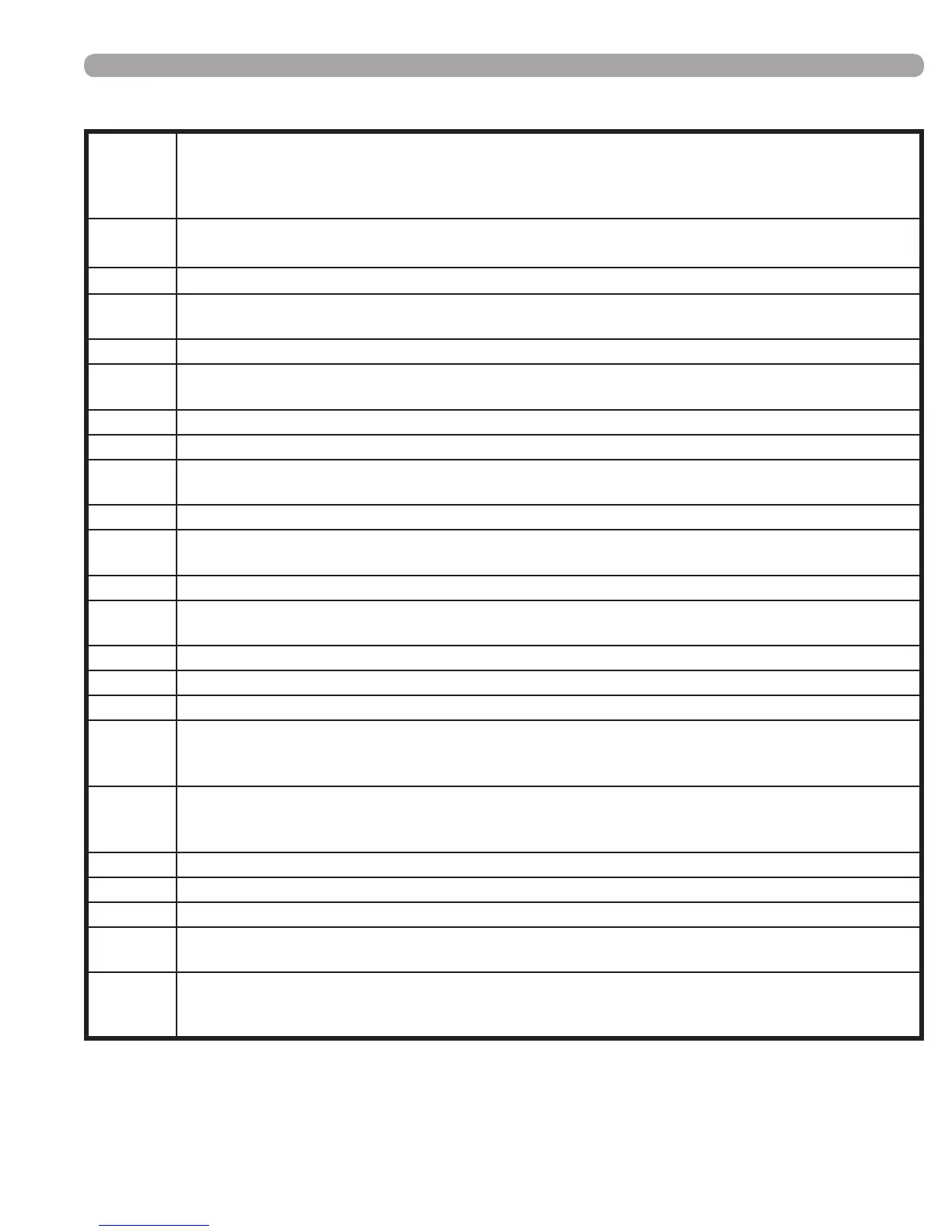

29.

First check that the pump is circulating like it should, that there are no obstacles between the

appliance and the tank (or in any of the inlet/outlet piping), and that the appliance is still making

noise. Then the heat exchanger will need to be acid cleaned.

DO NOT RUN THE APPLIANCE UNTIL THIS IS DONE!

30.

Replace the high-limit thermostat by unscrewing it from the brass nut; no draining is needed (do

not remove the brass nut)

31. Go over the Fan RPM settings as outlined in Table 3-4 on page 12-13

35.

Replace. Or when bending, take care: bend near the burner plate, or there may be

risk of cracking

39. Remove the connection and blow dry using a hair dryer or compressed air

40.

The plug wire connection must point to the outside of the fan. One side should t into the groove

on the PCB

41. Check the plugs and t into one another correctly

42. Check cables for possible damage or entrapment, and replace as required

44.

Check the seal of the heat exchanger on the ue gas casing, and replace as required. Fit a new

rotary lip seal. Lift the ue gas tube and inspect the Non-Return Valve from the top

45. Check the ow and DHW lines

46.

Disconnect leads from sensor and place an OHM meter across both terminals on

the sensor. Compare to Figure 7-1 on page 32. If it does not match, replace

51. Contact Hamilton Engineering for assistance at 800.968.5530

52.

Check the type of room thermostat and contact Hamilton Engineering for assistance at

800.968.5530

53. Contact Hamilton Engineering for assistance at 800.968.5530

54. Change the “wake-up” times of the clock thermostat

57. Check the sensor on the storage tank or in the common piping

60.

It may occur that the 18-pin FMT 914 plug moved up one pin too far—this may cause a fault in

the communication between the wiring and the pins. Check both the left and the right-hand side

of the plugs to ensure they are placed correctly

61.

A defective gas valve usually has one of the two causes: the electric coils are

defective, or an internal defect to the gas valve. In either case, it is recommended

to replace the entire gas valve

63. Contact Hamilton Engineering for assistance at 800.968.5530

66. Re-adjust the gas valve per the instructions on pages 11-13

67. Check the venting system completely for blockage

68.

If the setting is correct and all possible causes of blocked ue or condensate drain system have

been eliminated, replace the pressure switch

69.

When there is water in the tube, there must be a leakage by one of the connections (air can

escape through this leak), and inspect the tube for small cracks. Replace the plastic tube as

needed.

SERVICING

(TABLE 7-6) TROUBLESHOOTING THE FAULT (CONTINUED)

Page 30 of 50

Loading...

Loading...