V10k automatic 4. Installation

13

EN

The injection tube consists of a pvc stop valve

and a tube with threaded connection, that

extends to approx. 1/3 of the mains diameter

when extended.

It is recommended that all solution delivery

lines be fitted with a suitable valve and drain

pipe to enable any pressure build up to be

safely released prior to maintenance work.

4.3.4 Water supply

To operate the injector, a water supply pipe of

at least 3/4“ diameter is necessary according

to the operating conditions.

There must always be sufficient operating

water available at an adequate supply pres-

sure (see Technical Data for details). The ope-

rating water must not contain any particulates

(potable water quality).

Water pressure and quantity depend on the

maximum dosing capacity, the counterpres-

sure at the point of application, the difference

in geodetic altitude between chlorinator and

point of application and the friction in the

dosage line. On these values depend the selec-

tion of the injector.

If the operating water pressure is too low, a

booster pump is required.

The water line should include a suitable shut-

off valve, strainer, pressure gauge, pressure

reducing valve check-valve and solenoid valve

(see chapter 7.1).

It is recommended that all solution delivery

lines lines be fitted with a suitable valve and

drain pipe to enable any pressure build up to

be safely released prior to maintenance work.

4.4 Gas supply line

For reducing the pressure from the chlorine

tanks, a vacuum control valve and a safety

relief valve are necessary (see also typical ins-

tallation).

For the vacuum control valves a separate inst-

ruction manual „Gas supply“ is available.

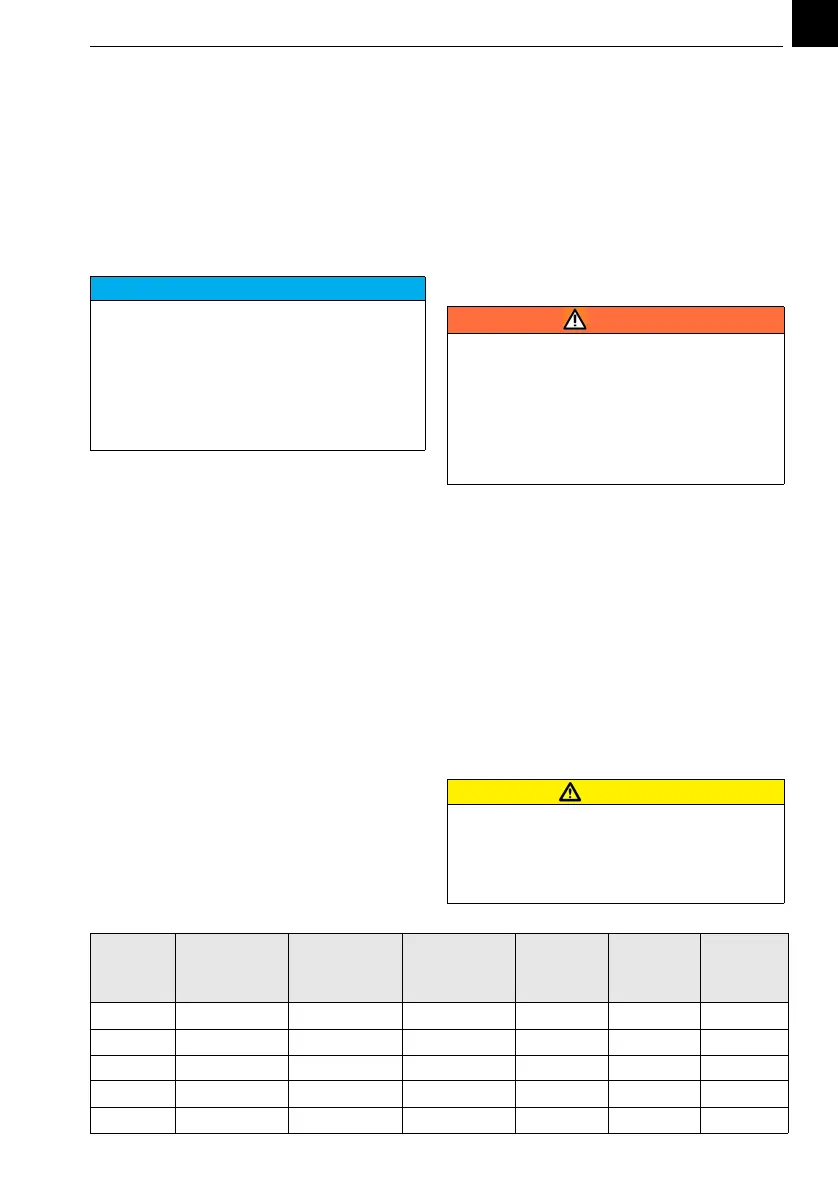

4.4.1 Gas suction line

The diameter of the suction line between

vacuum control valve, control unit and injector

depends on the the gas flow and the distance

(see table below).

Max. tube/pipe length from vacuum control valve to the V10k

NOTICE

Behind the point-of-application a pipe

length of at least 10...15 x pipe diameter is

necessary for a homogenious mixing of the

solution into the main water. After that,

samples can be taken for residue control

etc. If the point-of-application is into a basin,

channel etc. a diffusor can be supplied (refer

to the project documentation.

WARNING

Danger due to chlorine gas !

The gas control unit must be connected to a

vacuum gas supply only.

Do not open the cylinder or drum valve until

the system has been fully installed and the

pre-start checks are being carried out.

Refer to the safety information of the gas

supplier and the safety data sheet!

ATTENTION

When using polyethylene pipes don't install

them in narrow, badly vented protection

pipes or in the ground to prevent the pipe

from fast embrittling under the influence of

chlorine.

Feed of

Cl2, SO2

in g/h

PE hose

6,35 mm

(1/4“)

PE hose

9,5 mm

(3/8“)

PE hose

12 mm

(1/2“)

PVC pipe

DN 15

PVC pipe

DN 20

PVC pipe

DN 25

200 250 m 1200 m 3000 m - - -

400 146 m 670 m 1510 m 3600 m - -

1000 24 m 88 m 852 m 1710 m - -

2000 6 m 33 m 107 m 320 m 1094 m -

3000 3 m 16 m 53 m 179 m 607 m 1853 m

Loading...

Loading...